Quick Turn Prototype Sheet Metal Fabrication - We Love Quantity 1

Prototype Sheet Metal Fabricator - Expedites ALWAYS Available

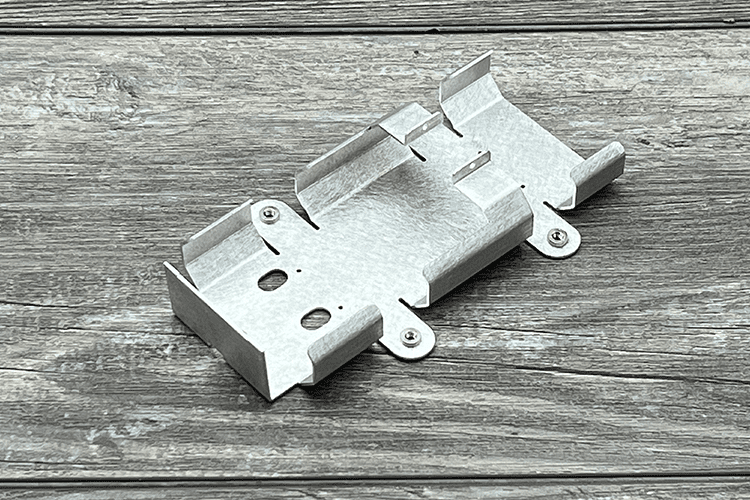

Prototype sheet metal parts on your dock in just days. Hand sketches, detailed prints, and CAD models, we take it all. Turn your idea into physical precision fabricated sheet metal parts. We understand how important it is to hit that deadline and we are committed to supporting your journey from design to parts. We are sheet metal prototyping experts who get it.

30+ years of experience, 25,000+ sq. feet of precision sheet metal manufacturing space, state-of-the-art processes & equipment. From quoting to programming to punching, forming, hardware insertion, welding, finishing, and inspection. We treat every job with a sense of urgency because we know that you are in a race to get to the market first.

