Last updated on July 14th, 2025 at 09:41 am

Shorter lead times. Lower costs. A streamlined experience. These are all factors product developers prioritize when they need sheet metal parts.

Here, we explore five best practices to keep in mind when you’re working with Approved Sheet Metal or any other sheet metal shop.

Table of Contents

- 1 1. Send Solid-Body 3D Models

- 2 2. Follow Minimum Bend and Flange Length Guidelines

- 3 3. Communicate Your Exact Requirements—All of Them!

- 4 4. Discuss Material Options

- 5 Material Selection Guidance Beyond Aluminum

- 6 5. Get Familiar with Sheet Metal Tolerances vs. Machining Tolerances

- 7 Sheet Metal Design for Manufacturing

- 8 Partnering with a Sheet Metal Shop FAQ

- 8.0.1 Why is it essential to send Solid-Body 3D Models for sheet metal fabrication?

- 8.0.2 What issues commonly arise when part designs don't adhere to bend and flange length guidelines in precision metal fabrication?

- 8.0.3 How important is comprehensive communication about part requirements in precision metal fabrication?

- 8.0.4 Why is discussing material options vital in sheet metal fabrication?

- 8.0.5 What's the key difference between sheet metal tolerances and machining tolerances, and why is it important to understand?

1. Send Solid-Body 3D Models

For us to properly unfold and work with your 3D model, it must have a solid body. If your 3D model includes surface imports, it can’t be considered a solid body, and it may be impossible to program the part so it can hit the shop floor.

When our sheet metal shop receives a 3D model with surface imports, there are two possible next steps:

- You can convert your file’s surface import to a solid body model by knitting and thickening the part, then resend your file.

- Our team can add engineering time to your PO and handle the conversion ourselves.

Converting a surface import to a solid body model is often a simple fix. But if your part includes complex geometries, the process can be quite time-consuming. The conversion may also cause certain post-fabrication features to vanish from a model, such as countersinks, machined features, or threaded holes.

You’ll enjoy a smoother precision metal fabrication process if you send us a solid body model from the start.

2. Follow Minimum Bend and Flange Length Guidelines

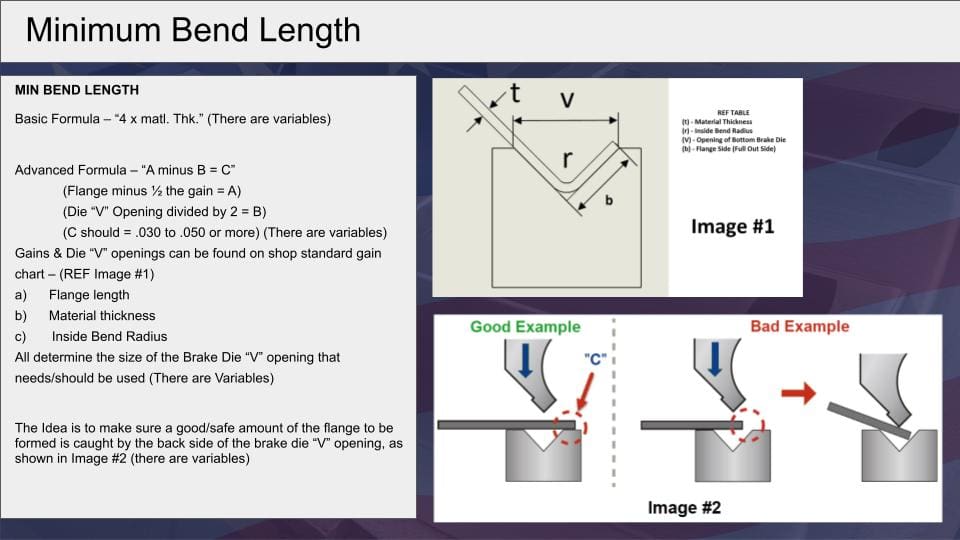

The most common issues we encounter involve part designs that don’t adhere to our guidelines for bend minimums and flange lengths. These calculations are critical in precision metal fabrication. Fail to follow them, and your part may need additional services, such as machining or custom tooling—or our sheet metal shop may be forced to no-quote the job altogether!

When dealing with improperly calculated flange lengths, we may need to extend the feature and then machine it to the desired length after forming, adding cost and lead time to your project. With certain material times and thicknesses, we’ll have no choice but to outsource the part for machining, further impacting your cost and lead time.

3. Communicate Your Exact Requirements—All of Them!

In precision metal fabrication, there is no such thing as too much information! The more details you provide about your part and its application, the better equipped our sheet metal shop will be to quickly and cost-effectively fabricate it.

