Last updated on May 22nd, 2025 at 10:21 am

With technology steadily becoming integrated into nearly every aspect of manufacturing, it’s more important than ever for your robotics and automation company to have a sheet metal manufacturing partner you can trust.

You’ll want to work with a manufacturer who can make high-quality small-batch parts and get them right the first time. As a high-mix, low-volume fabrication company, Approved Sheet Metal is the ideal partner for your robotics and automation needs.

Approved Sheet Metal is also a trusted sheet metal prototype service for robotics and automation research and development.

Whether you need a part that is critical to your current operations or an initial prototype for a concept still in the design phase, you’ll be glad you selected our expert team.

Table of Contents

- 0.1 Common Parts We Fabricate for the Robotics and Automation Industry

- 0.2 Common Materials for Robotics and Automation Applications

- 1 Fastening & Modular Assembly Methods for Robotics Applications

- 2 Sheet Metal Design for Manufacturing

- 3 Sheet Metal Fabrication for the Robotics FAQ

- 3.0.1 What types of parts does Approved Sheet Metal fabricate for the robotics and automation industry?

- 3.0.2 Which materials are commonly used by Approved Sheet Metal for robotics and automation parts?

- 3.0.3 What capabilities does Approved Sheet Metal offer specifically tailored for the robotics and automation industry?

- 3.0.4 How does Approved Sheet Metal support robotics and automation research and development through prototype services?

- 3.0.5 What advantages does working with Approved Sheet Metal offer to companies in need of robotics and automation parts?

Common Parts We Fabricate for the Robotics and Automation Industry

Approved Sheet Metal is proud to partner with industries that integrate cutting-edge robotics and automation technologies. We are the precision sheet metal fab partner who will keep your company moving forward.

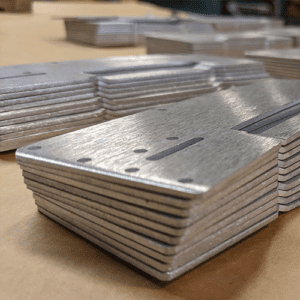

Here are the parts we fabricate most frequently for our robotics and automation customers:

- Plates

- Covers (e.g., custom covers for 3D printers)

- Enclosures

- Brackets (e.g., brackets for autonomous cars)

- Chassis (e.g., chassis for automated trash cans)

- Large-radius bump-formed parts

Common Materials for Robotics and Automation Applications

The three most commonly used materials for robotics and automation parts are stainless steel, cold-rolled steel, and aluminum.

Stainless steel 316

Stainless steel 316 is an ideal material for robotics applications, particularly in the medical sector. This high-strength metal is extremely corrosion-resistant and can withstand the high heat and harsh chemicals used in medical sterilization processes without distorting. It also has a polished surface—perfect for applications that must be sterile at all times.

Cold-rolled steel

Available in an array of thicknesses, cold-rolled steel is known for its excellent flatness tolerance, surface finish, and press brake formability, making it a great choice for robotics and automation applications.

Aluminum 5052

While aluminum 5052 isn't the strongest aluminum available, it is frequently used in medical robotics applications because of its excellent weldability, formability, and rust resistance.

When we work on your custom metal fabrication, we'll walk you through your options and make sure you're using the material that best fits your needs.

Fastening & Modular Assembly Methods for Robotics Applications

In robotics and automation systems—where maintenance access, flexibility, and rapid upgrades are key—

modular design and efficient fastening methods are essential. At Approved Sheet Metal, we support engineers

in selecting fastening and joining solutions that balance structural integrity with ease of assembly and long-term serviceability.

Common Fastening Solutions

We regularly integrate a variety of hardware into robotic components:

- PEM® self-clinching fasteners (nuts, studs, standoffs): Ideal for thin sheet metal, providing strong, reusable threads without welding or tapping.

- Blind rivets and rivet nuts: Excellent for joining multiple layers when access is limited to one side.

- Machine screws and threaded inserts: Great for enclosures and service panels requiring frequent access.

- Snap-fit and tab-lock features: Designed into the sheet metal geometry for tool-less assembly or alignment.

These methods are particularly useful in automation systems where modularity and reconfiguration are expected during field deployment or upgrades.

Benefits of Modular Design in Robotics

Robotics systems—especially in warehousing, manufacturing, and medical automation—benefit significantly from modular metal components:

- Rapid Maintenance and Repairs

Components can be quickly swapped or upgraded without disassembling the entire system. - Improved Manufacturability

Sub-assemblies can be produced and tested independently, increasing build quality and reducing lead times. - Scalable Production

Modular designs are easier to scale from prototype to low-volume production with minimal design revisions. - Reduced Downtime

Engineers can replace individual brackets, covers, or enclosures on-site rather than waiting for full-system rebuilds.

Design Tips for Engineers

To optimize your sheet metal designs for fasteners and modularity:

- Use standard hole sizes and fastener clearances based on available PEM hardware.

- Design for easy tool access during assembly (consider socket depth and driver angles).

- Incorporate alignment features (tabs, pins, or dowels) to ensure repeatable assembly.

- Avoid over-specifying welded joints if modular assembly can achieve similar performance.

How ASM Supports the Robotics and Automation Industry

At Approved Sheet Metal, we leverage several in-house capabilities to serve robotics and automation customers. Here’s what you can expect from our shop:

- Sheet metal forming, so you can get precisely formed parts FAST

- Class A sheet metal finishing to ensure sanitation in biomedical applications

- Laser cutting is conducted by experts who have more than 15+ years of experience

- Stainless steel tubular frame construction for medical equipment

- Various welding services, including MIG, TIG, and spot welding

- Sheet metal assemblies shipped out in 10-14 days, with expedited options available

- Specialty powder coating and color anodizing services for an attractive, cohesive appearance

Looking for a custom fabrication shop you can count on for quality robotics and automation parts and assemblies? Request a quote today!