Last updated on February 9th, 2026 at 08:54 am

The world’s most abundant metal, aluminum, is used across countless industries and it has been a staple material at Approved Sheet Metal for years. In sheet metal fabrication, aluminum behaves differently than it does in machining. Alloy selection, bend radius, gauges, and joining methods can determine whether a part forms cleanly or cracks, distorts, or requires redesign.

Below are four practical, shop-floor facts that can help you choose the right aluminum and avoid common quoting and manufacturing issues, especially for prototype and low-volume production work.

Table of Contents

- 1 What’s Your Aluminum IQ?

- 1.1 1. 5052 aluminum is the best choice for both prototype and low volume production sheet metal fabrication services

- 1.2 2. Aluminum is cost-effective and compatible with many finishing options

- 1.3 3. Welding aluminum requires a high level of expertise

- 1.4 4. Aluminum gauges differ from stainless steel gauges

- 2 Common Aluminum Alloys We Fabricate at Approved Sheet Metal

- 2.1 Additional Considerations for Aluminum Fabrication

- 2.1.1 1. Material Sourcing and Availability Trends

- 2.1.2 2. Environmental Impact and Sustainability

- 2.1.3 3. Thermal and Electrical Conductivity

- 2.1.4 4. Mechanical Properties in Specific Applications

- 2.1.5 5. Comparison with Competing Materials

- 2.1.6 6. Advanced Forming Techniques

- 2.1.7 7. Surface Finishes and Their Functions

- 2.1.8 8. Joining Methods Beyond Welding

- 2.1.9 9. Impact of Thickness on Performance

- 2.1.10 10. Common Mistakes in Aluminum Design

- 2.1 Additional Considerations for Aluminum Fabrication

- 3 Sheet Metal Design for Manufacturing

- 4 Aluminum for Sheet Metal Fabrication FAQ

- 4.0.1 What is the best aluminum grade for sheet metal fabrication services?

- 4.0.2 Is aluminum a cost-effective option for parts, and does it require additional finishing?

- 4.0.3 Is welding aluminum different from welding steel or stainless steel?

- 4.0.4 Are aluminum gauges the same as steel gauges?

- 4.0.5 What should I know about heat treating aluminum and its different alloys?

What’s Your Aluminum IQ?

How much do you know about aluminum for sheet metal fabrication? These key points focus on the differences that matter most when your part needs to be formed, finished, and assembled reliably.

1. 5052 aluminum is the best choice for both prototype and low volume production sheet metal fabrication services

When ordering aluminum parts, many customers request 6061 because it is a preferred grade for CNC machining. However, when it comes to sheet metal fabrication, 5052 is generally the best choice. 6061, especially in harder tempers, is more prone to cracking during forming, while 5052 is better suited for bends and formed features.

5052 is more readily available in sheets than 6061 or 7075, which often makes it easier to source. It is also more ductile than other grades, making it less likely to crack when forming a tight radius, hem, or offset. When possible, we recommend using 5052 for aluminum fabrication rather than more rigid grades, particularly when a design includes multiple bends or tight forming requirements.

2. Aluminum is cost-effective and compatible with many finishing options

If your budget is limited, aluminum may be the best choice for your parts. Aluminum is often less expensive to buy in sheet form than many alternative metals. Because it is naturally corrosion resistant, it may not require additional post-treatment purely to prevent rust in many indoor applications.

If you do wish to apply a finish, aluminum offers a wide range of options. Unlike stainless steel, it can be anodized and chromated, which can improve corrosion resistance, appearance, and downstream assembly performance depending on the application.

3. Welding aluminum requires a high level of expertise

Aluminum is harder to weld than steel or stainless steel because its material behavior can be less predictable during welding:

- Aluminum has high thermal conductivity, so heat moves quickly through the part and can create distortion or inconsistent weld profiles if heat input is not carefully controlled.

- Aluminum alloys are coated with an oxide layer that has an extremely high melting point. Specialized welding equipment and technique may be required to break through the oxide and achieve complete fusion.

However, if you need us to weld aluminum, we have you covered. Approved Sheet Metal has the expertise and the equipment to deliver excellent results.

(Note that in many cases, when welding is requested, fasteners may be a more efficient and cost-effective option. As we like to say, the best welding is often no welding.)

4. Aluminum gauges differ from stainless steel gauges

The gauges for ferrous metals like steel and stainless steel differ from the gauges for nonferrous metals such as aluminum. Steel and stainless steel use the Manufacturers’ Standard Gauge, while aluminum uses the Brown & Sharpe Gauge, also known as the American Wire Gauge.

For example, 10 gauge stainless steel has a gauge thickness listed at 0.134”, while 10 gauge aluminum has a gauge thickness listed at approximately 0.102”.

We recommend listing both the decimal dimension and the gauge in the title block of your drawing to avoid confusion. Better yet, supply a CAD-drawn 3D model along with your RFQ for maximum clarity and faster quoting.

Approved Sheet Metal 6061-T6 vs 5052-H32

Common Aluminum Alloys We Fabricate at Approved Sheet Metal

The most common alloy we use for aluminum fabrication is 5052. We also use 7075 and 6061, although not nearly as frequently. In sheet metal work, the best alloy depends on whether the part needs to form cleanly, maintain strength, weld reliably, or resist corrosion.

If you’re a regular reader of our blog, you may remember our Stainless vs. Galvanized Steel comparison, where the two steel types were evaluated across several performance categories.

Now, we will let the aluminum alloys 5052, 6061, and 7075 go head to head.

(You can think of this as the Lightweight Division, since aluminum weighs roughly one-third as much as steel.)

Which alloys perform best in strength, formability, weldability, and corrosion resistance? Let’s see how they compare.