Comprehensive callouts typically include these details, among many others:

- Material type and size

- Wall thickness

- Bend radii

- Tolerances

- Hole orientation

- Slot orientation

- Bend allowance

- Bend deduction

- Bend reliefs

- Manufacturing process

- Fabrication process

- Finishing process

4. Discuss Material Options

Material selection plays a crucial role in the success of a sheet metal project, and ASM can help you select the best material for your application.

Even two seemingly identical materials can offer dramatically different quality, durability, formability, strength, corrosion resistance, and more. Two such materials are aluminum alloys 6061-T6 and 5052-H32.

As we explain in this 6061-T6 and 5052-H32 comparison video, T6 aluminum is a popular choice among precision metal fabrication customers, but it’s prone to cracking and breaking during the fabrication process. We advise most customers to swap their T6 selection for 5051-H32 aluminum, which is significantly more cooperative during forming and bending.

Our sheet metal shop is here to help you get the best parts possible, so never hesitate to discuss solutions for improving your parts!

Material Selection Guidance Beyond Aluminum

While aluminum is a popular choice for many sheet metal projects due to its lightweight and corrosion resistance, it’s not the only material option—nor always the best one. Selecting the right material is critical for meeting your project’s performance, cost, and manufacturability requirements. Here’s a quick guide to some common alternatives and key considerations for each:

1. Stainless Steel

Stainless steel is prized for its excellent corrosion resistance, strength, and aesthetic finish. It’s a great choice for applications requiring durability in harsh environments, such as outdoor equipment, medical devices, or food processing. However, it tends to be heavier and more expensive than aluminum, and some grades (like 304 or 316) may require specialized welding techniques.

Key considerations:

- Heavier than aluminum—may impact overall product weight

- Requires careful selection of alloy grade for corrosion resistance

- Can be more difficult to form; tighter bend radii may increase risk of cracking

2. Carbon Steel (Cold-Rolled or Hot-Rolled)

Carbon steel offers high strength at a lower cost and is widely used for industrial and structural components. It’s suitable for indoor applications or parts that will be painted or powder coated for corrosion protection. Compared to stainless, carbon steel is easier to weld and form but will rust if left uncoated.

Key considerations:

- Less corrosion-resistant unless coated

- Typically more cost-effective than stainless steel

- Good for structural parts that require toughness and strength

3. Galvanized and Galvannealed Steel

Galvanized steel is coated with a thin layer of zinc, providing excellent corrosion resistance in wet or outdoor environments. Galvannealed steel is similar but also heat-treated to improve coating adhesion and weldability. Both are common in automotive, HVAC, and construction industries where durability and weather resistance are needed without the higher cost of stainless steel.

Key considerations:

- Zinc coating improves corrosion resistance

- Welding requires special techniques to avoid coating damage

- Surface preparation is important for finishing

4. Copper and Copper Alloys

Copper is ideal for applications requiring excellent electrical and thermal conductivity, such as grounding components or heat exchangers. It’s softer and more ductile than steel or aluminum, making it easier to form but less suitable for high-load structural parts. Copper alloys like brass or bronze offer improved strength and machinability.

Key considerations:

- Superior conductivity and corrosion resistance

- Generally higher material cost

- Softer material—may require special handling to avoid deformation

Making the Right Choice

Material selection affects everything from fabrication method and lead time to part performance and cost. It’s important to balance:

- Mechanical properties: Strength, ductility, fatigue resistance

- Environmental factors: Corrosion, temperature exposure

- Fabrication compatibility: Weldability, formability, surface finish options

- Budget and lead time: Material availability and cost impacts

Our experienced team at Approved Sheet Metal is happy to discuss your project requirements and recommend the best material solution that balances performance, cost, and manufacturability. Early collaboration ensures your design is optimized for both function and production efficiency.

5. Get Familiar with Sheet Metal Tolerances vs. Machining Tolerances

If you weren’t aware that sheet metal tolerances are more complicated than machining tolerances, you’re not alone; many engineers don’t learn about these differences in school.

The sheet metal fabrication process generally yields looser tolerances. Important factors to consider are material thickness and bend radius. Sometimes, achieving tight tolerances with forming alone is impossible, meaning additional processes will be required.

From the start, inform our sheet metal shop of your part’s tolerance requirements, and we’ll ensure you receive an accurate quote that reflects all the steps necessary to get you what you need.

Ready to get started? Request a quote today.

Need more design tips? Check out our Top 6 Custom Sheet Metal Design Blog Posts of 2022