Last updated on March 11th, 2025 at 09:01 am

At Approved Sheet Metal, we like to help our customers save time and money on custom metal fabrications whenever possible.

Today, we’ll detail some of the simplest actions you can take to optimize a piece of sheet metal and get the most bang for your buck.

Table of Contents

- 1 How to Get the Most Out of Sheet Metal Material

- 2 A note on Material Thickness, Bend Radii, and Tolerances

- 3 Recommended Default Sheet Metal Tolerances

- 4 Sheet Metal Material Optimization FAQ

- 4.0.1 How can I maximize the use of sheet metal material to save costs?

- 4.0.2 What's a smart strategy for optimizing sheet metal usage?

- 4.0.3 Can I request a custom sheet size if my part is smaller than standard dimensions?

- 4.0.4 How can I get the most out of same-day flat parts using sheet metal?

- 4.0.5 What should I consider when designing parts to fit on a single sheet?

How to Get the Most Out of Sheet Metal Material

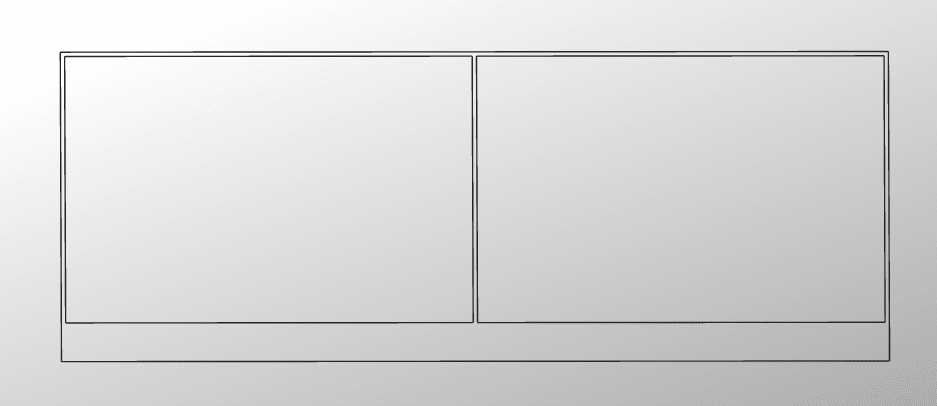

1. Fit two parts on a sheet instead of one.

We find that when engineers are aware of the standard sheet sizes available, they can frequently adjust part drawings to fit more than one part on a single sheet. So without further ado, here are the standard sheet sizes you can expect from Approved Sheet Metal:

- 48” x 48”

- 36” x 96”

- 48” x 96”

- 36” x 120”

- 48” x 120”

For same-day flat parts, 48” x 48” is the standard size. It’s possible to source sheets up to 60” x 120”, but you’ll pay a premium and probably add a few days to your lead time.

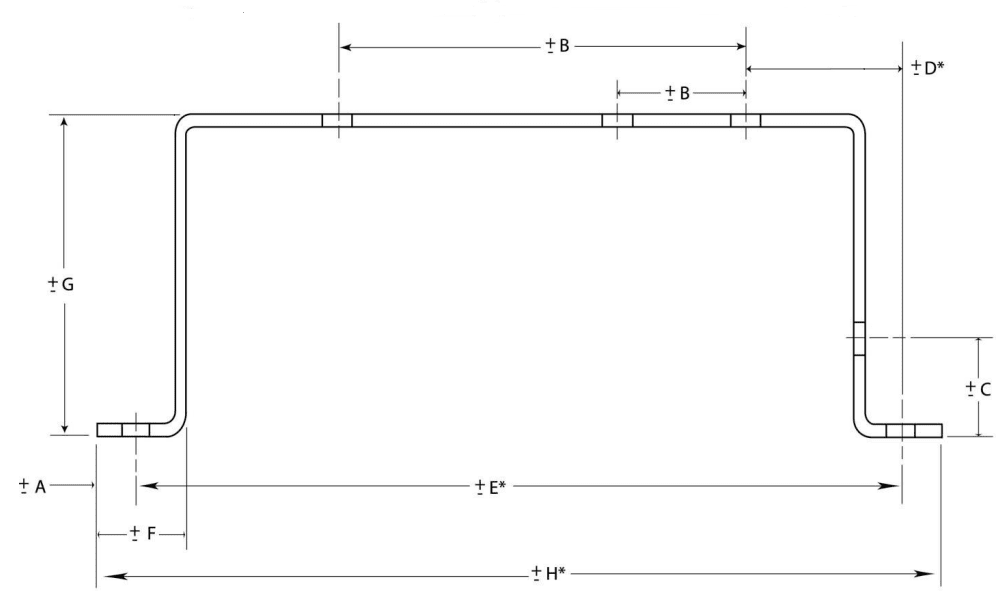

To reliably fit two parts onto one sheet, we advise customers to design flat patterns that leave ¼” to ½” of allowance around each part and keep in mind most blanking machines have an unusable dead zone of 1” - 4” in the Y direction or smaller size of the sheet. In other words, if you want to fit two parts on a 36” x 96” sheet, plan for each part to measure no more than

