Last updated on February 6th, 2025 at 08:57 am

Offset bends are important for many everyday applications such as hinges, fasteners, chassis, and even electrical conduits. But the process of creating an offset can be complicated and time-consuming.

chassis, and even electrical conduits. But the process of creating an offset can be complicated and time-consuming.

Because offset bends are often too close together to be achieved with standard press brake tooling, many sheet metal fabricators and engineers turn to expensive offset tooling to get the precise forms required.

But what if we told you we’ve got a trick for forming custom offset bends?

And what if we told you that trick will save you from paying for yet another custom offset tool?

Table of Contents

- 1 At Approved Sheet Metal, we’re happy to share our secret for creating offset bends using the standard tooling most sheet metal shops like ours already have. Why? Because being the BEST is about always finding ways to help our customers succeed.

- 2 Sheet Metal Part Design for Manufacturing Tip

- 3 How to Create Sheet Metal Offsets without Custom Tooling

- 4 Custom Offset Tooling vs. Lazy Offsets: Which One is Right for Your Part?

- 5 Sheet Metal Offset Bend FAQ

- 5.0.1 What are offset bends and why are they important?

- 5.0.2 How can I create offset bends without custom tooling?

- 5.0.3 Do I need custom offset tooling for my part?

- 5.0.4 How do I determine the right tool for creating offset bends?

- 5.0.5 Can Approved Sheet Metal help with calculating and creating offsets for my bends?

How to Create Sheet Metal Offsets without Custom Tooling

To determine whether or not you need custom offset tooling for your part, first ask yourself: what’s more important, offset height or offset angle?

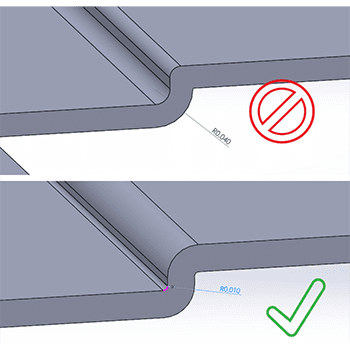

If offset height and angle are equally important for the part, then we recommend a custom offset tool. If, however, the offset height is more important than the offset angle, then we can achieve the bend you need by creating what’s called a “lazy offset.”

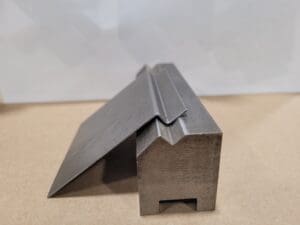

A lazy offset is an easy alternative solution when a part needs a specific height but doesn’t necessarily need a strict 90-degree offset angle. Here’s how we do it at our precision metal fabrication shop:

Step 1: We make sure we have the right tool.

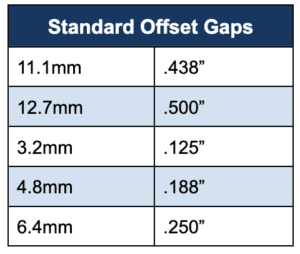

We calculate for the right V opening size by multiplying the offset tool height x 1.414.” Then, we select the appropriate tool by checking this chart.

Step 2: We set the press brake to how hard we want it to come down on the piece of metal.

We adjust the press brake tonnage according to the offset height you want to achieve. If you want a .2” offset, for example, we would use a .25” die but not press down as hard.

Step 3: We manually stop the press brake to create the desired angle.

This step is as simple as it sounds: we run the press then manually stop it at the desired angle to create the part that you’ve designed.

Yes—lazy offsets are that easy to make. . . when you work with the right precision metal fabrication shop!

Here are the standard offset gaps you can use for designing your bends. But the team at Approved Sheet Metal is always happy to calculate and create offsets for you as well!

Custom Offset Tooling vs. Lazy Offsets: Which One is Right for Your Part?

When designing a part with offset bends, you have two main options: investing in custom offset tooling or using a lazy offset with standard press brake tooling. Each method has its advantages, depending on your part’s requirements.

Custom Offset Tooling

Custom offset tools are specially designed to create precise offset bends with consistent height and angle in a single press brake operation.

✅ Pros:

- Guaranteed accuracy and repeatability of both offset height and angle.

- Faster production times with minimal manual adjustments.

- Ideal for high-volume production where efficiency is key.

❌ Cons:

- High upfront tooling costs, which may not be justified for low-volume orders.

- Longer lead times if custom tooling needs to be designed and manufactured.

- Less flexibility—tooling is designed for a specific offset height and angle.

Lazy Offsets (Using Standard Tooling)

A lazy offset is a press brake bending technique that allows you to form an offset without a dedicated offset tool. It prioritizes offset height over a strict 90-degree offset angle.

✅ Pros:

- No additional tooling costs, making it ideal for prototypes and low-to-medium volume production.

- Greater flexibility, as the press brake settings can be adjusted to achieve different offsets.

- Works well for designs where offset height is more critical than the angle.

❌ Cons:

- Slight variations in offset angles due to manual press brake stopping.

- Requires skilled operators to ensure consistency across multiple bends.

- Not suitable for parts that require both precise offset height and angle.

When to Choose Which Method

| Factor | Custom Offset Tooling | Lazy Offset |

|---|---|---|

| Precision Needed | High accuracy for both height and angle | Best for height-critical parts, minor angle variation acceptable |

| Production Volume | Best for high-volume runs | Ideal for low-to-medium volume and prototypes |

| Cost Considerations | Higher upfront cost for tooling | More cost-effective, no extra tooling needed |

| Flexibility | Fixed for specific offsets | Can be adjusted for different offsets |

| Lead Time | Longer due to tooling fabrication | Faster since it uses existing press brake tools |

The Bottom Line

If your part requires a strict 90-degree offset angle and will be manufactured in high volumes, custom offset tooling is worth the investment. However, if you need a cost-effective and flexible solution—especially for prototypes or lower-volume runs—lazy offsets are the smarter choice.

At Approved Sheet Metal, we help customers determine the best offset bending method for their parts. Not sure which one is right for you? Send us your design, and we’ll guide you to the best solution!

Next time your part needs offset bends, save yourself the hassle and the extra expense. Request a quote today.