Last updated on February 18th, 2026 at 10:32 am

Surface finish is an essential consideration for many sheet metal fabrication projects, including, most commonly, parts requiring beautiful cosmetic appearances and pharmaceutical or medical-grade parts that need to perform in clean environments.

Today, we’ll take a closer look at different surface finishing scales as well as surface finish considerations to ensure you get the exact parts you need.

Table of Contents

- 1 Surface Finish Scales for Sheet Metal Fabricated Parts

- 2 Creating Beautiful Surface Finishes for Sheet Metal Fabricated Parts

- 3 How to Specify Surface Finish on a Drawing or RFQ

- 4 Surface Finish Considerations for Sheet Metal Fabricated Parts

- 5 Grain Direction and Part Layout

- 6 Protecting Cosmetic Surfaces Through Fabrication

- 7 Common Surface Finish Mistakes

- 8 Recommended Default Sheet Metal Tolerances

- 9 Sheet Metal Surface Finish FAQ

- 9.0.1 What is surface finish, and why is it important in sheet metal fabrication?

- 9.0.2 What are some commonly used surface finish scales for sheet metal fabricated parts?

- 9.0.3 How can I achieve the best surface finish for my sheet metal fabricated parts?

- 9.0.4 What should I consider before specifying surface finish requirements for my sheet metal fabricated parts?

- 9.0.5 How does Approved Sheet Metal ensure that my sheet metal fabricated parts meet my surface finish requirements?

Surface Finish Scales for Sheet Metal Fabricated Parts

There are several different ways to measure the surface finishes of sheet metal fabricated parts.

Fabricators, machinists, and metal finishers often use the highly technical Ra (Roughness Average) scale, which measures the average surface heights and depths across a surface. The problem is that maintaining a specific Ra value is difficult at a microscopic level for sheet metal fabricated parts, and it isn’t essential for many sheet metal applications.

An alternative method is to indicate the grit, the number of scratches per linear inch of abrasive pad, that should be used to finish a part. Higher grit values indicate smoother surface finishes. This is one of the more common ways that sheet metal fabricators and customers communicate about surface finish requirements.

However, the easiest and best way to specify surface requirements for sheet metal fabricated parts is to use the preferred scale for the source material. For example, we would use this simple scale for stainless steel:

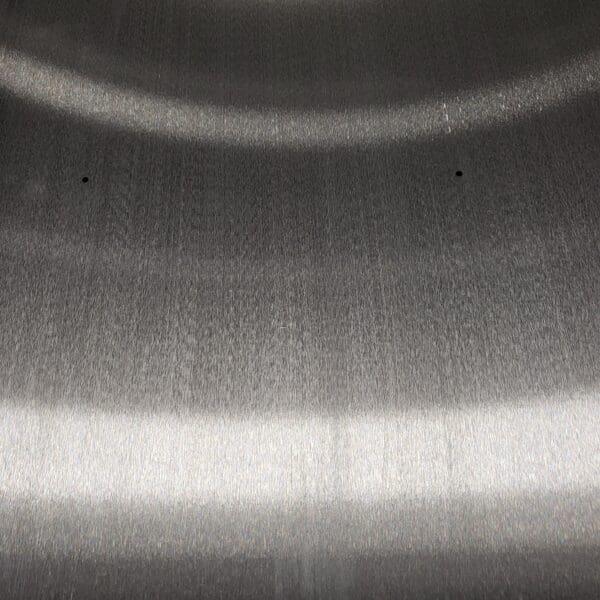

- 2B: Bright, Cold Rolled

- 3: Brushed, 120 Grit

- 4: Brushed, 150 Grit

- 8: Mirror

- BA: Bright Annealed

Quick Stainless Finish Cheat Sheet

| Finish | Typical Look | Best For | Notes |

|---|---|---|---|

| 2B | Lightly reflective, smooth mill finish | General fabrication, internal parts, sanitary applications | Good baseline finish; fingerprints show less than mirror finishes |

| #4 | Brushed, visible grain | Cosmetic panels, covers, visible enclosures | Grain direction should be specified when appearance matters |

| BA | Bright, more reflective than 2B | Clean environments, cosmetic parts needing a brighter look | More reflective means scratches can be more noticeable |

| #8 | Mirror | High-visibility cosmetic surfaces | High cost and handling sensitivity; best when truly required |

Ra vs Grit vs Mill Finish

- Ra (Roughness Average): A measured requirement. Best when function matters, such as sealing surfaces, sliding interfaces, or cleanability targets.

