Last updated on March 24th, 2025 at 09:45 am

Engineers commonly default to using steel hardware for their custom sheet metal parts—and it’s easy to understand why. Steel hardware is the cheapest and most ubiquitous option. If you have a steel part or a part that will be powder coated or zinc plated, steel hardware is a viable solution that will definitely save you some money.

But when you’re dealing with certain materials or processes, standard steel hardware can actually be detrimental to your parts.

Table of Contents

- 1 The Challenge with Steel Hardware

- 2 When Stainless Steel Hardware Is a Better Choice

- 3 Coating & Surface Treatment Implications

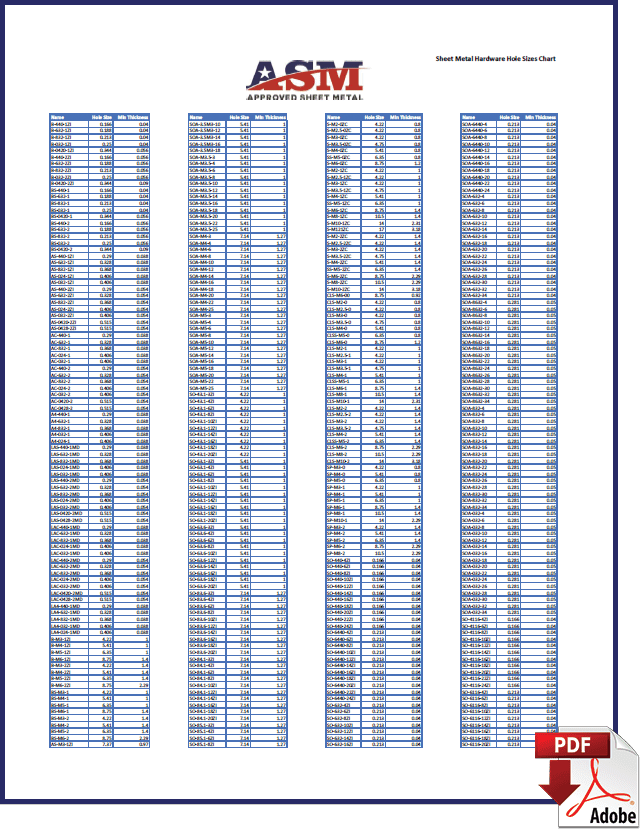

- 4 Sheet Metal Hardware Hole Sizes Chart

- 5 Sheet Metal Material and Hardware FAQ

- 5.0.1 When should I use steel hardware for my custom sheet metal parts?

- 5.0.2 Why should I avoid using steel hardware with aluminum or stainless steel parts?

- 5.0.3 When is stainless steel hardware a better choice than steel hardware?

- 5.0.4 Can stainless steel hardware be anodized like steel hardware?

- 5.0.5 How can I determine the appropriate hardware to use with different sheet metal materials?

The Challenge with Steel Hardware

If you’re using aluminum or stainless steel for your custom metal fabrication, you generally want to avoid steel hardware. Here’s why:

- Steel doesn’t stand up to plating. Aluminum parts are often plated after fabrication, but steel hardware won’t hold up during the plating process. If you’re planning to plate your aluminum parts, steel hardware will have to be inserted afterward, creating an additional step before getting your parts out the door.

- Steel is softer than stainless steel. When the hardware is softer than the material it’s fastening, the knurls won’t grip the material properly. There’s a good chance that the hardware will fall out instantly, or later when placed under pressure.

When Stainless Steel Hardware Is a Better Choice

In many applications, stainless steel hardware is a preferable alternative to steel. Here’s when stainless steel is the best choice:

- Stainless steel parts. Stainless steel hardware is hard and strong enough to grip stainless steel parts so they don’t succumb to pressure.

- Chromated aluminum parts. When steel is submerged in a chromate tank, the chemical reaction corrodes the steel almost immediately. Stainless steel, on the other hand, can withstand the chemicals in the tank. Although it’s possible to pair aluminum hardware with aluminum parts, we try to avoid it when we can. Aluminum hardware is significantly softer than stainless steel and doesn’t hold up as well.

What about anodizing? Like steel, stainless steel can’t be anodized. Depending on your part material, you have a couple of options. If you have a steel or stainless steel part, we recommend anodizing the part first and adding stainless steel hardware afterward. But if your part is made of aluminum, you could choose aluminum hardware and get the whole assembly anodized.