- 31” = 36” - dead zone - 2 times the part spacing X for the width

- 47.25” = (96” - 3 spaces * part space (.5”))/ 2 parts

The example below with a part size of 31” x 47.25”

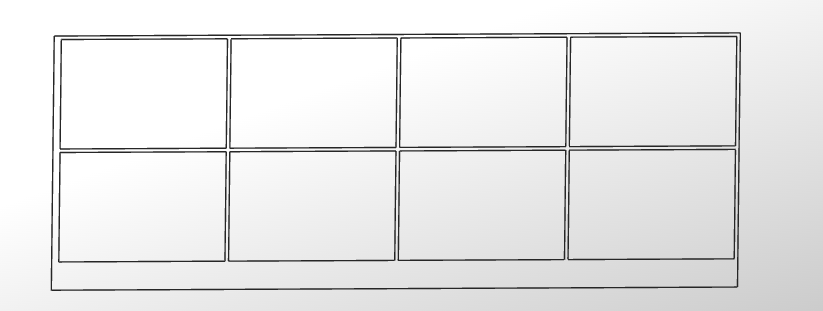

The example below with a part size of 15.5” x 23.25”

2. Pair a large part with a small part.

One of the best ways to optimize sheet metal material is to pair a large part with a small part when getting a quote for custom metal fabrications.

Once you know the standard sheet sizes available, you can determine how much material will be left over and get another part out of the remaining material that you’re already paying for.

3. Request a custom sheet in a smaller size.

Custom sizing is an option if your part is smaller than the standard sizes.

We recently sourced a 36” x 120” sheet for a customer who needed a 31.45” x 39.125 ” part. Had they gone with the standard 48” x 120” size, they would have wasted a substantial amount of material. Getting the smaller size ultimately ended up saving them money and reducing waste.

The right sheet metal shop will always go to bat for you to optimize your sheet metal material and find a sheet size that best fits your parts. But if you can make some of these changes or requests upfront, it expedites the whole process.

A note on Material Thickness, Bend Radii, and Tolerances

When optimizing sheet metal for fabrication, understanding thickness limitations and material properties is crucial. Different alloys behave differently during bending, which impacts bend radii, tolerances, and manufacturability.

1. Thickness Limitations

- Minimum Bendable Thickness: Thin sheets (e.g., 0.020”–0.063”) can be bent with tight radii but may be prone to warping or cracking if the bend radius is too small.

- Maximum Bendable Thickness: Thicker sheets (e.g., 0.250” and above) require larger bend radii to prevent excessive stress and potential cracking. Press brake tonnage also increases significantly for thicker materials.

2. Bend Radii by Material Type

Each metal type has different ductility, affecting the minimum bend radius:

- Aluminum (5052, 6061, etc.) – More prone to cracking, especially 6061, which has lower ductility. A typical bend radius should be at least 1.5x the material thickness for 6061, while 5052 can go as low as 1.0x thickness.

- Stainless Steel (304, 316, etc.) – Requires larger bend radii due to its higher strength. A safe rule is 1.5–2.0x the material thickness to avoid work-hardening and cracking.

- Cold-Rolled Steel (CRS) and Hot-Rolled Steel (HRS) – More forgiving in bending. A minimum bend radius of 1.0x thickness is generally safe, though high-carbon steels may require larger radii.

3. Tolerances and Springback Considerations

- Springback: Occurs when the material tries to return to its original shape after bending. Higher strength materials (stainless steel, high-carbon steels) will exhibit more springback, requiring adjustments in tooling and bend angles.

- Tighter tolerances require precision tooling, often involving air bending or bottoming to achieve consistent angles.

- Grain direction matters – Bending against the grain (perpendicular) reduces cracking risk, while bending with the grain increases the chance of fractures, especially in harder alloys.

By considering these material properties upfront, engineers can design parts that are more manufacturable, reduce scrap, and minimize costly rework. If unsure, consult with your fabricator to select the best material and bending approach for your project.

We’re happy to help customers find the right material for their part. Give us a shot on your next project and see for yourself how dedicated we are to saving you time and money.