Last updated on March 31st, 2025 at 10:22 am

Are you concerned that your sheet metal part can’t easily be fabricated in one piece? Some large parts are simply too big to fit on standard sheet metal fabrication equipment.

You’ve come to the right place! At Approved Sheet Metal, we routinely help our customers solve problems, including finding the best manufacturing solution for large part designs.

You’ve come to the right place! At Approved Sheet Metal, we routinely help our customers solve problems, including finding the best manufacturing solution for large part designs.

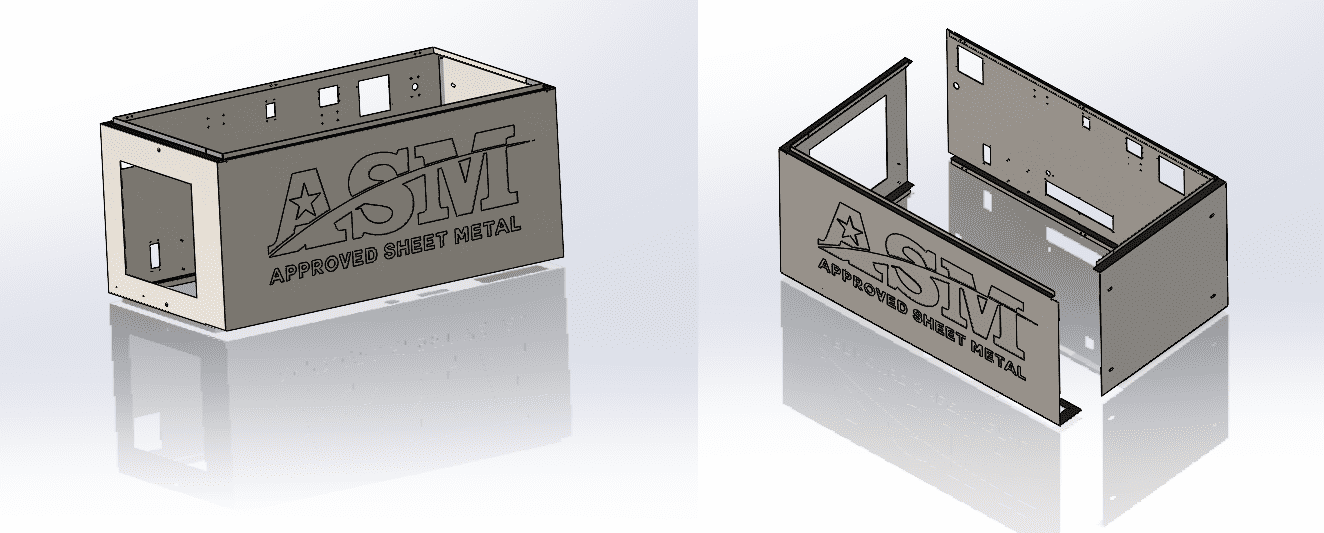

In most cases, we can fabricate the part in more than one piece and then weld or fasten the pieces together. We'll help you identify the best location on your part for this separation to occur. Our expertise in this area is important because it ensures the weld will be clean and efficient and that the finished part will retain its original functionality.

There are some cases in which separating a part and subsequently welding the pieces together is simply not an option. If necessary, we’ll help you modify your design so that it’s possible for us to fabricate the entire part in a single piece.

Keep reading to learn more about considerations for large part fabrication.

Table of Contents

- 1 Considerations for Fabricating Large Sheet Metal Parts

- 2 Fastening & Assembly Alternatives

- 3 Sheet Metal Design for Manufacturing

- 4 Large Sheet Metal Fabricated Part FAQ

- 4.0.1 What considerations should I keep in mind when fabricating large sheet metal parts?

- 4.0.2 Can all materials be welded together for large part fabrication?

- 4.0.3 How can I ensure my large sheet metal part can be fabricated in one piece, and what if design modification is not an option?

- 4.0.4 What are the size constraints for laser-cut parts and parts formed on the press brake at Approved Sheet Metal?

- 4.0.5 Can Approved Sheet Metal help with the fabrication of large parts that can't be made in one piece?

Considerations for Fabricating Large Sheet Metal Parts

Trying to determine the right approach for your large part? Here are a few factors to consider:

- Type of material

Welding is only an option for certain types of materials. For instance, aluminum isn't strong enough to withstand the forces applied to welded locations and still function as intended.

If necessary, we can help you find a suitable replacement metal that will allow your parts to be welded. Steel or stainless steel are both stronger than aluminum and hold up well under welding.

