Last updated on February 4th, 2026 at 09:14 am

Most sheet metal shops don’t have prototype fabrication experts on staff, and if they do, they are typically not engineers. Approved Sheet Metal has an intentionally high number of engineers on our team, which helps us troubleshoot designs from the customer’s perspective to deliver optimal parts.

With over 100 years of combined sheet metal fabrication experience, our engineers have encountered—and overcome—the same challenges our customers face. Our team can communicate the best way to proceed with a sheet metal design and catch potential issues before those issues become BIG problems.

With a wealth of professional experience in areas such as working with special hinges, choosing hardware replacements, and selecting the right material for sheet metal prototypes, the Approved Sheet Metal team can suggest adjustments that result in better parts and often reduce costs and lead time.

Table of Contents

- 1 How Our Engineers Optimize Sheet Metal Prototypes

- 2 Common Design Challenges Our Engineers Resolve

- 3 CAD File Preparation Guidelines: Set Your Project Up for Success

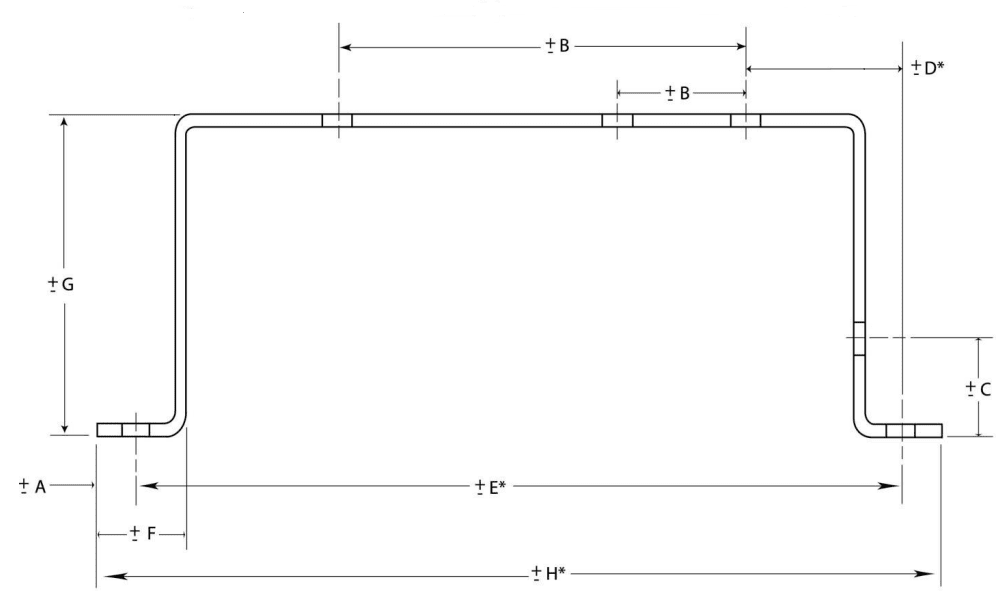

- 4 Recommended Default Sheet Metal Tolerances

- 5 Sheet Metal Design Engineering FAQ

- 5.0.1 What sets Approved Sheet Metal's engineering team apart in sheet metal prototype fabrication?

- 5.0.2 How do engineers at Approved Sheet Metal optimize sheet metal prototypes?

- 5.0.3 What common design challenges do Approved Sheet Metal engineers resolve in sheet metal prototype fabrication?

- 5.0.4 How does the engineering expertise at Approved Sheet Metal address concerns related to part size and formability in prototypes?

- 5.0.5 What advantage does partnering with Approved Sheet Metal for prototype fabrication offer to customers?

How Our Engineers Optimize Sheet Metal Prototypes

At Approved Sheet Metal, we run seven fabrication operations. All of our programmers are trained to run each of these operations, and cross-training distinguishes us from our competitors. We’ve achieved this versatility in part by creating a workflow that’s informed by engineering expertise at every level.

Creating high-level work instructions

Our engineers’ role in prototype fabrication begins during quoting when they consult with customers to determine part specifications and suggest potential design adjustments.

Next, they draft comprehensive work instructions that stay with the part throughout its workflow, making it crystal clear which steps should be executed during each operation.

Providing proactive feedback and smart solutions

Our engineers are happy to work with product developers in the early stages of prototype development to catch potential issues before they materialize. We welcome the opportunity to answer questions upfront about the optimal material type, hardware options, tolerance requirements, or any other concern to save you from headaches down the road.

