The military and defense industry has incredibly high standards for their equipment, and this extends up the supply chain to the fabricators who produce parts and components. Achieving this level of quality is no simple task; it requires a continuous commitment to excellence, a deep understanding of materials and fabrication, and proven processes that ensure quality in every aspect of production and operations.

As an ITAR-registered custom fabrication shop, Approved Sheet Metal is relentlessly committed to quality and precision, especially when fabricating parts for military and defense applications. Over the past 30 years, we’ve honed our expertise in sheet metal fabrication, and with a broad range of in-house capabilities, have established ourselves as a trusted partner for the defense industry’s sheet metal prototyping and low-volume production needs.

Table of Contents

Custom Sheet Metal Fabrication for Military and Defense Applications

The U.S. military relies on custom sheet metal parts in countless operations and applications. Whether it’s components used on military bases, in vehicles, or in the field, we provide the precision fabrication capabilities that the military requires.

Some of the sheet metal parts we often fabricate for military and defense applications include:

Enclosures and Housings

We have extensive experience fabricating enclosures and housings that provide weather-resistant protection for electronics, communication devices, radar, and sensors. For sensitive electronic components, our expertise includes incorporating EMI/RFI shielding into housing assemblies, so that interference never compromises performance in critical applications.

With integrated slot-and-tab designs to enhance assembly accuracy and structural integrity, our precision-fabricated enclosures and housings are designed to provide long-term reliability even in harsh operational conditions.

Brackets and Mounts

Using techniques like forming and punching, we fabricate mission-critical brackets and mounts for a wide range of applications, including weapons systems, vehicles, antennas, sensors, and aerospace systems.

To ensure that each bracket and mount offers the necessary strength and reliability, we use materials such as cold-rolled steel, stainless steel, and aluminum that meet MIL-SPEC standards. Additionally, finishing options like powder coating, passivation, and anodizing offer enhanced corrosion resistance and durability for parts with critical applications.

Chassis and Frames

Leveraging our sheet metal forming and welding capabilities, we fabricate robust structural frames and chassis for avionics and ground systems, as well as lightweight aluminum and stainless steel frames for numerous applications. To verify that every chassis and frame meets the military’s high standards for strength, durability, and precision, we perform rigorous quality inspections to deliver frames that are structurally sound and ready for integration.