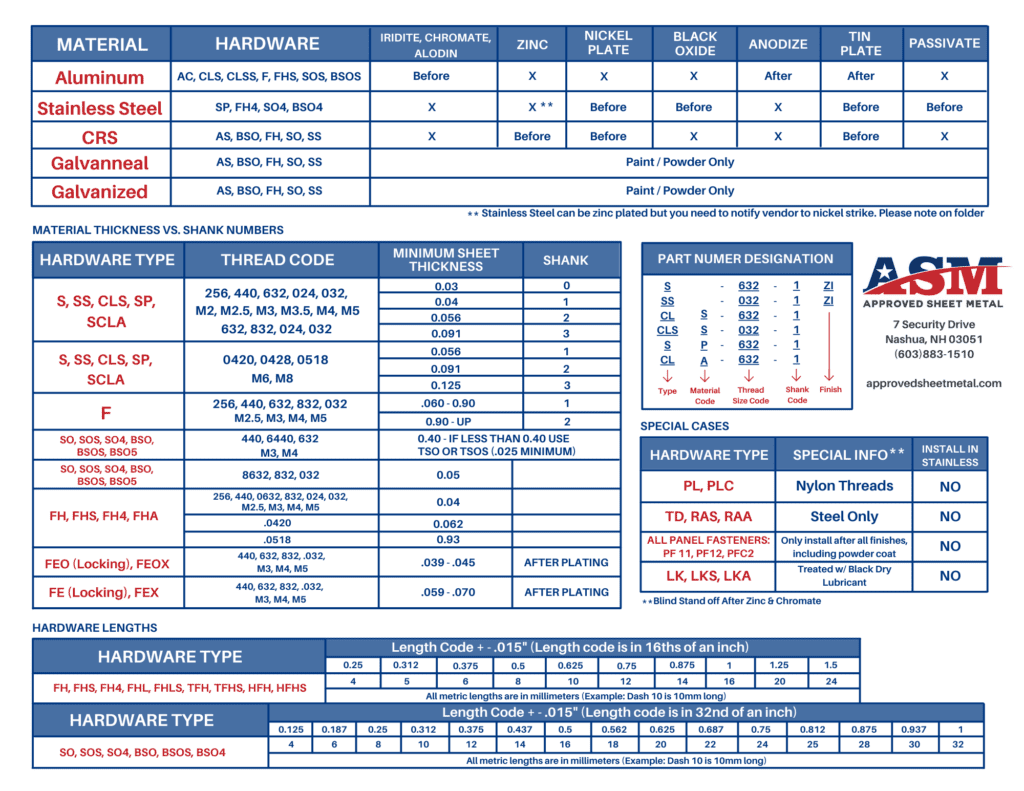

Here’s a chart to help you make sense of mixing and matching hardware with sheet metal materials:

Coating & Surface Treatment Implications

Choosing the right hardware material isn’t just about strength and compatibility—it also affects how well your parts perform after coating or surface treatment. Different coatings can impact corrosion resistance, aesthetics, and even mechanical properties. Here’s what you need to consider when selecting hardware for coated or treated parts:

1. Impact of Common Coatings on Hardware Selection

Powder Coating:

- Steel hardware works well with powder-coated steel parts, but zinc-plated steel or stainless steel can also be used.

- If powder coating is applied after hardware insertion, masking may be needed to prevent buildup on threaded fasteners.

Anodizing:

- Stainless steel and standard steel hardware do not anodize, so hardware should be added post-process.

- For fully anodized assemblies, aluminum hardware is the best choice.

Plating (Zinc, Nickel, or Chromate):

- Steel hardware may corrode or degrade in plating solutions used for aluminum parts.

- Stainless steel hardware is generally resistant to chemical treatments but should be tested for compatibility.

2. Avoiding Galvanic Corrosion Post-Treatment

When dissimilar metals are exposed to certain coatings or environments, galvanic corrosion can accelerate wear.

- Avoid pairing steel hardware with aluminum parts if the final part will be exposed to moisture.

- If mixed materials are required, consider using insulating washers or a protective barrier coating to minimize electrical conductivity.

3. Coating Thickness & Fitment Considerations

Some coatings add measurable thickness that can affect hardware fitment.

- Tight-tolerance parts may require adjustments in hole size before coating.

- Threaded fasteners may need post-coating re-tapping or the use of thread masking techniques.

Selecting the right hardware and considering surface treatments early in the design process ensures long-term durability and a seamless finishing process. If you’re unsure about the best hardware for your coated parts, consulting with your fabricator can help prevent costly rework or performance issues.

If the rules of mixing and matching hardware still seem complicated, don’t worry. At Approved Sheet Metal, our experts are well-versed in the appropriate hardware to use for your custom metal fabrications. We’ll make sure you’ve got the right hardware to ensure you get the best quality parts.

If you want to feel confident in your material and hardware combo, request a quote from Approved Sheet Metal today!