Last updated on February 14th, 2025 at 10:30 am

It’s no mystery why powder coating is such a popular choice for precision sheet metal finishing. This process is incredibly durable, provides a consistent and attractive finish, and is available in over 6,500 colors and a variety of textures.

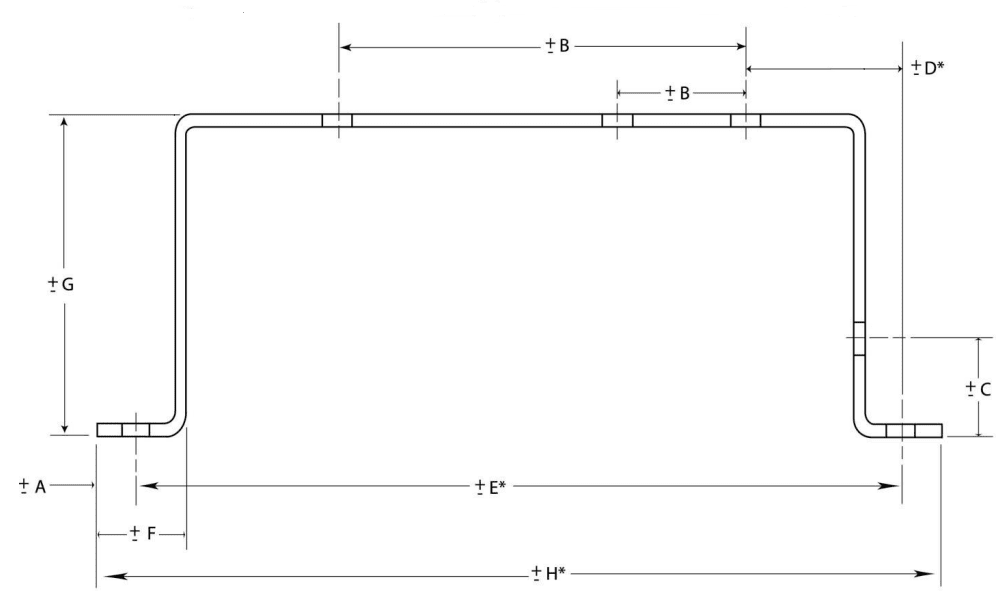

One of the only drawbacks to powder coating is that it adds a slight amount of thickness to a part. For flat parts or parts with standard tolerances, this outcome rarely presents a problem. But if you have features like cutouts and angles, it’s important to adjust your specs ahead of time to ensure that the features are still in tolerance after powder coating has been applied.

Table of Contents

- 1 How Powder Coating Adds Thickness to a Metal Fabricated Part

- 2 Material Considerations for Powder Coating

- 3 Proactive Designs Pave the Way for Optimal Powder Coating Results

- 4 Recommended Default Sheet Metal Tolerances

- 5 Sheet Metal Powder Coating Tolerance FAQ

- 5.0.1 How does powder coating affect the thickness of a metal fabricated part?

- 5.0.2 Why is it important to adjust tolerances for powder coating buildup on metal parts?

- 5.0.3 How can I anticipate and adjust for powder coating thickness when designing metal parts?

- 5.0.4 What should I consider when using textured powder coating on my metal parts?

- 5.0.5 Can Approved Sheet Metal help adjust design dimensions for powder coating, and is there a cost for this service?

How Powder Coating Adds Thickness to a Metal Fabricated Part

Powder coating involves applying dry powder (usually made out of thermoplastics) electrostatically to create a hard finish on the surface of a part.

Although the powder coats the flat surfaces of a part evenly, overspray of up to 0.002” is virtually unavoidable in features such as cutouts and corners.

This amount of added thickness may seem inconsequential, but when it accrues on two or more edges of a feature, it can quickly become problematic. Even if we mask or plug features before powder coating, some buildup is inevitable.

Adjusting tolerances to account for powder coating buildup

Adjusting your tolerances to account for the thickness powder coating adds is key to guarantee the functionality of your part.

For instance, if a hole needs to fit a peg of a particular size, the buildup from the powder coating could compromise the fit, so you’ll need to loosen the hole’s tolerances to accommodate the anticipated buildup.

It’s especially important to make these adjustments when applying a textured powder coat, which is notably thicker than a smooth powder coat.

Proactive Designs Pave the Way for Optimal Powder Coating Results

At Approved Sheet Metal, we often receive designs that include the note “all dimensions after finishing.” This instruction indicates that our team will need to adjust design dimensions to accommodate a particular finishing method, a service that our metal fabricated part shop is pleased to provide to our customers free of charge.

That said, no one knows your part as well as you do. When we loosen tolerances without understanding the full context of your part and its application, we run the risk of hindering the part’s intended function.

We’ll always make every effort to get the information we need to produce the best results. However, anticipating the need for adjustments up front and modifying your design before placing an order alleviates the risk of important details getting lost in translation.

Ready to work with a sheet metal shop that is always thinking one step ahead? Request a quote today.