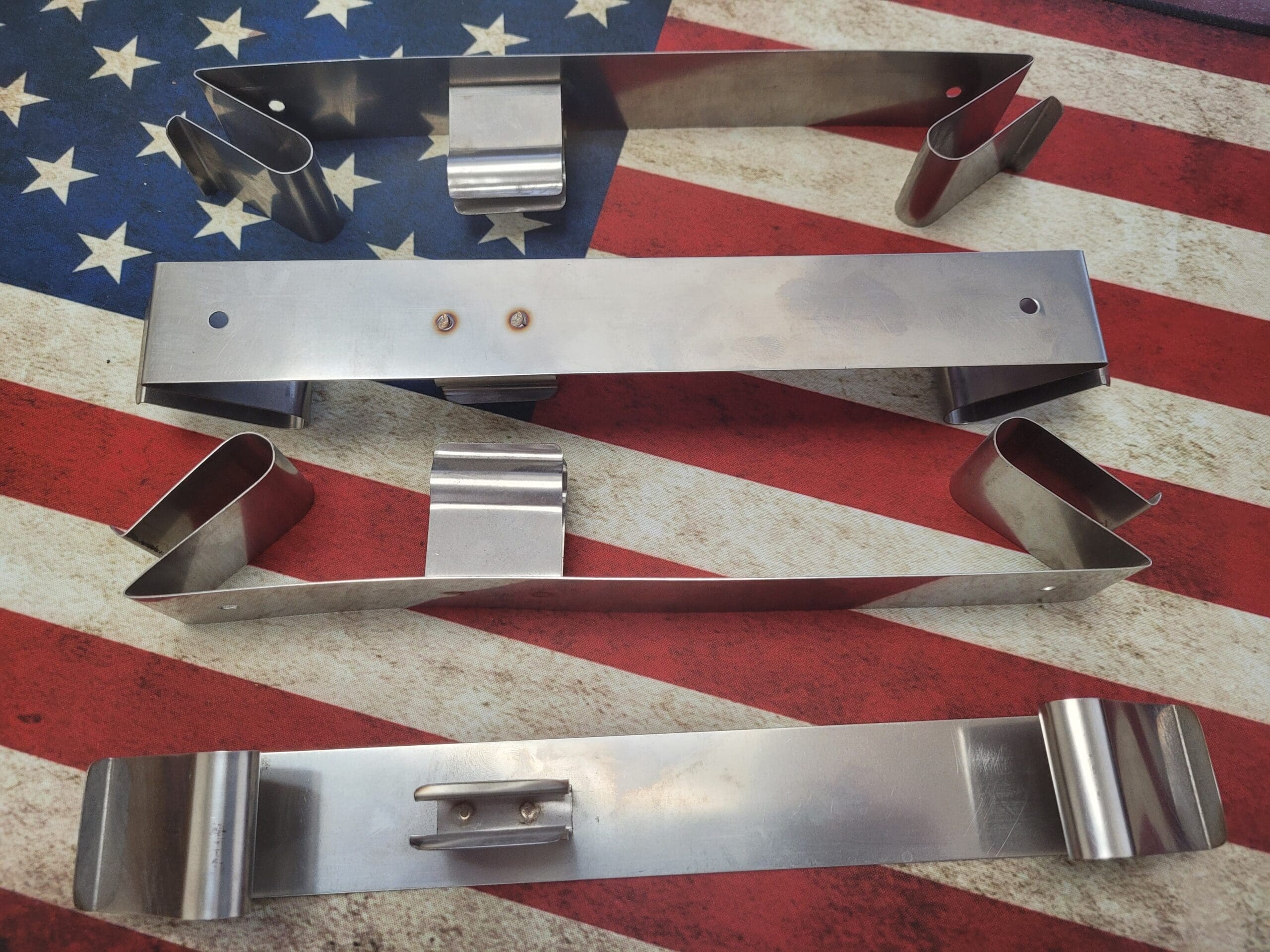

Heat Shields and Thermal Barriers

With our experience in industrial sheet metal fabrication, defense customers rely on us to produce durable engine heat shields and exhaust system covers for military vehicles, as well as thermal management components for electronics systems. Customized for each application’s specific requirements, our durable heat shields and thermal barriers are intended to withstand the extreme thermal cycling and vibration that can occur in military and defense operations.

Custom Covers and Panels

Utilizing metal fabrication processes like laser cutting, punching, forming, and welding, we fabricate custom sheet metal covers and panels that are designed to meet the rigorous demands of the defense industry. Fabricated from materials like aluminum and stainless steel to offer protection from environmental factors and wear, every cover and panel we fabricate is mission-ready and engineered to exacting specifications.

UAV and Drone Components

Drawing upon our deep expertise in precision sheet metal fabrication for the aerospace industry, we produce a variety of strong yet lightweight parts for unmanned aerial vehicles (UAVs) and drones. From internal components to exterior body panels, we leverage advanced aerospace-grade materials like 5052-H32 aluminum to fabricate parts with high strength-to-weight ratios critical for flight performance.

High-Grade Materials for Durable Military and Defense Components

In precision metal fabrication, there’s an extensive range of materials to choose from depending on your part’s design and its intended operating environment. For parts with military and defense applications, we often utilize materials like:

Aluminum: Lightweight, cost-effective, and compatible with many finishing processes, aluminum is available in various alloys. However, aluminum 5052 is the top choice for most parts, particularly enclosures, brackets, and aerospace components that require forming.

Stainless Steel: Strong, durable, and resistant to rust and corrosion, stainless steel is ideal for fabricating many military and defense components, particularly chassis, frames, and other parts exposed to harsh environments.

Carbon Steel: Equally robust and often more cost-effective than stainless steel, carbon steel is excellent for sheet metal fabrication. However, it does require additional finishing processes, such as powder coating, to prevent rust and corrosion.

Copper: Ductile and an effective conductor of both heat and electricity, copper is often used to fabricate electrical contacts and shielding, and it is also a key component of thermal management systems.

Precision Fabrication Processes for Robust, Military-Grade Parts

Whether you’re looking for a partner for prototype fabrication or low-volume production, at Approved Sheet Metal, we leverage our expertise and capabilities to provide reliable, cost-effective solutions and achieve mil-spec standards at all production volumes.

Extensive Custom Metal Fabrication Capabilities

Depending on the type of parts and their design specifications, custom parts for the military and defense industry can involve a variety of processes. At Approved Sheet Metal, our extensive in-house capabilities include laser cutting, punching, and forming, creating a single-shop solution for the wide range of sheet metal parts and components the military requires.

High-Quality Sheet Metal Finishing

Durability is a key component in fabricating parts that meet the defense industry’s unique needs, and the correct finishing process is essential for resistance to harsh environmental conditions. While a high-quality raw metal finish is suitable for many parts that aren’t exposed to the elements, more elaborate finishing processes are often required for enhanced protection and longevity.

However, with our in-house capabilities and those of our vetted vendor network, we can achieve an optimal finish on every part, even for those that must withstand the most demanding and intense environments.

Comprehensive Assembly Services

Many of the parts the military relies on require at least some degree of assembly. As a full-service sheet metal fabricator, we leverage our welding expertise, hardware installation capabilities, and comprehensive assembly services to fabricate complex assembled components and finished functional products.

Your Military and Defense Sheet Metal Fabrication Partner

With the critical nature of many military and defense parts, it’s essential to work with a fabrication partner that has deep experience meeting the industry’s needs.

At Approved Sheet Metal, we know what it takes to produce the high-quality parts that the military needs. With our ISO 9001:2015 certification, you can have confidence that all of our processes have been intentionally designed to result in the highest-quality precision parts possible. Additionally, as an ITAR-registered fabrication company, we’re approved to produce parts for military and defense applications and securely handle all of the corresponding data, including part designs and specifications.

If you require a sheet metal fabrication partner with proven experience in serving these industries, request a quote or contact us today.