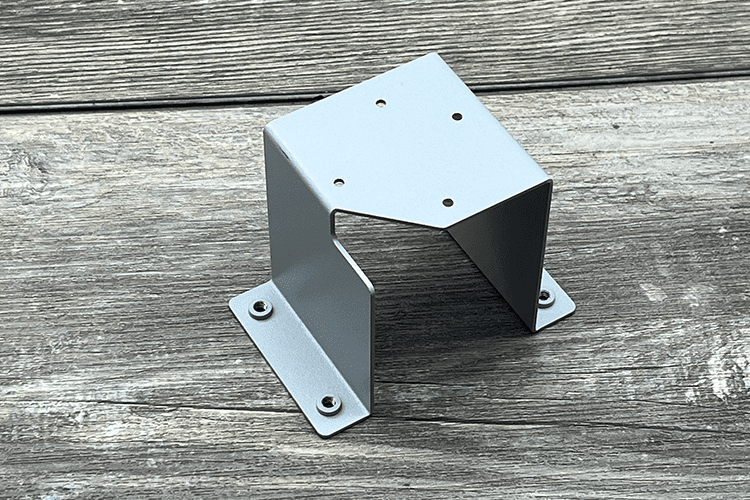

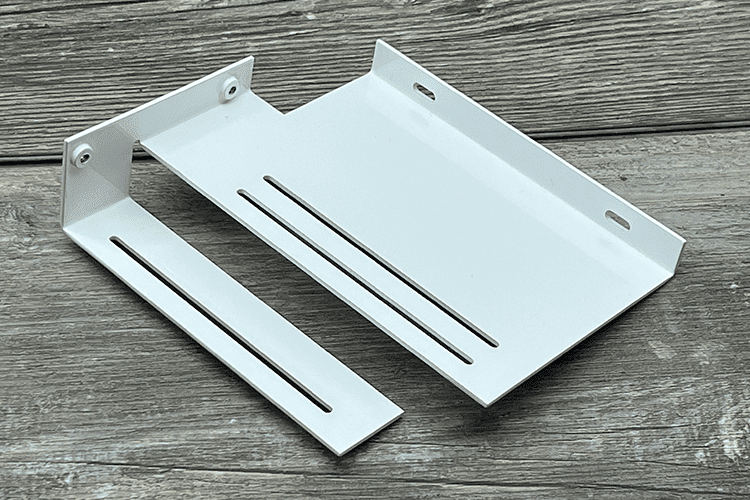

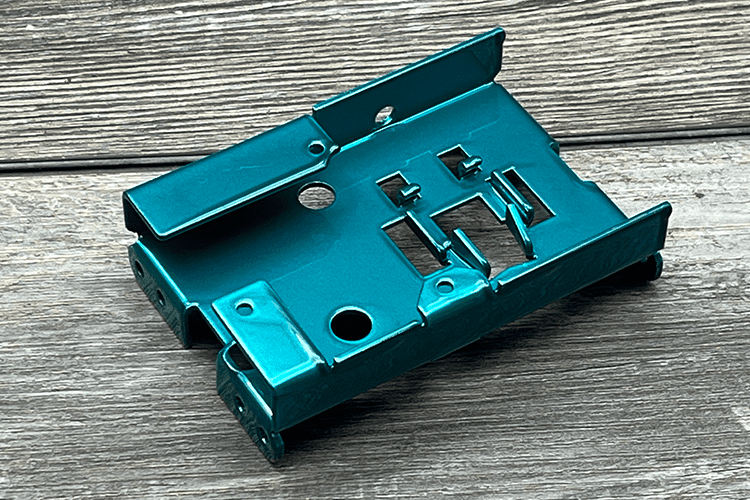

Our prototype fabrication services help to create parts and products quickly and efficiently. By using advanced technologies, such as laser cutting and CNC bending, ASM is able to create complex shapes and designs with a high degree of accuracy. Our prototype services can be used to create prototypes of new products or to test out new manufacturing processes. By working with ASM for your prototype needs, you can be assured that your prototypes will meet the highest standards of precision.

We WILL excel at fabricating your prototype parts. When you are ready to scale to low-volume production we are here to get to work for you. We have equipment that is dedicated to running larger volume jobs, this means that we have the capacity to meet prototyping and production sheet metal requirements simultaneously. Learn more here.

Rapid Sheet Metal Prototyping Service Capabilities

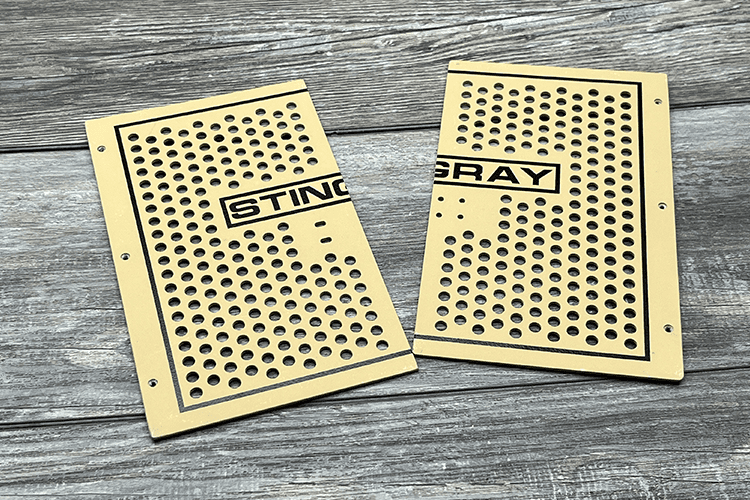

From triple axis CNC press brakes to punch presses with auto-loading turrets that handle the smallest to the largest parts. Our shop is built so jobs flow smoothly through the shop and arrive at your desk on time and to your specifications. At our state-of-the-art sheet metal fabrication facility, we offer a wide range of capabilities and services to meet the needs of product developers across the US. We are equipped with the latest forming and bending technology, allowing us to produce precision parts with complex geometries. In addition, we offer a variety of finishes, including powder coating, plating, and anodizing. We also offer dedicated laser cutting, punching, and forming services. Our team of skilled engineers and technicians is dedicated to providing our customers with the highest quality parts and excellent customer service. Whether you need a few prototypes or a low volume production run, we are your one-stop shop for all your sheet metal fabrication needs. Contact us today for a free quote!

Laser Cutting | Punching | Forming | Welding / Spot Welding | Hardware Insertion | Assembly

Finishing

Prototype parts that require powder coating is routine for us. We leverage long-standing relationships with local suppliers for common and special coatings for your sheet metal parts.

- Standard Raw Finish Options

- Powder Coating & Silk Screening

- Anodize & Chromate

- Sandblasting

Editing the Sheet Metal Default Bend Radius, Bend Allowance, Bend Deduction, or Relief Type in SOLIDWORKS

Converting a Solid Part to a Sheet Metal Part in SOLIDWORKS (Updated for 2024)

Prototype Sheet Metal Fabrication That Won’t Break the Bank: 5 Tips for Startups (Updated for 2025)

Optimizing Sheet Metal Designs: 5 Tips for Mechanical Engineers (Updated for 2026)

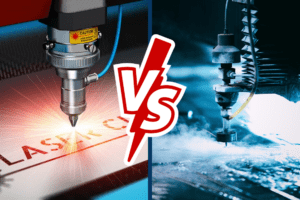

Cutting Through the Confusion: Laser Cutting vs. Waterjet Cutting for Sheet Metal Fabrication (Updated for 2025)

Industries Served

Aerospace | Automotive | Communications | Electronics | Instrumentation | Medical | Miscellaneous Metals | Robotics