Last updated on January 29th, 2026 at 12:39 pm

Need your custom sheet metal part… yesterday?

If other shops are taking their sweet time, Approved Sheet Metal is built to move faster.

With our new facility and best-in-class equipment, we now have four times the capacity we did previously, allowing us to deliver rapid sheet metal prototypes with even shorter lead times.

Expediting custom sheet metal parts is our specialty. Our digitized quoting system allows for speedy RFQ processing so we can answer quotes in 4 hours or less. We also offer a same-day rush service for flat laser cut sheet metal parts that can arrive at your door within 24 hours of placing an order.

If you need your sheet metal prototype faster than ever, here are a few practical ways to speed up the process:

Table of Contents

- 1 How to Get Your Sheet Metal Prototype Faster Than Ever

- 2 Sheet Metal Design for Manufacturing

- 3 Expediting Sheet Metal Prototypes FAQ

- 3.0.1 How has Approved Sheet Metal improved its capacity to expedite sheet metal prototypes?

- 3.0.2 How quickly can I expect a quote for my sheet metal prototype from Approved Sheet Metal?

- 3.0.3 What are some tips for expediting the sheet metal prototype process?

- 3.0.4 How can selecting in-stock material speed up the delivery of sheet metal prototypes?

- 3.0.5 Why is mechanical fastening recommended for those prioritizing lead time in sheet metal prototypes?

How to Get Your Sheet Metal Prototype Faster Than Ever

Tip #1: Choose in-stock material.

We can deliver sheet metal prototypes an average of four days faster when customers select an in-stock material.

Check out our Same Day Materials list to see which types of aluminum, steel, stainless steel, and galvanized steel we have on the shelf and ready to go.

Tip #2: Provide a CAD file.

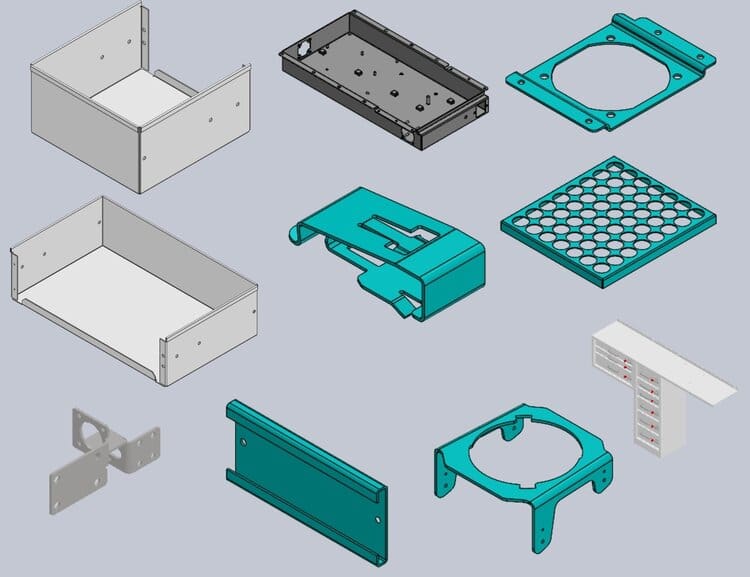

3D CAD technology accelerates lead times on sheet metal prototypes by providing full visibility into the part, simplifying assemblies, and minimizing design ambiguities.

If you do not have a CAD file yet, we can create one for you and deliver your part within a week. If speed is critical, submitting a CAD file along with your RFQ can reduce lead time to as little as three days.

Tip #3: Choose mechanical fastening instead of welding.

In some cases, welding is a simpler solution than fastening from a design standpoint. However, when lead time is the top priority, mechanical fastening is often the faster option.

Welding requires certified technicians whose labor is in high demand, and the associated inspection processes can extend timelines.

If you need fast assembly or added strength, using hardware such as screws, nuts, rivets, and rivnuts can significantly reduce turnaround time.

Tip #4: Forego material finishing.

Post-processing and finishing operations add time to any project, so look for opportunities to minimize or eliminate these steps when possible.

If corrosion resistance or appearance is required, using galvanized material or stainless steel instead of zinc plating can save three to five days of additional processing. For demo parts that will not be exposed to outdoor elements, skipping finishing altogether can further reduce lead time.

Ready to get your sheet metal prototype faster than ever? We have turned formed parts around in as little as 24 hours. Send it our way. At Approved Sheet Metal, we are committed to making the process faster, easier, and more reliable.