Last updated on January 9th, 2026 at 07:37 pm

Price matters in every purchasing decision. But when sourcing precision sheet metal parts, the lowest quote rarely delivers the lowest total cost. At Approved Sheet Metal in Hudson, NH, we field calls regularly from buyers switching vendors after quality or delivery problems. The pattern is consistent: what looked like savings on paper turned into rework costs, missed deadlines, and operational headaches that far exceeded any initial price advantage. We're not suggesting buyers ignore cost—that's unrealistic. But it’s also important to consider that precision sheet metal fabrication requires skilled employees, maintained equipment, quality control processes, and engineering support. Those capabilities represent overhead that gets built into each shop’s pricing. Shops quoting significantly below market rates are cutting costs somewhere, and buyers eventually pay the difference.Below, we'll break down the specific hidden costs that make cheap sheet metal parts expensive, and what to look for when evaluating fabrication partners beyond the bottom line of a quote.

Price matters in every purchasing decision. But when sourcing precision sheet metal parts, the lowest quote rarely delivers the lowest total cost. At Approved Sheet Metal in Hudson, NH, we field calls regularly from buyers switching vendors after quality or delivery problems. The pattern is consistent: what looked like savings on paper turned into rework costs, missed deadlines, and operational headaches that far exceeded any initial price advantage. We're not suggesting buyers ignore cost—that's unrealistic. But it’s also important to consider that precision sheet metal fabrication requires skilled employees, maintained equipment, quality control processes, and engineering support. Those capabilities represent overhead that gets built into each shop’s pricing. Shops quoting significantly below market rates are cutting costs somewhere, and buyers eventually pay the difference.Below, we'll break down the specific hidden costs that make cheap sheet metal parts expensive, and what to look for when evaluating fabrication partners beyond the bottom line of a quote.

Table of Contents

- 1 Top Risks of Choosing Cheap Sheet Metal Parts

- 2 1. Tight Tolerance Failures

- 3 2. Inconsistent Quality Control

- 4 3. Inferior Finishing and Appearance

- 5 4. Wrong or Substandard Materials

- 6 5. Lack of Material Traceability

- 7 6. Missed Deadlines

- 8 7. Unreliable Expedite Options

- 9 8. Hidden Supply Chain Delays

- 10 9. High Scrap and Rework Rates

- 11 10. Unexpected Engineering Costs

- 12 11. Poor Responsiveness and Service

- 13 12. Capacity and Scalability Limitations

- 14 How Quality Fabricators Prevent Hidden Costs

- 15 What to Look for When Vetting Sheet Metal Shops

- 16 Contact Approved Sheet Metal for Precision Fabrication

Top Risks of Choosing Cheap Sheet Metal Parts

| Risk | Impact on Your Business |

|---|---|

| Tolerance failures | Parts don’t fit together, assemblies stall, and rework or emergency remanufacturing wipes out initial savings |

| Missed deadlines | Production lines sit idle, product launches get delayed, and customers lose confidence in your reliability |

| Poor materials and traceability | Compliance requirements can’t be met, safety risks increase, and recalls or audit failures damage reputation |

| High scrap and rework rates | A large percentage of unusable parts means paying for replacements, losing labor time, and pushing back schedules |

| Lack of engineering and support | Preventable design flaws slip through, projects get stalled by unanswered questions, and hidden costs pile up |

