Last updated on May 20th, 2025 at 07:43 am

Get Rapid First Article Inspections at Approved Sheet Metal

When mass-producing a high-precision part, conducting a first article inspection (FAI) ensures that buyer dimensions remain accurate throughout the production lot. Though quality inspectors typically inspect only one to three pieces out of a batch, the process can be time-consuming if every single dimension of a part is examined.

Want to save cost and time without sacrificing quality on first article inspections?

Table of Contents

- 1 3 Tips for Smarter (and Faster) FAIs

- 2 Rapid First Article Inspections at Approved Sheet Metal

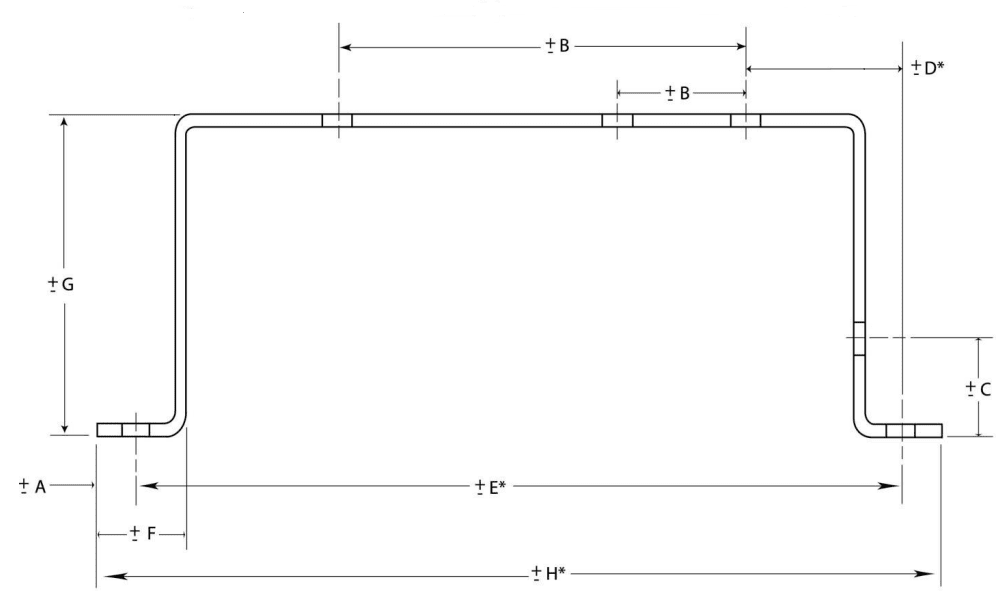

- 3 Recommended Default Sheet Metal Tolerances

- 4 First Article Inspection FAQ

- 4.0.1 What is a first article inspection (FAI), and why is it important in high-precision sheet metal part production?

- 4.0.2 How is the scope of a First Article Inspection (FAI) determined?

- 4.0.3 How can I save time and cost on first article inspections (FAIs) without compromising quality?

- 4.0.4 Are there any industry-specific standards or guidelines for conducting First Article Inspections (FAIs)?

- 4.0.5 How can I choose the right manufacturer for my precision sheet metal parts production needs?

3 Tips for Smarter (and Faster) FAIs

- Measure only what matters. Get specific on what features need to be inspected. If you submit a generic print or an approval sample print, the inspector will measure every single dimension on that map—even when they don’t have to. Identifying which specifications and features need to be assessed will save you time and money.

- Skip measuring for laser accuracy. Hole to hole laser or machine tolerances are 99% accurate, so measuring for laser correctness might not be the best use of your time. You can cut first article work in half by opting by requesting that forming dimensions are measured instead.

- Choose the right manufacturer. A good manufacturer can deliver your precision sheet metal parts on time. A great manufacturer will not only fulfill your production order, they’ll do your quality inspections as well.

Understanding the Impact of GD&T and Tight Tolerances on FAI

Many engineers specify tight tolerances or use Geometric Dimensioning & Tolerancing (GD&T) to control fit, form, and function—but these choices directly affect the cost, speed, and complexity of your First Article Inspection.

1. More Time-Intensive Measurement

Each tight tolerance requires more careful measurement using calibrated, high-precision equipment like CMMs or optical comparators. A ±0.002" tolerance, for example, takes significantly more time to inspect than a ±0.010" feature.

2. Increased Risk of Nonconformance

The tighter the tolerance, the smaller the window for acceptable variation. Even minor shifts in forming or material behavior can push a part out of spec, triggering delays or rework.

3. GD&T Adds Layers of Complexity

GD&T callouts—such as flatness, true position, or profile—require specialized tools and interpretation. These controls are vital for functional assemblies but should be applied only where truly needed.

✅ Pro Tip:

Before releasing your print for production, ask yourself:

- Is this tight tolerance functionally necessary?

- Can this GD&T callout be simplified or eliminated?

- Have I clearly labeled critical-to-function dimensions for inspection?

By prioritizing critical features and relaxing others where appropriate, you reduce inspection burden, accelerate turnaround, and still maintain the integrity of your design.

Rapid First Article Inspections at Approved Sheet Metal

When it comes to FAIs, we adopt our rapid prototyping mentality to your paperwork without the bureaucracy. You can come to us for the complete package—rapid prototyping, producing a show part, mass production, and FAIs—and we’ll always deliver top quality, on time and on budget.

ASM is certified for the following high-precision industries:

We are:

- ITAR Registered

- NADCAP-accredited

Want to work with us on your next project? Request a quote and let’s get your parts made—and inspected!