Last updated on January 26th, 2026 at 02:48 pm

Sheet metal fabrication is a highly versatile manufacturing process used to produce durable parts ranging from early prototypes to full production runs. For mechanical engineers, small design decisions made early in CAD can have a significant impact on cost, lead time, and manufacturability.

In this article, we outline five practical, shop proven tips to help you optimize your sheet metal designs for efficiency and cost without sacrificing quality, based on real world fabrication experience at Approved Sheet Metal.

Table of Contents

- 1 1. Material Selection Matters

- 2 2. Design with Standard Gauges in Mind

- 3 3. Embrace Simplicity in Bends

- 4 4. Strategically Manage Tolerances

- 5 5. Ensure Consistent Bend Orientation

- 6 Recommended Default Sheet Metal Tolerances

- 6.1 Optimizing Sheet Metal Fab Design FAQ

- 6.1.1 Why is material selection important in sheet metal fabrication?

- 6.1.2 What are the benefits of designing with standard gauges in mind?

- 6.1.3 How can simplicity in bends reduce fabrication costs?

- 6.1.4 Why is it important to strategically manage tolerances in sheet metal design?

- 6.1.5 How does maintaining consistent bend orientation benefit the fabrication process?

- 6.1 Optimizing Sheet Metal Fab Design FAQ

1. Material Selection Matters

Material choice has a direct impact on part cost, lead time, and manufacturability. Selecting the right material early can help minimize waste, reduce processing steps, and avoid sourcing delays. When prototyping, consider using readily available materials such as Aluminum 5052 instead of higher cost options like 304 stainless steel when performance requirements allow.

Availability also plays an important role. Choosing materials that are commonly stocked by your fabricator can significantly shorten lead times. Review Approved Sheet Metal’s full list of available materials to make informed decisions based on your project requirements.

Sheet Metal Material Deep Dive Articles:

- Choose the Right Material Thickness for Your Custom Metal Fabrication

- 3 Ways to Optimize Your Sheet Metal Material

- Choose the Right Material to Speed Up Lead Time for Precision Sheet Metal Parts

- Aluminum Smackdown: 5052-H32 Takes on 6061-T6 for Custom Sheet Metal Fabrication Superiority

- 4 Things You Didn’t Know about Aluminum

- 5052, 6061, 7075: ASM’s Guide to Sheet Metal Aluminum Grades

- 3 Things You Didn’t Know About Stainless Steel

- Galvanized vs. Galvannealed Steel: A Sheet Metal Comparison

2. Design with Standard Gauges in Mind

Designing around standard sheet metal gauges improves manufacturability and reduces sourcing challenges. Approved Sheet Metal can fabricate parts up to ¼ inch (6.35 mm) thick depending on part geometry. Thicker materials can limit achievable bend radii and increase forming difficulty.

Sticking to common gauges helps avoid custom sourcing, secondary processing, and tooling limitations that can increase both cost and lead time. Understanding your fabricator’s capabilities early helps streamline the design process.

3. Embrace Simplicity in Bends

Simple bend geometry is one of the most effective ways to control fabrication cost. Straightforward angled bends with an inside radius equal to or greater than the material thickness are easier to form consistently. Complex bend geometry, tight radii, or small bends on thick material often require additional setups and can introduce variation.

Whenever possible, keep bend radii consistent across a part. Mixed bend radii frequently require additional tooling changes or setups. Refer to Approved Sheet Metal’s Design Guide for best practices that support accurate and cost effective forming.

Sheet Metal Forming Deep Dive Articles:

- Are You Using the Right Bend Radius for Your Precision Sheet Metal Formed Part?

- The Best Metal Bending Solution for Sheet Metal Prototyping

- 5 Best Practices for Precision Sheet Metal Fabrication Drawings

- Use This Flange Formula for Sheet Metal Forming

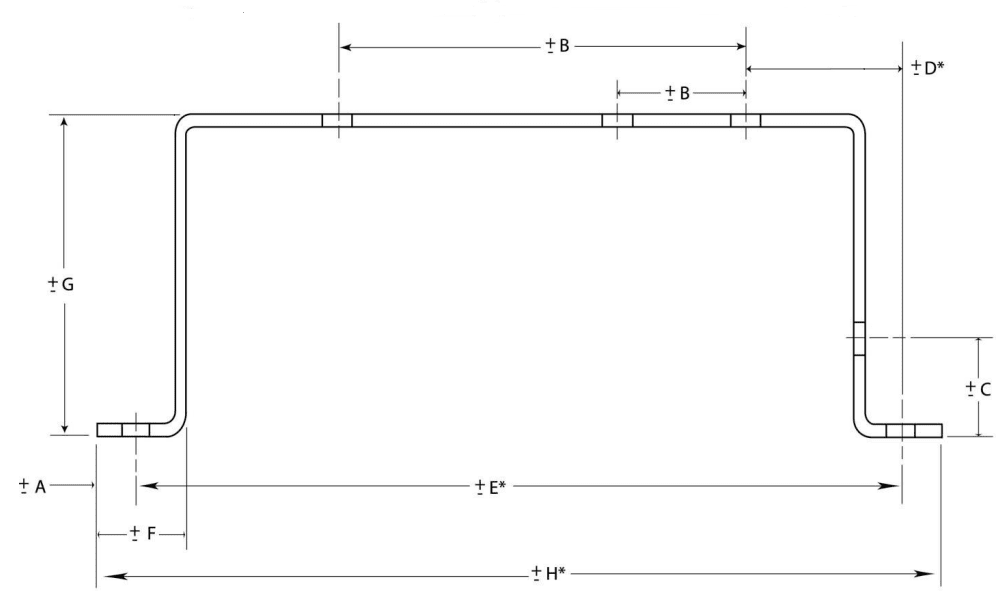

- Designing and Forming U-Shaped Sheet Metal Fabricated Parts

- The 3:1 Rule for Precision Sheet Metal Punch Forming

4. Strategically Manage Tolerances

Not every feature requires a tight tolerance. Each tolerance callout increases inspection time, quoting complexity, and overall part cost. Focus tolerance specifications only on features that directly impact fit, function, or assembly.

Over dimensioning features such as hole locations, radii, or formed edges can unnecessarily drive cost. Working with your fabricator to identify which dimensions are truly critical helps ensure parts meet requirements without added expense.

5. Ensure Consistent Bend Orientation

Consistent bend orientation allows parts to be formed with fewer reorientations on the press brake. This reduces handling time, improves repeatability, and lowers the risk of dimensional variation. Designing parts so bends occur in the same direction whenever possible leads to faster and more predictable fabrication.

For visual examples and forming fundamentals, explore Approved Sheet Metal’s

Sheet Metal Fab Forming Videos.