- Grit: A process-based requirement. Common for brushed appearances and consistent directionality.

- Mill finish (2B, #4, BA, etc.): Often the fastest and most cost-effective way to get a predictable surface appearance. Starting with the right material finish usually beats trying to “finish it in” later.

Creating Beautiful Surface Finishes for Sheet Metal Fabricated Parts

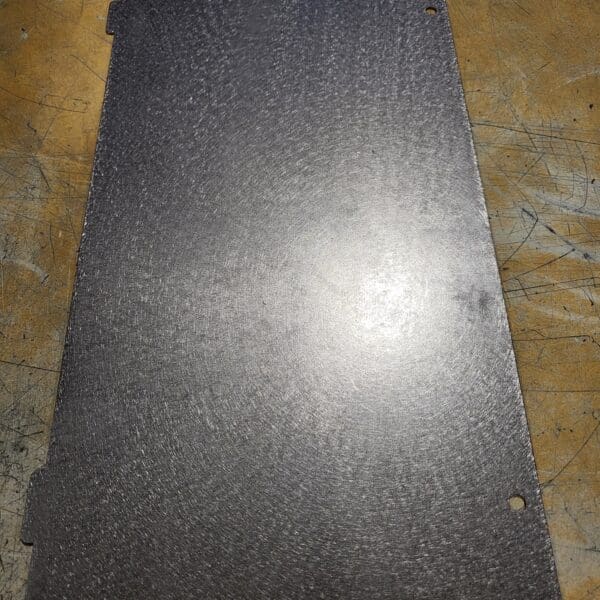

To achieve the best surface finish possible for sheet metal fabricated parts, we recommend sourcing a material that already has a surface finish comparable to the desired finish. Then, we can use one of these standard methods to clean it up even further:

- Employing our Timesaver Abrasive Belt Finishing Machine to clean up the surfaces of sheet metal fabricated parts and get them to spec. This machine is capable of deburring, edge rounding, finishing, laser oxide removal, and heavy slag removal.

- Using successively finer belts and compounds to achieve a near mirror finish, although this type of finish typically isn’t required for sheet metal fabricated parts.

What the Timesaver Helps With (and What It Doesn’t)

- Great for: consistent deburring, edge rounding, blending light handling marks, and cleaning up laser-related discoloration on certain materials.

- Not a magic fix for: deep scratches, dents, or cosmetic damage that starts in the raw stock. If appearance is critical, choosing the right source material and protecting it throughout fabrication matters more than any final finishing pass.

