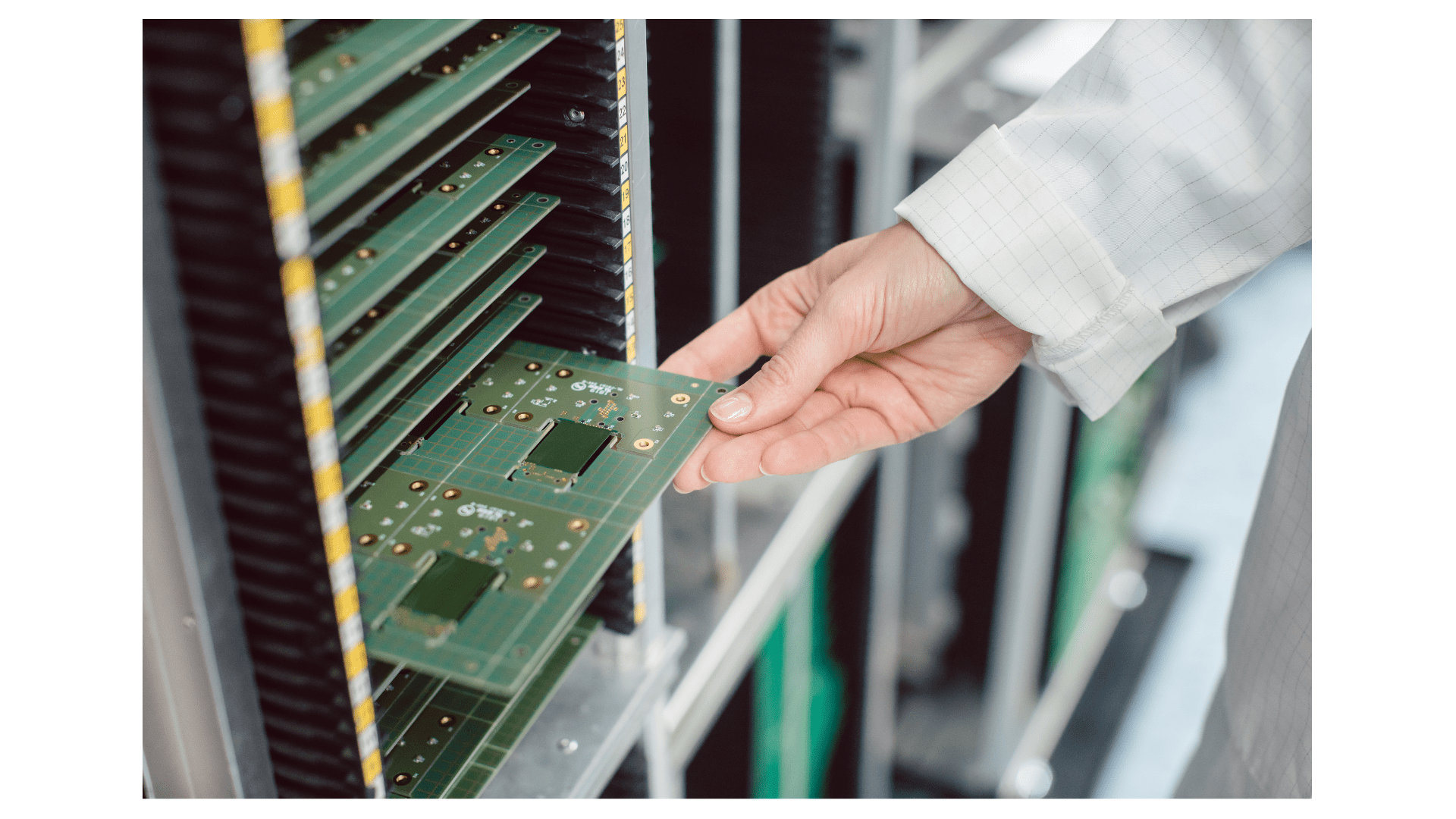

Electronic circuit boards, also known as printed circuit boards (PCBs), power systems across nearly every industry. To protect these components and ensure optimal performance, high-quality card cages are essential. Though off-the-shelf card cages may be sufficient in some situations, custom sheet metal card cages provide a more robust and reliable solution for circuit boards with critical applications.

At Approved Sheet Metal, we offer a range of customization options to help you achieve the right fit and function for your PCB. Whether you need application-specific mounting components, integrated EMI shielding, or specialized cooling and airflow features, our team can fabricate a solution tailored to your exact requirements.

Table of Contents

Custom Sheet Metal Fabrication Options for Card Cages

While PCBs may appear superficially similar at a glance, they can vary significantly in their size, mounting requirements, connector placement, and more. Off-the-shelf card cages are unlikely to account for all of your board’s specific features, especially if you’re dealing with multi-board systems or boards that rely on high-speed connectors for enhanced performance.