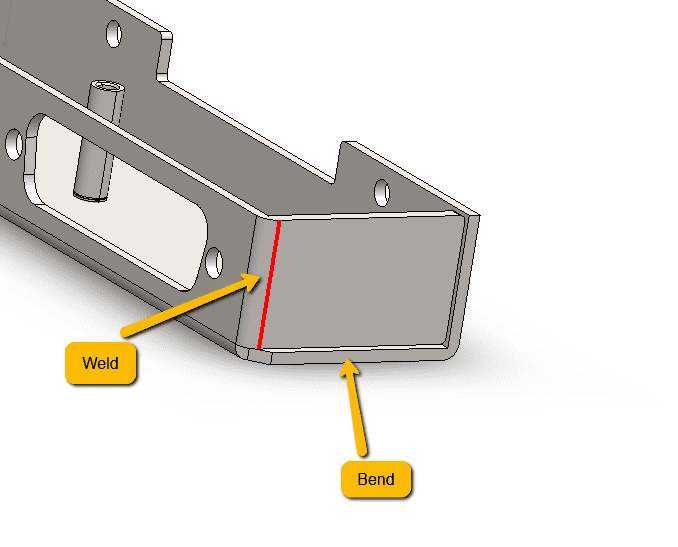

We often field questions about welding—in particular, whether a part can be welded, what kind of welding would be best, or whether a fastening method (e.g., riveting or bolting) would provide a better solution. By suggesting alternatives to welding where appropriate, our engineers can save you a tremendous amount of time and money when your part moves into production.

It’s not always possible to make such adjustments on the front end, however, as your prototype design may be fixed by the time you bring it to our shop. In that case, our engineers will help you troubleshoot any problems that arise now so they aren’t replicated during production.

Common Design Challenges Our Engineers Resolve

Here are some of the top sheet metal prototype design challenges we resolve using in-house engineering knowledge.

Hardware issues

- Incompatibility between hardware and material type (e.g., steel hardware for stainless steel parts)

- Special-order hardware with order minimums and long lead times

Unattainable or highly restrictive specifications

- Parts designed with internal bend radii that are impossible to achieve

- Extremely tight tolerance specifications that require custom tooling or pose potential assembly challenges

Formability concerns

- Flanges that are too short to be functional

- Features that are too close to bends

- Parts that require bend reliefs

- Features that cannot be formed with standard tooling

Weldability concerns

- Joins that will require too much weld, leading to part deformation

- Weld types that are ill-suited for a part (e.g., spot vs. tack)

Part size concerns

Designs for a large single part that would function better as multiple parts joined or fastened together

Our team’s strong engineering acumen enables us to tackle sheet metal prototypes from the vantage point of people who have designed them.

CAD File Preparation Guidelines: Set Your Project Up for Success

One of the most impactful ways to reduce lead time and avoid rework is by submitting clean, fabrication-ready CAD files. At Approved Sheet Metal, we often receive files that require clarification or rework before production can begin. Here’s how to ensure your CAD models are optimized for fast, efficient quoting and fabrication:

- Submit native 3D files and 2D drawings: We prefer receiving original 3D CAD files (like SolidWorks

.SLDPRT, STEP, or IGES formats) along with 2D PDF prints that clearly define tolerances, hole callouts, finishes, and critical dimensions. The 3D model drives flat pattern development, while the PDF communicates design intent. - Flatten sheet metal parts properly: Ensure your sheet metal parts are modeled using the sheet metal tools in your CAD software, not just as solids. This makes it possible to generate accurate flat patterns for quoting and nesting. Avoid submitting zero-thickness geometry or models with features that can’t unfold.

- Specify critical dimensions and tolerances clearly: Indicate which features are critical to function and where tighter tolerances are needed. Unnecessarily tight tolerances on every feature drive up cost and slow production. If in doubt, ask us—we’ll help you find the balance between precision and manufacturability.

- Avoid cosmetic-only geometry: Remove logos, text, or aesthetic fillets/chamfers from early-stage prototype files unless they serve a functional purpose. These features can always be added later in the design cycle.

- Use consistent units and materials: Clearly label units (inches vs. mm) and include material type and gauge. If you’re unsure which material best suits your needs, our engineers can recommend options that reduce cost or improve performance.

- Include hardware callouts with manufacturer part numbers: If your design includes PEMs or fasteners, list the exact part number and spec in your drawing notes or a BOM. When a hardware spec is missing or unclear, it can delay quoting and require time-consuming back-and-forth.

Following these CAD prep best practices ensures fewer delays, smoother fabrication, and faster delivery of your parts.

When you partner with Approved Sheet Metal for prototype fabrication, you’ll have peace of mind knowing you’re working with team members who have been in your shoes and know how to set you up for success.