Last updated on March 31st, 2025 at 10:08 am

Laser cutting is a versatile sheet metal fabrication process that creates precise cuts with minimal material waste—but it can be expensive.

A number of factors contribute to the cost of laser cutting services, from material thickness to the complexity of a part’s features.

In some cases, simple design modifications can reduce the cost of laser cutting services. But your best bet is to work with a full-service metal fabrication shop that offers laser cutting and punch press services and can choose the most cost-effective solution when preparing a quote.

Table of Contents

- 1 Laser Cutting or Punch Press?

- 2 3 Cost-Cutting Tips for Laser Cutting Services

- 3 Tolerance Considerations & Precision in Laser Cutting

- 4 Choose ASM for Laser Cutting Services, Punch Press Services, and More

- 5 Sheet Metal Design for Manufacturing

- 6 How To Minimize the Cost of Laser Cutting Services FAQ

- 6.0.1 What factors contribute to the cost of laser cutting services?

- 6.0.2 How can design modifications affect the cost of laser cutting services?

- 6.0.3 When should I opt for laser cutting over punch press services, and vice versa?

- 6.0.4 Are there cost-saving strategies for laser cutting services?

- 6.0.5 What unique capabilities does ASM offer for cost-effective laser cutting services?

Laser Cutting or Punch Press?

