Last updated on February 4th, 2026 at 08:41 am

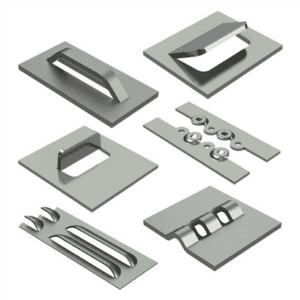

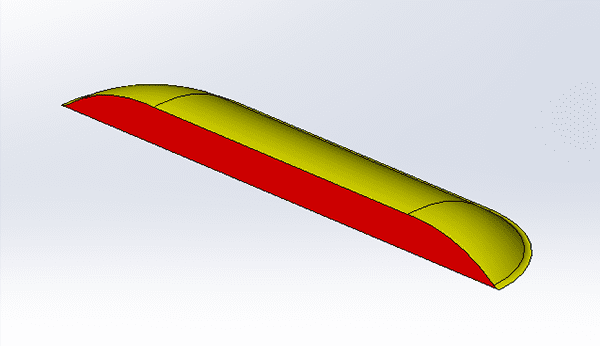

Punch forming is a highly efficient capability for adding formed features such as louvers and embossments to precision sheet metal parts.

The process involves sandwiching a piece of sheet metal between a punch and a die. Although it’s relatively straightforward, there is one design tip that can help you get your punched sheet metal prototypes as quickly as possible: following the 3:1 rule.

Table of Contents

- 1 Why the 3:1 Rule Exists: The Science Behind It

- 2 The 3:1 Rule for Sheet Metal Punching

- 3 What If You Can’t Follow the 3:1 Rule?

- 4 Sheet Metal CAD Tooling Library

- 5 The 3:1 Rule Sheet Metal Punch Forming FAQ

- 5.0.1 What is the 3:1 rule in sheet metal punching?

- 5.0.2 Why is it important to follow the 3:1 rule in sheet metal punching?

- 5.0.3 What should I do if I can't follow the 3:1 rule in sheet metal punching?

- 5.0.4 Can I perform a stamping operation with custom tooling if I need a specific feature that violates the 3:1 rule?

- 5.0.5 How can I revise the design to accommodate the 3:1 rule in sheet metal punching?

Why the 3:1 Rule Exists: The Science Behind It

The 3:1 rule isn't just a manufacturing guideline—it’s based on fundamental principles of material behavior, tool limitations, and sheet metal integrity. Understanding why this rule exists can help engineers design better parts while avoiding costly errors.

1. Material Properties & Metal Forming Limits

Sheet metal is relatively thin, meaning it has limited structural integrity when subjected to extreme deformation. When forming features like louvers and embossments, the material undergoes plastic deformation, where it stretches beyond its elastic limit to hold a new shape. However, if a feature is too tall (exceeding 3x the material thickness), several problems arise:

- Tearing & Cracking – The metal may stretch too thin and rupture at stress points.

- Springback – Excessive deformation increases the likelihood that the material will "snap back" after forming, causing inconsistency in dimensions.

- Wrinkling & Distortion – The unsupported height can create instability, leading to unpredictable warping.

2. Punch & Die Tooling Constraints

Punch presses are designed to work within controlled forming depths. The further a punch needs to travel into a die to create a feature, the more force is required. If a formed feature exceeds the 3:1 ratio:

- The punch may bottom out before achieving the intended shape.

- The tooling may experience excessive wear, leading to defects and shorter tool life.

- The sheet metal may jam in the die, causing production delays or damage to the part.

3. Maintaining Consistent Part Quality

Adhering to the 3:1 rule ensures that every part produced is consistent in size and shape. Deviating from this rule increases variability, making it harder to maintain tolerances.

- A punch press cycle is designed to create repeatable parts; exceeding recommended limits makes it difficult to achieve uniform results.

- Forming features that are too deep could lead to misalignment with mating parts in an assembly.

The 3:1 Rule for Sheet Metal Punching

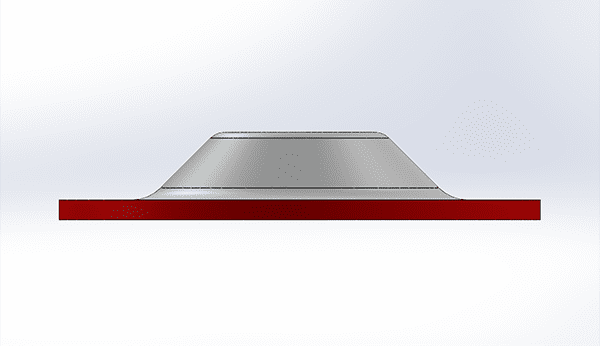

The 3:1 rule states that when designing a formed feature in a precision sheet metal part, the feature's height should be no more than 3x the material thickness above the material surface.

For example, if you have a part that measures 0.060" thick and you want to add a louver that's 0.375" high above the material surface, it just won't work. We can't run the part in the punch press when the features are too high because the punch isn’t designed to work with these dimensions. Instead, you’d want to make the louver 0.180” high, which is 3x the material thickness.

For example, if you have a part that measures 0.060" thick and you want to add a louver that's 0.375" high above the material surface, it just won't work. We can't run the part in the punch press when the features are too high because the punch isn’t designed to work with these dimensions. Instead, you’d want to make the louver 0.180” high, which is 3x the material thickness.

What If You Can’t Follow the 3:1 Rule?

Understandably, there are times when customers can’t easily follow the 3:1 rule, in which case there are two paths forward:

1. Performing a stamping operation with custom tooling

If you absolutely need a specific feature that violates the 3:1 rule, we can perform a stamping operation with custom tooling—though this approach will cost both time and money.

Custom tooling is expensive and can take weeks to arrive. In most cases, it’s hard for customers to justify spending thousands of dollars for this solution—especially for sheet metal prototypes.

2. Revising the design

A better option is usually to revise the design to achieve the required functionality while accommodating the 3:1 rule.

For example, louvers are used for various applications (e.g., downspouts, gutters, vents,

windows), and their primary function is simple: providing proper airflow. Some customers design louvers that are too high in an effort to maximize the airflow in a sheet metal prototype. We've seen engineers solve this issue by adding more louvers to the part and lowering the height of each one. This way, the customer meets airflow specifications, and we can make the part quickly using our punch press.

Customers may also decide to revise their designs slightly when embossments—features commonly used to maintain a specific distance between parts—violate the 3:1 rule. We might suggest spacers as a better alternative for your sheet metal prototype in those cases.

Whenever possible, Approved Sheet Metal will be proactive about recommending minor adjustments to make your life easier. We’ll contact you to talk through any potential concerns so that, no matter what, you get the exact parts you need.

Whether you’re looking for punch forming or other precision sheet metal fabrication services, our team is standing by to get started on your next project. Request a quote today!