- Size constraints

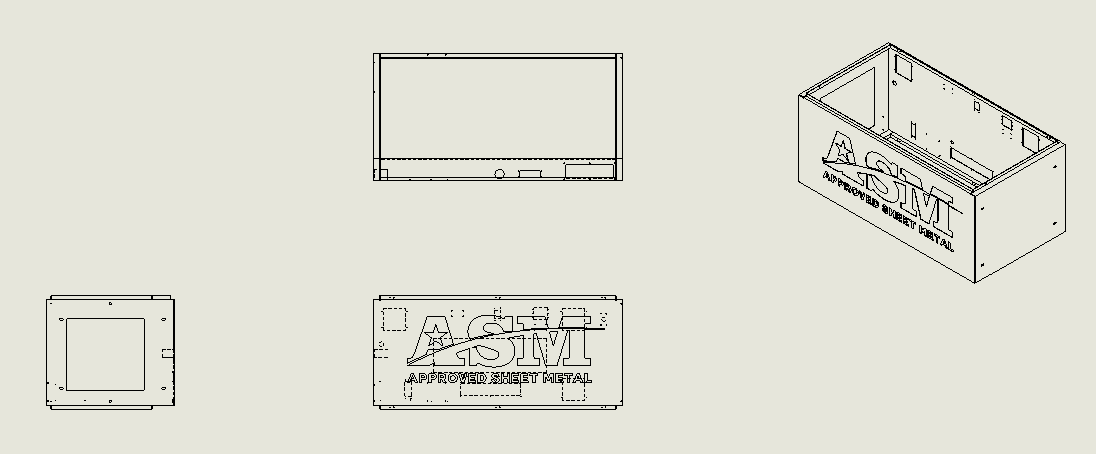

Our clearly defined size constraints will help you determine if your sheet metal part can be fabricated in one piece.

The maximum dimensions for laser cut parts are 120” by 60”. For parts that need to be formed on our press brake, the limiting dimension is length at a maximum of 80”.

- Forming restrictions

The shape and thickness of a sheet metal part are key factors that may result in potential forming restrictions.

If, for example, the part is designed in such a way that the tools collide with it or the features curve too sharply in a circular fashion, single-piece fabrication likely won’t be an option.

- Design flexibility

If modifying your part design isn’t a possibility, then fabricating it in two pieces may be the only solution. On the other hand, if you have some degree of flexibility in your design, you may be able to get your part fabricated in one piece after all.

Fastening & Assembly Alternatives

When welding isn't ideal for large sheet metal parts, alternative fastening methods can provide strong, reliable connections while reducing heat-related distortion and production costs. Choosing the right assembly method depends on material type, load conditions, and end-use requirements.

1. Bolted & Riveted Joints

For large sheet metal components, bolting and riveting offer a practical alternative to welding, particularly when disassembly or field repairs are necessary.

- Bolted Connections: Ideal for structural applications where parts must be periodically replaced or adjusted. Use flange joints or gussets to distribute stress.

- Riveting: Common in aerospace and automotive applications where vibration resistance is critical. Solid and blind rivets are excellent for thin-gauge sheet metal.

Tip: Use PEM® inserts, weld nuts, or self-locking fasteners to create strong, threaded connections without additional machining.

2. Clinching & Press-Fit Fasteners

For sheet metal parts that need strong, permanent connections without welding or screws, clinching is a highly effective option.

- Clinching mechanically deforms the metal, locking sheets together without additional hardware. It’s ideal for thin-gauge materials and corrosion-prone environments where welding might weaken the material.

- Press-fit fasteners, such as self-clinching studs or nuts, embed directly into the sheet metal, reducing the need for secondary machining and improving assembly efficiency.

3. Adhesive Bonding

Advanced structural adhesives provide a seamless, high-strength bond between large sheet metal components.

- Reduces stress concentrations by distributing loads across a larger area.

- Works well with dissimilar metals, eliminating galvanic corrosion risks.

- Ideal for aerospace and automotive applications where lightweight, vibration-resistant assemblies are required.

Tip: Use adhesives with mechanical fasteners for a hybrid approach that improves both structural integrity and manufacturability.

4. Modular Design for Large Parts

If fabricating a large part in one piece isn’t feasible, a modular design approach can improve manufacturing efficiency:

- Break parts into smaller, manageable sections that fit standard sheet sizes, minimizing material waste.

- Use interlocking tabs, slots, or dowels to simplify alignment and reduce assembly errors.

- Consider knock-down assemblies for easier shipping and final assembly at the point of use.

If you do decide to modify your part, we can share Design for Manufacturing (DFM) tips to help you optimize your design. Request a quote today and we’ll respond ASAP to discuss your part.