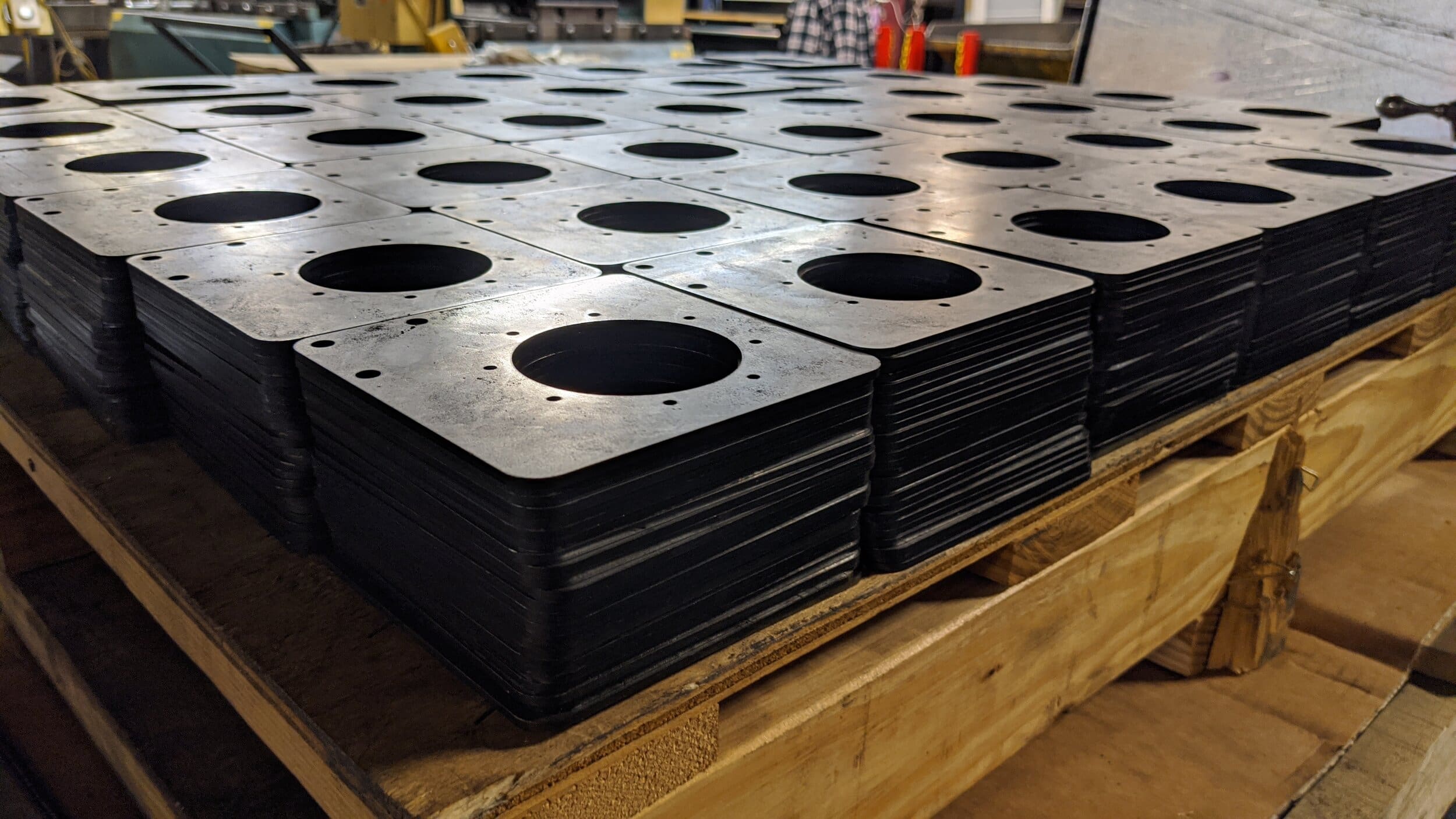

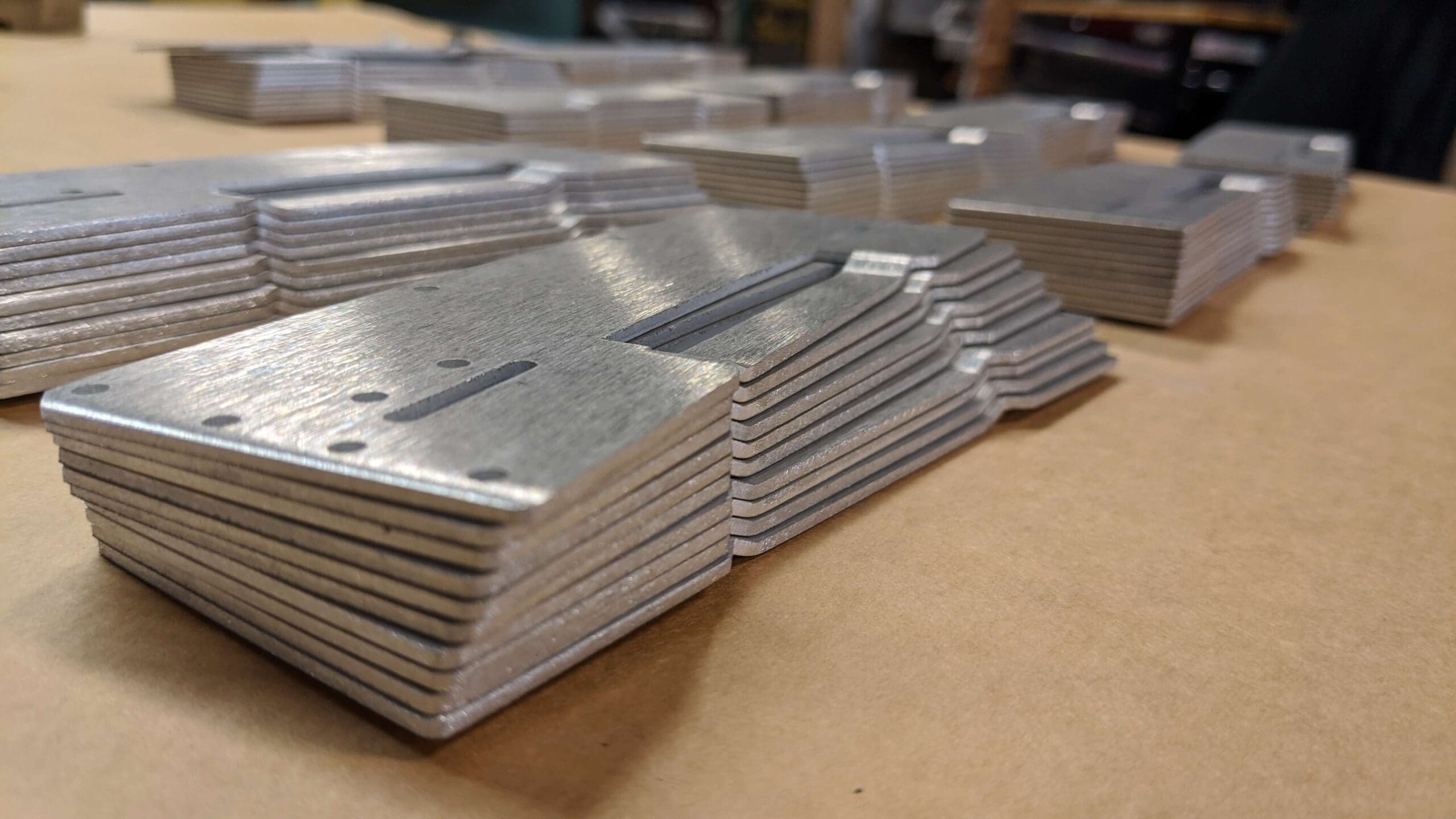

Often, we review designs intended for laser cutting with features we could fabricate much more cost-effectively using our punch press. This is just one example of how our multiple in-house capabilities enable us to deliver the results our customers want at a lower price point.

A laser cutter uses a high-power laser beam to cut material. A punch press uses tooling and

requires a longer setup process, which can be associated with higher costs. However, for some parts, the operational cost of using a punch press is less expensive than using a laser cutter.

It really depends on the project. If, for instance, we need to order custom tooling to achieve detailed features, our punch press likely isn’t the best solution for a low volume of parts. But if you need hundreds of that same part, the cost of custom tooling could be worth it.

When we review your quote request, we’ll help you determine the optimal solution.

Sometimes, the decision isn’t “either-or” but “both”! Punch forming and laser cutting can work together as a dynamic duo. In fact, we’re currently using both capabilities for a customer’s part: laser cutting services to cut the main geometry and our punch press to add louvers.

3 Cost-Cutting Tips for Laser Cutting Services

When laser cutting is the optimal approach for your part, there are some steps you can take to minimize costs.

Use a thinner material

The thicker the material, the longer it will take us to cut it, and the more you’ll pay for laser cutting services. Consider whether a thinner material might work just as well for your part.

Choose an in-stock material

Is the material you’ve requested readily available, or will it require a special order? When possible, selecting a metal that’s in stock will prevent you from paying minimum order charges.

Simplify complex features

Does your design include complex features? Are they essential to the part’s functionality, or were they added primarily for aesthetic appeal? If you’re on a tight budget, simplifying complex features that aren’t strictly necessary can make a big difference.

Tolerance Considerations & Precision in Laser Cutting

Impact of Tight Tolerances on Cost