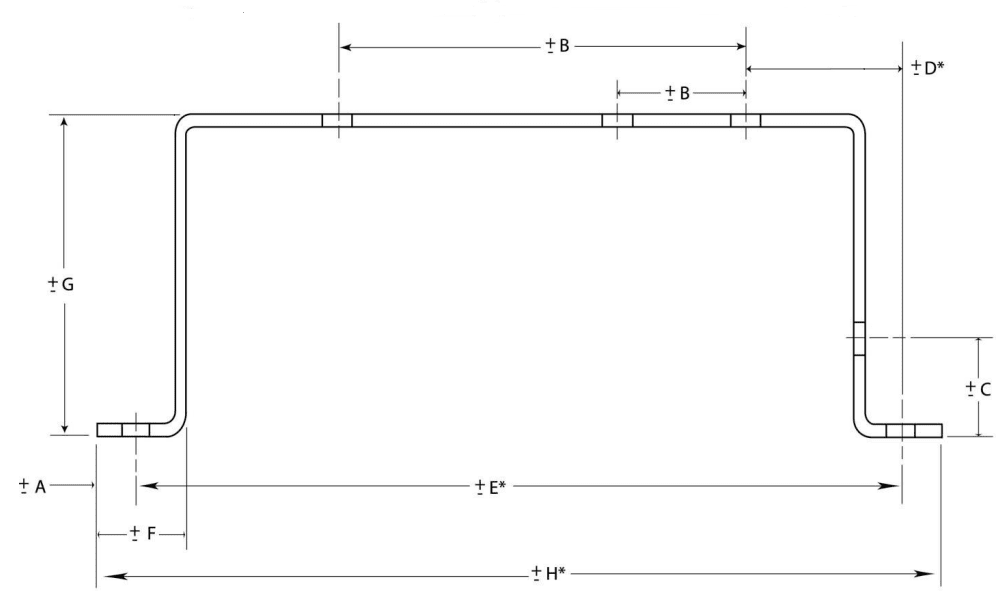

How to Specify Surface Finish on a Drawing or RFQ

If you want the fastest quote and the best chance of getting exactly what you expect, it helps to be specific about what matters and where it matters.

- Call out the source finish when applicable (for example, 2B, #4, BA, or #8 for stainless).

- Define the cosmetic side (Side A / Side B). If only one face is customer-visible, this can reduce cost and prevent unnecessary handling.

- Specify grain direction for brushed finishes. Parts can be nested in different orientations during cutting unless direction is called out.

- If you truly need a measured requirement, specify an Ra maximum that matches the function and is realistic for sheet fabrication.

- If the part will be painted or powder coated, note the coating system and that overly smooth surfaces can telegraph imperfections.

Surface Finish Considerations for Sheet Metal Fabricated Parts

Consider these factors before specifying surface finish requirements for your sheet metal fabricated parts:

- A higher surface finish doesn’t necessarily result in a better aesthetic appearance. Surface finishes with exceptionally low Ra values can lose some of their grain, which can compromise the appearance of the finish in certain cases.

- The smoothest surfaces aren’t always ideal for painting and powder coating. If you plan to have your sheet metal part painted or powder-coated, we recommend leaving some texture on the surface. When the surface is too smooth, these additional finishing operations will highlight any scratches or imperfections. A slightly textured surface yields a more uniform appearance.

- Achieving an exceptionally smooth surface finish adds cost and time to a project. You can save time and money by minimizing surface finish operations on sheet metal fabricated parts. You may consider this option for sheet metal prototypes or internal parts that don’t need to be aesthetically perfect.

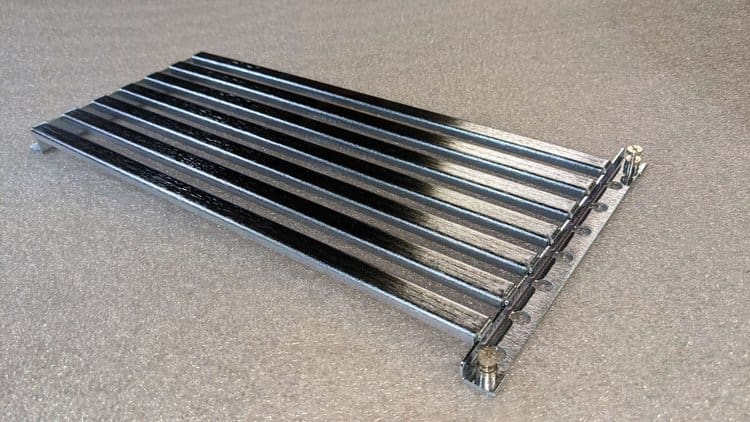

Grain Direction and Part Layout

For brushed stainless and other directional finishes, grain direction is one of the most common “expectation gaps” between a drawing and the delivered part.

- Grain direction can change if parts are rotated during nesting. If the brushed direction matters, call it out.

- Assemblies should match. When multiple cosmetic panels sit next to each other, mismatched grain direction is noticeable even if the finish grade is correct.

- Communicate the reference. If you need grain to run parallel to a bend line, parallel to the longest edge, or vertical in the installed orientation, specify it.

Protecting Cosmetic Surfaces Through Fabrication

Cosmetic finishes are easiest to achieve when the surface is protected from the start. Many “finish issues” are actually handling issues.

