Last updated on February 3rd, 2025 at 01:17 pm

Do you know which self-clinching PEM® nut has the correct shank code for your precision fabrication project?

In most of the sheet metal forming world, and here at Approved Sheet Metal, PEM® hardware is the go-to choice for self-clinching nuts. A common alternative to welding, self-clinching nuts are specialized internally threaded fasteners that provide many benefits, including increased thread strength.

When self-clinching nuts are inserted and pressed into a mounting hole in a workpiece, they displace the host material, forcing it to “cold flow” into a recess in the shank. The self-clinching nut then locks into position and becomes a permanent part of the workpiece.

Table of Contents

- 1 Why Shank Size Matters

- 2 How to Select the Shank Code for Your Precision Fabrication

- 3 How to Use Shank Codes to Choose the Right PEM® Nuts

- 4 How to Read a PEM® Spec Sheet for Shank Code Selection

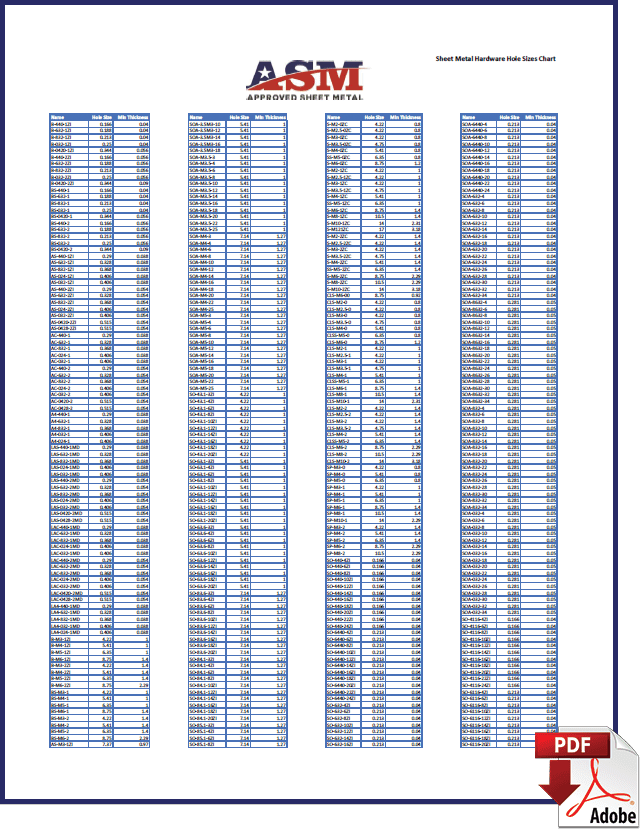

- 5 Sheet Metal Hardware Hole Sizes Chart

- 6 Sheet Metal Hardware Shank Code FAQ

- 6.0.1 How do I select the right shank code for my precision fabrication project?

- 6.0.2 What are self-clinching PEM® nuts and how do they work?

- 6.0.3 What is the significance of part numbers in self-clinching PEM® nuts?

- 6.0.4 Why does shank size matter in self-clinching nuts?

- 6.0.5 How can I use shank codes to choose the right self-clinching PEM® nuts?

Why Shank Size Matters

Shanks play an essential role in self-clinching nuts, and engineers need to choose hardware with the correct shank size for their parts to function as intended.

Shank size must be relative to material thickness.

- If the shank is too thick for the material, the hardware will stick out when the machine presses the self-clinching nut into the metal.

- If the material is thick and the shank is too thin, the self-clinching nut won’t grip the material with enough strength, and the workpiece won’t be secure.

When choosing self-clinching PEM® nuts, the length code

indicates the length of the shank. However, many engineers aren’t sure which shank code they need for their parts, causing them to select the wrong hardware for their project.

How to Select the Shank Code for Your Precision Fabrication

Shank codes are numbered 0 (if not applicable), 1, 2, or 3. Knowing which one will suit your project best can be challenging.

We’re experts at hardware selection at Approved Sheet Metal and frequently help our customers choose hardware for their sheet metal forming projects. But! We also want to empower YOU to select the proper hardware for your precision sheet metal parts.

We’ve created a handy guide that can help you identify the right shank code for your precision fabrication project.

Here's how to use this sheet metal hardware chart:

1. Identify your hardware type. Find the style of self-clinching PEM® nuts you want for your part, listed in red. If you're struggling to select a hardware type, this refresher from PEM® might make it easier:

- S/SS nuts are recommended for use in steel or aluminum sheets HRB 80 / HB 150 or less.

- CLS or CLSS nuts are recommended for use in steel or aluminum sheets HRB 70 / HB 125 or less.

- SP nuts are recommended for use in stainless steel sheets HRB 90 / HB 192 or less.

- CLA nuts are recommended for use in steel or aluminum sheets HRB 50 / HB 82 or less.