1. Tight Tolerance Failures

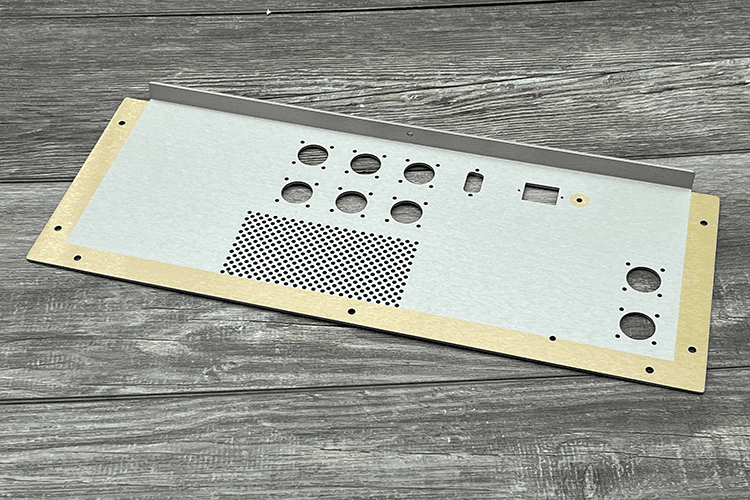

Precision sheet metal work often requires tolerances of ±0.005" or tighter. At that level of precision, even a deviation of a few thousandths of an inch can make a part unusable. Low-cost shops may lack the CNC punch presses, fiber lasers, or press brakes needed to hold these specifications consistently across production runs.

The first sample might look fine, but repeatability is the real test. Without proper calibration, skilled operators, and process control, precision drifts. Once parts fall out of spec, assemblies don’t fit, production schedules slip, and the scramble for emergency rework and expedited shipping quickly erases any savings.

For precision work, there’s no such thing as “close enough.” A part either meets spec or it doesn’t.

2. Inconsistent Quality Control

Quality control requires time, trained inspectors, and documented processes. Lower-priced shops often cut corners here because inspection adds cost without adding apparent value to the part itself.

The result is part-to-part variation. One batch of sheet metal brackets fits perfectly, while the next batch falls out of spec on critical dimensions. For industries like aerospace, medical devices, and electronics, this inconsistency creates serious problems such as failed assemblies, compliance issues, or field failures.

Beyond the immediate rework costs, inconsistent quality creates additional hidden expenses:

- Teams waste time sorting good parts from bad

- Buyers implement an extra inspection to catch defects the supplier missed

- Engineering resources get consumed investigating why assemblies suddenly don't fit

When defective parts reach end customers, the costs multiply through warranty claims and damaged reputation.

3. Inferior Finishing and Appearance

Deburring, grain direction, anodizing, and powder coating quality separate professional sheet metal work from sloppy fabrication. Lower-priced suppliers often cut corners on these finishing steps because they're time-consuming and add cost.

The consequences show up immediately:

- Parts arrive with rough edges that interfere with assembly or create safety concerns

- Powder coating appears uneven or poorly adhered

- Anodizing shows inconsistent color or thin coverage

- Grain direction gets ignored, leaving visible scratches and an unprofessional appearance.

For consumer-facing products, poor finishing undermines design intent and brand perception. For trade show samples or prototypes being shown to investors, subpar appearance can damage credibility before anyone evaluates actual performance. Even for internal assemblies, burrs and rough edges slow down production and create handling issues.

4. Wrong or Substandard Materials

Material costs represent a significant portion of sheet metal fabrication pricing. Some low-cost suppliers reduce quotes by substituting cheaper alloys or sourcing uncertified stock. So while the specified material might be 5052 aluminum, what arrives could be a lower-grade alternative.

At first glance, the parts may look fine. The real problems appear later when components fail under load, corrosion spreads faster than expected, or welding doesn’t behave as engineers planned. By the time those issues surface, tooling is paid for, assemblies are complete, and field installations may already be in place. What looked like savings has now created expensive failures.

5. Lack of Material Traceability

Material Test Reports (MTRs) and mill certifications aren't optional paperwork in aerospace, defense, and medical industries. These legally-required documents prove that the material used in fabrication matches specifications and comes from certified sources.

Lower-cost shops may skip proper documentation to reduce administrative overhead. They might not track which material lot went into which production run, or they can't provide mill certs proving the material's origin and composition. Some simply don't understand the compliance requirements their customers face.

The problem surfaces when an issue appears. If a single part fails and you need to identify which batch might be affected, incomplete traceability means you can't isolate the problem. Instead of replacing a specific lot, you may need to recall entire production runs. Auditors flag missing documentation, customers require proof you can't provide, and what started as a material question becomes a compliance failure that halts production and damages business relationships.

Shops that can't provide complete documentation create risk that responsible buyers can't afford to take.