- Protective film (when available) can help prevent scratches during cutting, forming, and assembly.

- Hardware insertion and welding can introduce marks near the cosmetic face. If appearance is critical, it helps to define which face is cosmetic and where light tool marks are acceptable.

- Racking and transport can create contact points. Clear expectations about acceptable appearance help avoid surprises.

Industry-Specific Applications

Surface finishes in sheet metal fabrication play a crucial role across various industries, with each sector having unique requirements based on the applications of their products. Below are some examples of industry-specific applications where surface finish is critical:

1. Medical and Pharmaceutical Industries

- Key Requirements: High-grade finishes like 2B, BA, or mirror finishes to support cleanability and reduce contamination risk.

- Applications: Surgical instruments, medical device enclosures, and cleanroom equipment.

- Standards: Requirements may be driven by ISO 13485 or FDA expectations depending on the device and environment.

2. Food and Beverage Industry

- Key Requirements: Smooth, non-porous finishes (for example, 2B or BA) that are easier to clean and less likely to harbor contaminants.

- Applications: Stainless steel tanks, food processing machinery, and kitchen equipment.

- Standards: Surface finishes must meet applicable NSF and USDA guidelines for food safety.

3. Aerospace Industry

- Key Requirements: Lightweight parts with corrosion-resistant finishes and controlled surface roughness where function requires it.

- Applications: Aircraft panels, turbine-related components, and structural parts.

- Standards: Often tied to AS9100 environments and customer-specific finish callouts.

4. Electronics and Semiconductors

- Key Requirements: Consistent surface conditions for fit, grounding, and shielding where required, including considerations for EMI.

- Applications: Enclosures for sensitive electronics, heat sinks, and semiconductor manufacturing equipment.

5. Automotive Industry

- Key Requirements: Cosmetic consistency for visible parts and durable corrosion protection for functional parts.

- Applications: Exterior and interior panels, brackets, and structural components.

- Standards: Often driven by OEM benchmarks for appearance and durability.

Surface Finish vs. Functionality

Surface finishes not only enhance the aesthetic appeal of sheet metal parts but also play a critical role in their functionality. Below are some ways surface finish directly impacts a part's performance:

1. Corrosion Resistance

- A smoother surface finish, such as a mirror or BA finish, minimizes crevices where moisture or chemicals can accumulate, reducing the likelihood of corrosion.

- Industries like marine and food processing often require these finishes for longevity in corrosive environments.

2. Friction and Wear Resistance

- Components requiring low friction, such as sliding parts in machinery, can benefit from polished or DA sanded finishes to minimize wear and extend the lifespan of the parts.

3. Adhesion for Coatings

- A slightly textured surface finish, such as one achieved with grit blasting, improves the adhesion of paints, powder coating, or adhesive films. Conversely, overly smooth surfaces can lead to peeling or flaking.

4. Thermal and Electrical Conductivity

- Highly polished surfaces can support better conductivity in electrical and thermal applications, such as heat sinks or electronic enclosures.

5. Cleanability and Hygiene

- In industries like healthcare and food processing, smoother finishes reduce contamination risks and make surfaces easier to clean, maintaining hygiene standards.

6. Structural Integrity

- Excessively rough finishes can create stress concentrations, leading to cracks or failures under load. Specifying an appropriate surface finish can enhance durability and reliability.

Common Surface Finish Mistakes

- Not defining the cosmetic face and expecting all faces to be perfect.

- Skipping grain direction callouts on brushed finishes and getting inconsistent appearance across parts.

- Assuming a mirror finish will stay perfect through forming, welding, and assembly without added protection.

- Over-specifying Ra when a source finish or grit callout would achieve the real requirement more efficiently.

- Expecting coatings to hide defects. Paint and powder coat can highlight scratches if the base surface is too smooth or inconsistent.

At Approved Sheet Metal, we’re committed to delivering sheet metal fabricated parts that meet customers’ specifications and will always do what it takes to achieve the surface finish you desire. Our attention to detail and obsession with quality is second to none. Request a quote today, and we’ll respond ASAP!