Raw Sheet Metal Finish Standards

Not sure what finish makes sense for your project? Read our blog "What Finish Does My Precision Sheet Metal Part Need?" and "Surface Finish Considerations for Sheet Metal Fabricated Parts"

Class A

Class B-1

Class B-2

Class B-3

Class C

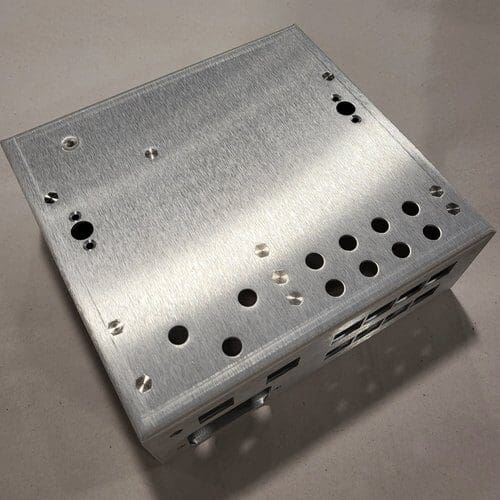

CLASS A:

Description: Cosmetic finish. No surface imperfections are acceptable. Good for external facing parts, medical devices, food-grade products etc.

Process: Light grain finish using either a timesaver or stroke sander. All surface imperfections to be removed and parts to be layered in paper to protect the surface. No press brake marks are acceptable.

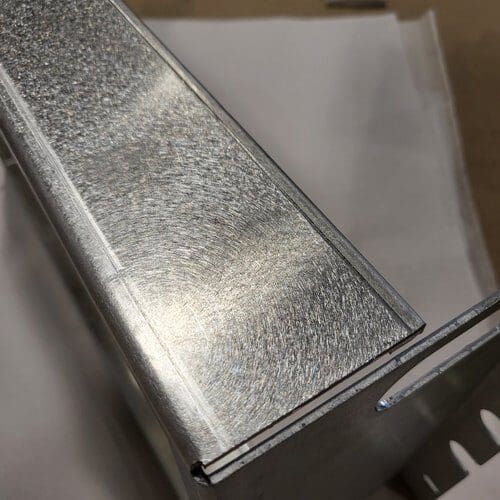

CLASS B:

Description: Standard FInish class, broken into three categories. Non-Cosmetic. Surface imperfections are acceptable and will not be removed. Press brake marks are acceptable. Parts that are plated will fall into this class most often.

Process:

B-1: Standard Timesaved Finish - Parts will have a light grain linear finish and sharp edges removed

B-2: DA or Orbital Sand Finish - Parts will have an orbital or nonlinear finish and sharp edges removed

B-3: Tumble Finish - Reserved for small parts under the limit of our timesaver. Parts will be put into a vibratory tumbler machine have a uniform, smooth, nonlinear finish.

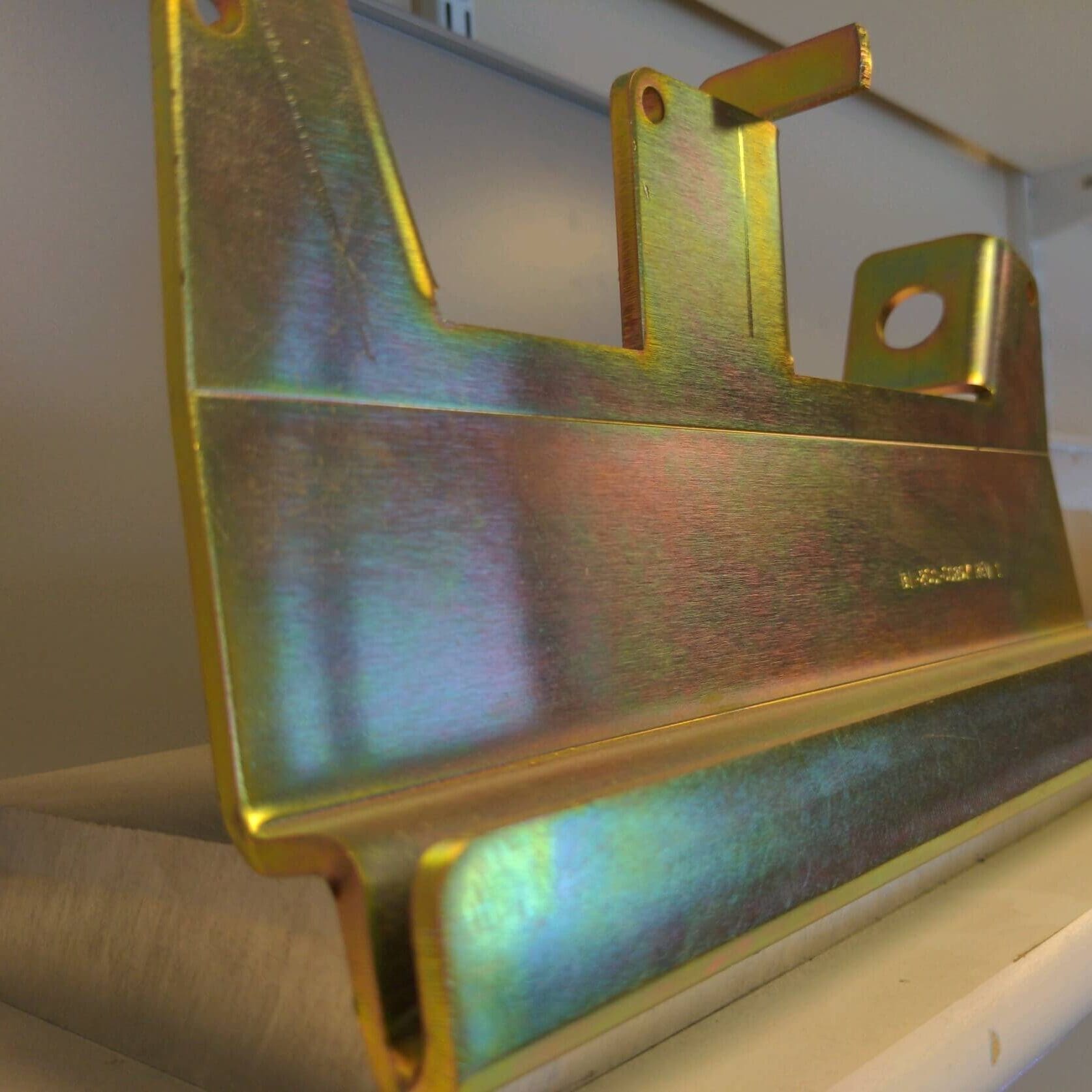

CLASS C:

Description: Mill finish

Process: Edge break only. No timesave or DA sanding. Press brake are marks acceptable. Parts will have sharp edges removed only. Our default class for painted parts.

Sheet Metal Powder Coating & Plating

We also have strong relationships with local platers and powder coaters so we can get parts completed in just days. We finish sheet metal parts in prototype and low-volume production quantities. In addition to sheet metal finishing, other capabilities that Approved Sheet Metal has extensive experience in include:

Frequently Asked Questions (FAQS)

What is your lead time for finished sheet metal fabricated parts?

Standard ship for finished sheet metal parts is 10-14 days, with expedites available!

What types of finishing do you offer?

Powder Coating, Silk-Screening, Wet Paint, Color Anodize, Chromate and more.

What considerations should I think about when designing parts?

There are ways to design parts, and specific features, that will help reduce back-and-forth and ensure that you get what you need out of your part. Take a look at our Sheet Metal Design for Manufacturing eBook to see best practices - See the eBook