Notes on Heat Treating Aluminum When it comes to heat treating aluminum, the temper has a direct impact on formability and cracking risk:

- 6061-T0: Annealed state that is easily formable and can be heat treated to T4 or T6 condition

- 6061-T4: Harder than T0 and easier to form than T6 while maintaining good strength

- 6061-T6: Excellent strength but harder to form and typically requires a much larger bend radius to prevent cracking

- 7075-T0: Annealed and easily formable, with the ability to be heat treated to T6 condition

- 7075-T6: Excellent strength but difficult to form and more likely to crack without generous bend radii

Additional Considerations for Aluminum Fabrication

Aluminum is a versatile and widely used material, but several additional factors can influence lead time, cost, and manufacturability in real-world fabrication.

1. Material Sourcing and Availability Trends

Aluminum availability can vary based on market conditions, demand, and supply chain disruptions. While 5052 is generally easier to source in sheet form, confirming lead times early can help prevent scheduling issues.

2. Environmental Impact and Sustainability

Aluminum is highly recyclable and supports sustainability goals by reducing material waste. In many applications, recycled aluminum content can be used without compromising performance.

3. Thermal and Electrical Conductivity

Aluminum’s high thermal and electrical conductivity makes it well suited for heat sinks, electronic enclosures, and conductive components. These same properties also affect forming and welding behavior.

4. Mechanical Properties in Specific Applications

Different aluminum alloys are commonly selected based on application requirements:

- 7075 Aluminum is commonly used in aerospace and defense applications due to its high strength.

- 6061 Aluminum is often chosen for structural and automotive components.

- 5052 Aluminum is frequently used in marine and industrial applications due to its corrosion resistance and formability.

5. Comparison with Competing Materials

While aluminum offers significant advantages, it is often compared with stainless steel, titanium, or composite materials. Aluminum’s low weight and favorable cost-to-performance ratio make it a strong option for weight-sensitive designs.

6. Advanced Forming Techniques

Processes such as hydroforming and deep drawing allow complex shapes to be produced with fewer seams. Aluminum’s formability can make it well suited for these methods when part geometry and production volumes justify the approach.

7. Surface Finishes and Their Functions

Aluminum supports a wide range of functional and cosmetic finishes:

- Anodizing: Adds a durable, corrosion-resistant surface and improves appearance.

- Chromating: Improves corrosion resistance and is commonly used in aerospace applications.

- Powder Coating: Adds protection and allows for color customization.

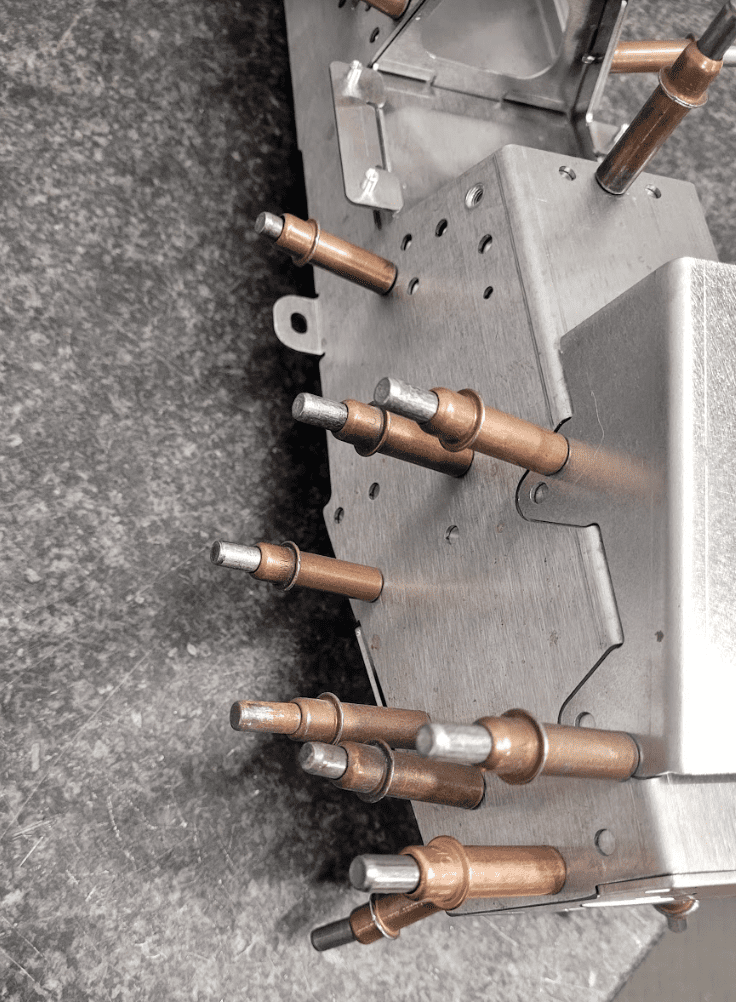

8. Joining Methods Beyond Welding

In many cases, adhesives, riveting, or mechanical fasteners such as PEM inserts can be more efficient than welding. These methods can reduce distortion and improve repeatability.

9. Impact of Thickness on Performance

Sheet thickness directly affects strength and formability:

- Thin sheets such as 0.040” are easier to bend but may require formed features or hardware to add stiffness.

- Thicker sheets such as 0.125” provide durability but require larger bend radii and higher forming forces.

10. Common Mistakes in Aluminum Design

Common design issues that increase cost or rework include:

- Specifying overly tight tolerances that increase machining and inspection effort.

- Placing features too close to edges, which can cause deformation during forming.

- Underestimating required bend radii for the selected alloy and temper.

Did we mention that we offer same-day availability for all of our aluminum alloys? Check out our full range of inventory and our same-day materials. Then, go ahead and request a quote.