2. Choose the corresponding thread code. We've provided thread codes in standard and metric for your convenience.

3. Find the accompanying minimum sheet thickness of your material.

4. Note the shank code that aligns with your factors: hardware type, thread code, and sheet thickness.

For example, if your material is 0.040" thick and you want an M3 nut, which shank code do you choose? Answer: 1! If your material is 0.074" thick and you want an M3 nut, you’d select a 2.

How to Use Shank Codes to Choose the Right PEM® Nuts

Once you know which shank code you need for your custom sheet metal parts, you'll be able to pick the correct self-clinching PEM® nuts.

All PEM® self-clinching nuts have part numbers, and strings of codes representing this information:

- Type: S, SS, CL, CLS, S, or CL

- Material Code: S, P, or A

- Thread Size Code: Can vary; 256, 348, 440, 632, etc.

- Shank Code: 0, 1, 2, 3 (zero indicates no shank)

- Finish: Can vary; Z1, CU, etc., or blank if not applicable

The part numbers follow this formula: Type and Material Code–Thread Code—Shank Code and Finish

For example, the part number CLA-632-2 can be broken down like this:

- Type: CL

- Material Code: A

- Thread Size Code: 632

- Shank Code: 2

- Finish: None

Let's look at another one. The part number CLS-440-1 can be broken down like this:

- Type: CL

- Material Code: S

- Thread Size: 440

- Shank Code: 1

- Finish: None

How to Read a PEM® Spec Sheet for Shank Code Selection

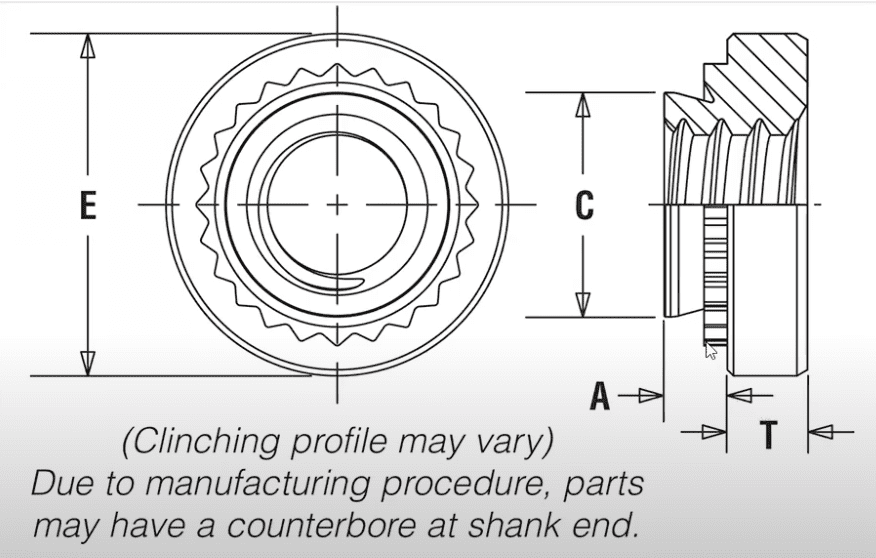

When selecting the right self-clinching PEM® nut for your sheet metal project, understanding how to read a PEM® spec sheet can save time and prevent costly mistakes. These spec sheets provide essential data to help engineers choose the correct shank code based on material thickness, thread size, and fastener type. Here’s a breakdown of what to look for:

1. Identify the Hardware Type

PEM® self-clinching nuts come in various styles, each designed for specific material hardness levels and applications. Look for the Type designation (e.g., S, SS, CLS, CLSS, SP, CLA) to ensure compatibility with your material.

2. Locate the Minimum Sheet Thickness Requirement

Every PEM® nut has a minimum sheet thickness listed in the spec sheet. If your material is thinner than the specified value, the nut will not clinch properly, leading to poor retention or complete failure.

3. Find the Recommended Hole Size

PEM® nuts require a precise hole diameter for proper installation. The spec sheet provides the correct hole size based on the selected nut type and thread size. Even slight variations from these values can result in weak retention or improper seating.

4. Determine the Correct Shank Code

The shank code (0, 1, 2, or 3) is directly related to the sheet thickness and determines how well the nut will embed into the material. The spec sheet provides a table that correlates:

- Material thickness → Minimum and maximum values for each shank code.

- Shank length → Ensuring the nut is properly seated without protruding excessively.

5. Review Torque and Push-Out Resistance Data

PEM® spec sheets include performance metrics such as torque-out resistance and push-out force. These values help engineers understand how well the fastener will hold up under real-world conditions.

6. Check for Special Considerations (Finish, Coatings, and Variations)

Some self-clinching nuts include additional options such as:

- Finish codes (e.g., Z1 for zinc plating, CU for copper coatings).

- Variations in thread types (metric vs. imperial).

- Special designs for unique applications (e.g., floating nuts, flush-mount styles).

Now you’re ready to select the proper hardware for your precision fabrication projects every time! However, as always, our team is more than happy to assist you, so if you want an expert opinion to ensure the success of your parts, just ask.

Request a quote to get started with Approved Sheet Metal today.