6. Missed Deadlines

Shops focused on winning business with low prices often underquote lead times and overbook capacity. And by the time buyers realize parts won't arrive on schedule, they're already committed and left scrambling for alternatives.

The impact depends on what the parts are for:

- Assembly lines sit idle waiting for components

- Startups miss product launch dates

- R&D teams can't make trade show deadlines with sample parts

- Equipment stays down longer than planned because replacement brackets or panels haven't arrived

In our experience, customers switch vendors most often because of lead time problems and quality issues—not because they're trying to save money. Once you've dealt with missed deadlines that cost you real money or real opportunities, the cheapest quote stops looking like a bargain.

7. Unreliable Expedite Options

Whether it's due to equipment breakdown, engineering change, or an unexpected ordering spike, there will be situations when you don't just need parts—you need them now.

It's not uncommon for low-cost shops to turn down these requests, as it can be difficult for them to accommodate rush work orders without a massive disruption to their schedule. Or if they do agree to it, they'll tack on a premium rate that erases any savings from the original quote.

The real cost here isn't just the expedite fee, it's what happens when they agree to an order they can't realistically fulfill. Once it becomes evident that the shop can't deliver on the tight timeline you've requested, you'll be forced to find alternatives mid-project. The no-win choice is often to pay even higher emergency rates elsewhere or to watch deadlines slip by because there are no good options available.

Shops like Approved Sheet Metal that maintain capacity flexibility and have experience with urgent work provide value that isn't visible on the initial quote comparison.

8. Hidden Supply Chain Delays

If you focus only on the low-cost quote, offshore manufacturing can look like a bargain. But those savings often disappear once extended lead times, customs delays, and shipping uncertainties enter the picture.

Communication across time zones can also slow down problem resolution. A question that could be answered within an hour at a domestic shop might take a day or more when waiting for an overseas supplier. On top of that, tariffs and duties can change quickly, which affects the total costs once shipping and fees are included. And if parts arrive damaged or incorrect, returning them for rework can add weeks to an already long timeline.

Especially for projects with tight schedules, or where responsive communication is a must-have, offshore sourcing trades lower part costs for higher project risk. Yes, domestic fabricators often charge more per part, but that premium buys predictable transit times, easier communication, and the ability to address issues quickly when they arise.

9. High Scrap and Rework Rates

Process control takes investment. Shops need calibrated equipment, trained operators, documented procedures, and quality checkpoints throughout fabrication. Lower-priced suppliers often cut these costs, which shows up as higher scrap rates.

If a significant percentage of parts arrive out of spec or unusable, you're effectively paying twice—once for the original order and again for replacements or rework.

Beyond the direct material costs, high scrap rates create operational problems:

- Teams waste time sorting through shipments to identify good parts

- Engineering time gets consumed investigating why parts don't meet spec

- Assembly schedules get pushed back waiting for replacement components

These hidden labor costs often exceed the cost of the scrapped parts themselves.

10. Unexpected Engineering Costs

Shops without strong engineering capabilities will fabricate exactly what's on the drawing—even if the design has problems. They won't suggest modifications that could reduce cost, improve manufacturability, or prevent assembly issues down the line.

The result is preventable mistakes that get built into parts:

- A bend radius that's too tight for the material thickness

- Fastener holes positioned where they'll interfere with forming operations

- Features that require expensive secondary operations when a design tweak could eliminate them entirely.

By the time these issues surface, you've already paid for parts that could have been built better.

11. Poor Responsiveness and Service

Low-cost suppliers often operate with minimal staff. When you need an answer about a design detail or want a delivery update, getting a response can take days. There's nobody dedicated to managing customer accounts or answering technical questions promptly.

This slows everything down. Your team can't finalize designs without clarification on how features will be fabricated, you can't plan assembly schedules without reliable delivery information, and issues that could be resolved with a quick conversation drag on because nobody's available to discuss them.

Shops that staff customer service and engineering support cost more to operate, which gets reflected in pricing. But when responsiveness matters, and in most manufacturing environments it does, that overhead delivers value.

12. Capacity and Scalability Limitations

A shop that works well for your current needs may not be able to grow with you. Small, low-cost suppliers often lack the equipment, staff, or systems to handle increased volume when your production scales up.

