Forming Sheet Metal Parts

Sheet metal forming is the process of shaping a sheet of metal into parts by bending or drawing it. This process can be done using a variety of methods, but the most common method is through a press brake. A press brake is a machine that uses a die to create the desired shape in the sheet metal. The sheet metal is placed between the upper and lower dies, and the dies are then brought together to form the metal into the desired shape. Bending and forming sheet metal is a popular method for creating custom parts, as it allows for a high degree of precision. Parts that are made through metal forming can have very tight tolerances and be made to very specific shapes. As a result, press brake forming is an essential process for many industries that require precision parts.

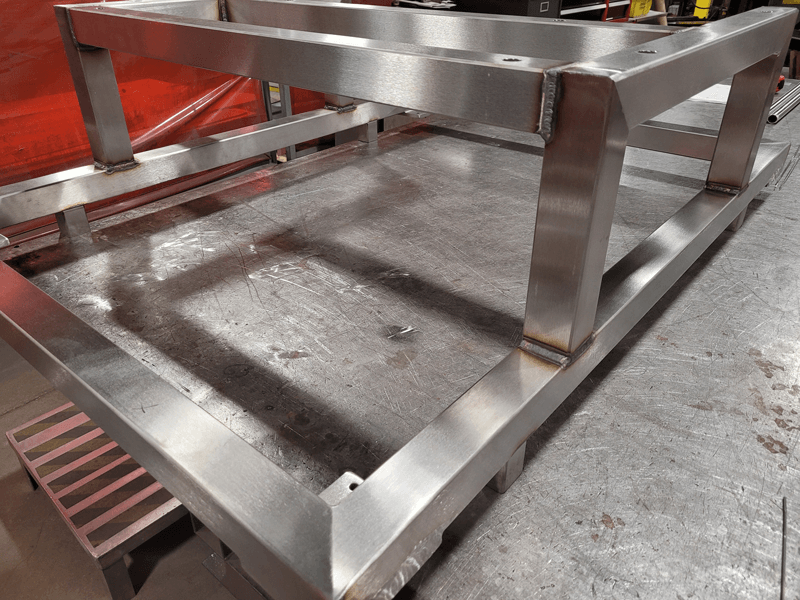

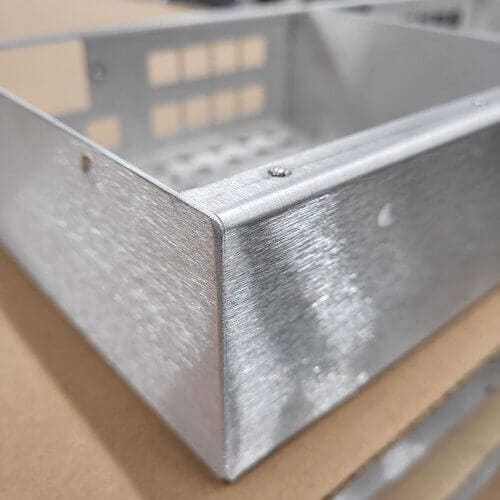

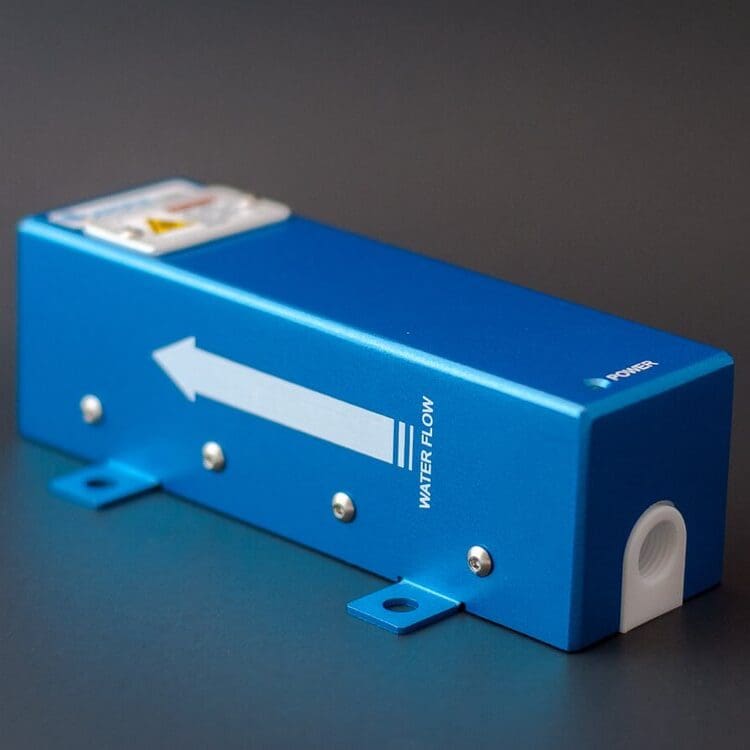

When it comes to sheet metal fabrication, custom forming is an essential technique for creating components with specific shapes and properties. At Approved Sheet Metal, our forming services can guarantee precision and repeatability, ensuring that each part meets the specifications required for your project. This can save time and money on rework, as well as improve the overall function of your end product. In addition, our in-house tooling capabilities allow us to quickly design and create custom tools for unique formed sheet metal projects, offering a cost-effective solution for specialized parts. With our combination of expertise and advanced equipment, we're able to provide high-quality forming services that add value to your project.

Our press brake operators have 15+ years of experience in forming prototypes to low-volume production quantities. In addition to forming, other sheet metal fabrication capabilities that Approved Sheet Metal has extensive experience in include:

- Punch Forming

- Laser Cutting

- Welding

- Hardware Insertion

- Assembly

- Powder Coating, Silk Screening, Plating and more.

Check out the gallery below to see what we can do for you!

Frequently Asked Questions (FAQS)

What is your lead time for formed sheet metal parts?

Standard ship for formed parts is 7-10 days, with expedites available!

What tolerances can you achieve for formed parts?

We can achieve tolerances of +/- 0.003”

What considerations should I think about when designing parts?

There are ways to design parts, and specific features, that will help reduce back-and-forth and ensure that you get what you need out of your part. Take a look at our Sheet Metal Design for Manufacturing eBook to see best practices - See the eBook