Last updated on February 2nd, 2026 at 02:50 pm

Do you need precision sheet metal prototypes fast?

At Approved Sheet Metal, we know

sheet metal prototyping

is all about time. Time is effort. Time is money. Time is often what determines whether a project succeeds or stalls.

It’s time to stop stressing about prototype lead times. Let us expedite your precision sheet metal

prototypes

so you can hit critical deadlines without sacrificing quality.

Table of Contents

- 1 Selecting In-Stock Materials Expedites Sheet Metal Prototype Fabrication

- 2 Sheet Metal Design for Manufacturing

- 3 Expedited Sheet Metal Parts FAQ

- 3.0.1 What is the typical turnaround time for sheet metal prototypes at Approved Sheet Metal?

- 3.0.2 Does Approved Sheet Metal offer welding services for quick-turn prototyping?

- 3.0.3 How does Approved Sheet Metal ensure rapid fabrication for precision prototypes?

- 3.0.4 What sets Approved Sheet Metal apart from competitors regarding speed and quality?

- 3.0.5 How quickly does Approved Sheet Metal respond to quote requests?

Selecting In-Stock Materials Expedites Sheet Metal Prototype Fabrication

There’s no need to source your own materials. To support rapid turnaround, we proactively stock the

most popular gauges

of steel (including stainless and galvanized) and aluminum.

When you select a material we already have in-house, we can typically expedite your job in as few as 2–5 days.

If we don’t have your required material on the shelf, we’ll source it as quickly as possible and keep you informed every step of the way.

For more complex fabrication orders, we consistently deliver precision sheet metal prototypes at the low end of quoted expedited timelines.

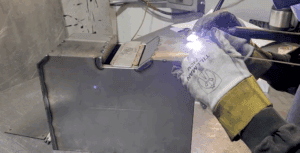

Yes, Welding Is Included

Many fabrication shops exclude

welding

from quick-turn prototyping. We don’t.

Our welding experts bring 20+ years of experience and routinely deliver high-quality welded prototypes under extremely tight timelines.

Our Culture of Efficiency Drives Rapid Sheet Metal Prototype Fabrication

If you needed your parts yesterday, we’re the shop to call.

Speed is a priority across our entire operation. That’s why it’s company policy to respond to all

quote requests

within 4 hours or less.

We’ve built a culture of efficiency designed to support tight turnaround times for precision sheet metal prototypes. Here’s how we maintain that sense of urgency:

1. Advanced software

Our secure quoting platform enables fast, accurate pricing so production can begin quickly. In addition, our custom ERP technology uses artificial intelligence to track material inventory and manage schedules for maximum efficiency.

2. Proactive communication

We’re always just a phone call away. Our

dedicated team members

are empowered to solve problems quickly, and because our entire team operates from one facility, communication stays clear and immediate.

3. Knowledgeable team members

We strive to be the best

at what we do, which means continuously training our team on new equipment, workflows, and fabrication techniques. That investment directly translates into faster, more reliable prototype delivery.

4. High-speed laser capabilities

A typical CO₂ laser cuts .059" aluminum or steel at roughly 60 inches per minute. Our

AMADA 3kW ENSIS 3015 RI Fiber Laser

cuts the same materials at up to 866 inches per minute, dramatically reducing cycle time for flat parts.

5. Additional in-house operations

We never trade quality for speed. Our in-house

Timesavers

machine allows us to sand, grind, and deburr prototypes efficiently, while premium operations are available to further round and smooth edges when required.

Even if you don’t need rapid prototypes today, you’ll see this same urgency reflected across all of our fabrication services.

If you can’t afford another delay and need prototypes on your desk as soon as possible,

request a quote

now and see how quickly we can move your project forward.