Laser cutting is highly precise, but unnecessary tight tolerances can significantly increase costs. Here’s why:

- Longer Cutting Time: The laser must slow down for intricate features and tight tolerances, increasing machine time.

- Higher Scrap Rate: Parts with extremely tight tolerances are more likely to be rejected due to slight deviations.

- Additional Secondary Processes: If tolerances are too strict, post-processing like machining or grinding may be required to achieve the desired precision.

Optimizing Tolerances:

- Instead of specifying ±0.005”, consider whether ±0.010” or ±0.015” would suffice without affecting functionality.

- Consult with your fabricator early to ensure tolerances are achievable without unnecessary cost.

Burr Formation & Edge Quality

The quality of laser-cut edges depends on material type, thickness, and cutting parameters:

- Thicker materials tend to produce more burrs, requiring secondary finishing like deburring or sanding.

- High-carbon steels are more prone to oxidation at cut edges, which may require additional cleaning.

- Nitrogen cutting produces cleaner edges compared to oxygen, but at a higher operating cost.

Tip: If edge quality is critical for fit or welding, discuss this with your fabricator to optimize cutting parameters.

Thermal Expansion & Warping

Laser cutting generates heat, which can cause slight distortions in some materials.

- Thin sheet metal is more prone to warping, especially with intricate features or long cuts in a small area.

- Strategic Tab Placement: Adding small tabs to hold parts in place can prevent warping during cutting.

- Material Choice Matters: Aluminum dissipates heat differently than steel, affecting cut precision.

Choose ASM for Laser Cutting Services, Punch Press Services, and More

ASM consistently goes above and beyond to help customers get the desired results for the right price, including creating in-house resources to support design optimization.

Our proprietary louver tool, for instance, makes it easy for customers to design manufacturable louvers in SOLIDWORKS. We’re also compiling a standard tooling inventory so customers know which tooling we have in-house and can design their parts accordingly to avoid custom tooling charges.

Request a quote to get started with our team today!