While PCBs may appear superficially similar at a glance, they can vary significantly in their size, mounting requirements, connector placement, and more. Off-the-shelf card cages are unlikely to account for all of your board’s specific features, especially if you’re dealing with multi-board systems or boards that rely on high-speed connectors for enhanced performance.

By working with a custom sheet metal fabrication partner, you can design circuit board card cages to precise specifications, incorporating numerous features that will ensure long-term, reliable performance.

Precision Fabrication Tailored to Your Boards

One major advantage of custom card cage fabrication is the precision it allows. Not only can we fabricate card cages to your exact dimensions, but we also account for connector layout and mounting requirements, as well. That means your housing will be stable and perfectly aligned.

In addition to offering a precise, board-specific fit, we can fabricate card cages with removable panels for tool-free access and easy assembly. That makes it simple to swap out PCBs if you ever need to service, upgrade, or replace your boards.

✅ Design Tip: Provide the exact dimensions and desired spacing between cards, and include any backplane or connector positions that impact layout. You may also want to incorporate universal card slot spacing, adjustable guide rails, or removable sections.

Durable Materials for Diverse Applications

When selecting the right material for your custom card cage, it’s important to balance performance requirements with factors like weight, durability, cost, and environmental conditions. Depending on your application, there are several common materials to choose from that may provide the best results for your specific needs:

Aluminum: By far the most common and cost-effective material for fabricating card cages, aluminum is lightweight, corrosion-resistant, and offers excellent thermal conductivity to dissipate heat. Aluminum fabrication is the standard for card cages in applications where weight and heat dissipation are critical, particularly within the aerospace, telecommunications, and high-performance computing industries.

Cold-Rolled Steel: If durability is a priority, cold-rolled steel is an excellent option that’s suitable for more rugged applications. However, cold-rolled steel is significantly heavier than aluminum, and powder coating or plating is required to prevent corrosion. For these reasons, cold-rolled steel card cages are principally used for industrial electronics or defense applications.

Stainless Steel: While more expensive than aluminum or cold-rolled steel, stainless steel fabrication offers exceptional durability and corrosion resistance, making it an ideal option for card cages that are incorporated into medical devices or operate within harsh environments.

EMI Shielding for Interference-Free Performance

EMI/RFI shielding can be critical to card cages in certain applications, preventing electronic noise from interfering with internal circuit boards or nearby devices. Certain standards, including FCC, CE, and MIL-STD-461, require shielding for compliance.

While many off-the-shelf card cages include EMI/RFI shielding, with custom fabrication, we can enhance EMI/RFI resistance by applying specialty coatings, as well as incorporating EMI gaskets into the design.

✅ Design Tip: Remember to call out grounding points, conductive finishes, and EMI gaskets—these impact several aspects of fabrication.

Integrated Thermal Management for Long-Term Reliability

Thermal management is another major factor in card cage fabrication. Without proper thermal management and ventilation, electronic circuit boards can overheat, which can impact performance, damage the board, or even result in sudden failure.

To prevent these issues, we offer various ventilation and thermal management options, including perforated panels, louvers, fans, heat sinks, and airflow channels. The right solution depends on your application, but each option is designed to prevent overheating and extend your system’s lifespan.

✅ Design Tip: Note whether fans, vents, louvers, or heat sinks are required in your design specifications, as proper ventilation planning is less expensive to integrate before fabrication.

Custom Finishing for Enhanced Durability

There are a variety of finishing options available to ensure a high-quality appearance and protection for your circuit boards:

Aluminum Card Cage Finishing: For aluminum card cages, anodizing is an ideal finish that improves aesthetics, enhances resistance to corrosion, and creates an electrically insulating surface. Chem film is another option that also provides corrosion resistance while creating a surface that’s paintable for brand- or application-specific requirements.

Cold-Rolled Steel Finishing: If you require a cold-rolled steel card cage for more rugged applications, powder coating is excellent for corrosion resistance. Your PCBs will remain protected from moisture and humidity, even in harsh environments.

✅ Design Tip: Always remember to specify your finishing requirements, as these affect lead time, cost, and functionality.

Custom Card Cage Fabrication That Meets Exacting Standards

For long-term, interference-free performance, custom sheet metal fabrication is the right choice for card cages. However, with so many options to consider, partnering with an experienced custom fabrication shop like Approved Sheet Metal is crucial to achieving the best results. With our comprehensive fabrication services, we’ll help you evaluate your options and deliver the custom circuit board card cages you need.

Want to learn more about our card cage fabrication services? Reach out and request a quote today.