At Approved Sheet Metal, we excel at chassis fabrication. Whether it's a one-off prototype or a production-ready assembly, our team has extensive experience delivering high-precision, highly functional chassis for customers across aerospace, electronics, industrial automation, telecommunications, and beyond. These parts often form the structural foundation of complex systems and must meet exacting standards for strength, fit, finish, and repeatability. With decades of expertise in custom sheet metal fabrication, we’ve developed streamlined processes to build chassis that look and perform exactly as intended.

Our ability to balance design intent with manufacturability is what sets us apart. We work directly with engineers to optimize every chassis for performance and cost, providing design for manufacturability (DFM) feedback from the start. From custom aluminum fabrication for electronics to rugged stainless steel fabrication for industrial environments, we’re proud to be the fabrication company behind some of the most critical structural components in advanced industries today.

Table of Contents

Common Types of Chassis

Chassis come in a wide variety of shapes, sizes, and configurations, each tailored to a specific application and functional need. One of the most common types we fabricate is the rackmount chassis, used widely in the electronics and telecommunications industries. These enclosures house sensitive electronic components and are designed for seamless integration into server cabinets or equipment racks. They typically feature ventilation cutouts, grounding points, PEM hardware, and durable powder-coated finishes to support both thermal performance and professional aesthetics.

Another frequent request is the instrument chassis, often built as part of a full box build. These parts serve as the structural skeleton for lab instruments, testing devices, and diagnostic tools. Since they are frequently customer-facing, the focus is not only on form and function but also on cosmetic detail. Tight cutouts, smooth edges, and precision mounting features are all critical. We also manufacture power supply chassis, designed to support transformers and high-voltage components. These often require thicker gauges, robust internal brackets, and perforations for airflow and heat dissipation.

Industrial base chassis and subframes are yet another category, typically forming the backbone of kiosk systems, robotic platforms, or large industrial machines. These are often welded assemblies that require fixturing, reinforced corners, and stress-relief measures to ensure strength and stability. Finally, control panel enclosures are essential for electrical or pneumatic system integration. These include hinged panels, gasketing, and may even require EMI/RFI shielding or NEMA-rated construction. Whatever the use case, our experience allows us to deliver precision metal fabrication solutions tailored to your application.

The Process of Chassis Fabrication

Every successful chassis begins with a solid foundation: a detailed engineering review. Our DFM process helps identify cost-saving opportunities and resolves design challenges early, such as minimizing tight tolerances or avoiding complex bends. Once designs are finalized, we generate flat patterns and toolpaths based on the customer’s 3D model. Programming ensures that laser cutting, punching, and bending operations will run smoothly on our equipment and yield high accuracy.

Material selection is next. Chassis fabrication typically involves alu minum, stainless steel, or cold rolled steel, pulled from stock based on the required thickness and spec. The flat blank is cut using CNC laser equipment for precise profiles, mounting holes, and ventilation patterns. The part then moves to our press brake for forming, where flanges, walls, and stiffeners are bent to spec. We use advanced simulation software and custom tooling when necessary to ensure consistent bends, even for complex multi-flange designs.

minum, stainless steel, or cold rolled steel, pulled from stock based on the required thickness and spec. The flat blank is cut using CNC laser equipment for precise profiles, mounting holes, and ventilation patterns. The part then moves to our press brake for forming, where flanges, walls, and stiffeners are bent to spec. We use advanced simulation software and custom tooling when necessary to ensure consistent bends, even for complex multi-flange designs.

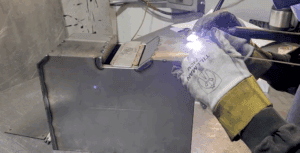

After forming, PEM hardware (such as standoffs and fasteners) is installed. Welding and assembly may follow, especially for large base frames or multi-piece structures. Here, we carefully control heat and distortion using strategic fixturing and low-heat processes like TIG welding.

Surface finishing is the next step, and we offer everything from anodizing and plating to powder coating and chem film, depending on your material and performance requirements. Silk screening or laser marking can be added for branding or labeling. Before shipping, every chassis undergoes rigorous inspection for dimensional accuracy, hardware placement, and overall quality. This comprehensive workflow ensures that our sheet metal services meet the most demanding specifications.

Industrial Applications of Chassis

Chassis are the unsung heroes of modern technology, providing the structure and protection that countless systems depend on. In the electronics and instrumentation sector, chassis are used for everything from rackmount enclosures to sensitive test equipment housings. These require careful thermal management, ESD protection, and often have complex internal mounting requirements. Our ability to produce custom sheet metal solutions for these use cases has made us a preferred partner for OEMs and engineers alike.

In aerospace and defense, chassis are mission-critical. We fabricate avionics boxes, communication modules, and control system enclosures that must meet strict quality and documentation standards. Our precision sheet metal capabilities and ITAR registration give customers peace of mind that their parts are built to perform under extreme conditions. In industrial automation, chassis support control systems, robots, and sensors, requiring robust construction and consistent repeatability. Similarly, the renewable energy sector relies on chassis for battery management systems, inverters, and solar controllers, where environmental resistance and heat dissipation are key.

Medical device manufacturers also rely on metal fabrication shops like ours for diagnostic equipment housings and lab system frames. These chassis must meet high standards for cleanliness, corrosion resistance, and cosmetic finish. Across all of these industries, what sets us apart is our ability to support a wide range of materials, finishes, and complexity levels all under one roof.

Materials Commonly Used for Chassis

Aluminum (5052-H32, 6061-T6): Aluminum is a popular choice for chassis fabrication due to its lightweight properties and excellent corrosion resistance. 5052-H32 is preferred for forming because it resists cracking and offers a smooth surface. 6061-T6 is stronger but less formable, often used for flat or machined components.

Cold Rolled Steel (CRS): CRS is a strong, cost-effective material ideal for industrial and indoor applications. It forms well, welds easily, and is typically powder coated or plated to enhance corrosion resistance.

Stainless Steel (304, 316): Known for its strength and clean finish, stainless steel is widely used in medical, food-grade, and outdoor applications. 304 is the most common grade, while 316 offers superior corrosion resistance for harsh environments.

Galvanized and Galvanealed Steel: These steels offer built-in corrosion protection and are often used in utility enclosures, electrical panels, and telecom chassis. Galvanealed steel provides a better surface for painting and powder coating.

Your Trusted Partner for Custom Chassis Fabrication

Chassis fabrication is one of our core strengths at Approved Sheet Metal. With decades of hands-on experience, a deep understanding of design challenges, and full-service capabilities under one roof, we’re trusted by engineers and OEMs who demand quality, speed, and reliability. From concept to completion, we bring your custom metal fabrication project to life with precision, consistency, and unmatched support.

Looking for a custom fabrication shop that knows chassis fabrication inside and out? Contact us today and let Approved Sheet Metal help you build the foundation of your next great product.