This creates a difficult choice. Stick with a vendor who can't meet your growing demand and risk delivery problems, or switch to a new supplier and lose the process knowledge and relationships you've built. Changing fabricators mid-production means new learning curves, potential quality inconsistencies, and the time investment of onboarding a new partner.

When evaluating sheet metal shops, ask about their capacity and long-term goals. Are they set up for the type and volume of work you'll need six months or a year from now? Understanding a shop's capabilities and growth plans helps avoid the disruption of switching vendors when your needs outgrow their capacity.

How Quality Fabricators Prevent Hidden Costs

At Approved Sheet Metal, we understand that price matters. But we also know that the cheapest quote rarely delivers the lowest total cost. Here's how we help customers evaluate options and avoid the hidden expenses that make cheap parts expensive:

- Honest conversations before quoting: We'll tell you upfront if a project isn't a good fit for our capabilities. Recently, a prospect needed 200,000 production parts. Rather than waste time on a quote, we explained that high-volume production isn't our specialty and pointed them toward better options. That saved everyone time and set clear expectations.

- Engineering support during quoting: We review designs for manufacturability and suggest modifications that could reduce cost or improve quality. Sometimes what looks like a higher quote actually delivers better value because the part is designed correctly from the start.

- Full material traceability: Every part comes with proper MTRs and mill certifications when required. We maintain complete documentation to protect customers in regulated industries.

- Industry certifications: Our ISO 9001:2015 certification and ITAR registration support the rigorous quality and compliance standards we apply across every project, regardless of size or industry.

- Realistic lead times and reliable delivery: We don't underquote turnaround times to win business. Our lead times reflect actual capacity, and we can often accommodate expedites without massive disruption.

- Responsive communication: Customers work with dedicated account managers and have direct access to engineering support when questions arise.

Our pricing reflects the overhead required to deliver these capabilities consistently. The customers we serve across the U.S. could find cheaper alternatives, but they choose Approved Sheet Metal because total cost of ownership matters more than the initial quote.

What to Look for When Vetting Sheet Metal Shops

In addition to comparing quotes, it’s important to look deeper into how shops operate:

- Visit the facility if possible. You'll see immediately whether equipment is well-maintained, the shop is organized, and operations look professional. Some buyers decide to pay more after touring a facility because they can see where their money goes.

- Ask about recent investments. Shops that continuously invest in new equipment, software, and training demonstrate commitment to capability improvement. Price-driven shops typically defer these investments to keep costs down.

- Understand their customer base and capacity. Is the shop chronically overbooked? Do they have diverse customers across industries, or are they dependent on one or two large clients? A stable, diverse customer base suggests reliability.

- Talk to the owners. What are their goals for the business? Are they focused on growth and capability, or just keeping costs low? Understanding their priorities helps predict how they'll handle your work.

- Request material certifications upfront. If your application requires MTRs or specific material grades, verify the shop can provide proper documentation before placing an order.

- Check their engineering capabilities. Can they provide design-for-manufacturability feedback? Do they have experienced staff who can answer technical questions?

For industries like aerospace, defense, and medical devices where compliance and traceability are mandatory, these evaluation steps aren't optional. The risks of working with an unqualified supplier are too high regardless of the price difference. Even for less regulated applications, vetting fabrication partners thoroughly protects you from costly surprises.

Contact Approved Sheet Metal for Precision Fabrication

Cheap sheet metal parts aren't a bargain when hidden costs exceed initial savings. Tolerance failures, quality inconsistencies, missed deadlines, and lack of engineering support create expenses that show up after you've committed to a supplier.

Approved Sheet Metal's pricing reflects the investment required to deliver precision parts consistently: skilled employees, maintained equipment, quality processes, engineering support, and reliable capacity. We work with customers from prototype through production, providing the responsiveness and expertise that keeps projects on schedule and on spec.

Ready to discuss your sheet metal fabrication needs? Contact Approved Sheet Metal in Hudson, NH to learn how our precision fabrication capabilities help buyers avoid costly surprises.