Last updated on March 24th, 2025 at 09:39 am

Did you know that the design for your formed precision sheet metal part might not be manufacturable at many metal fabrication shops?

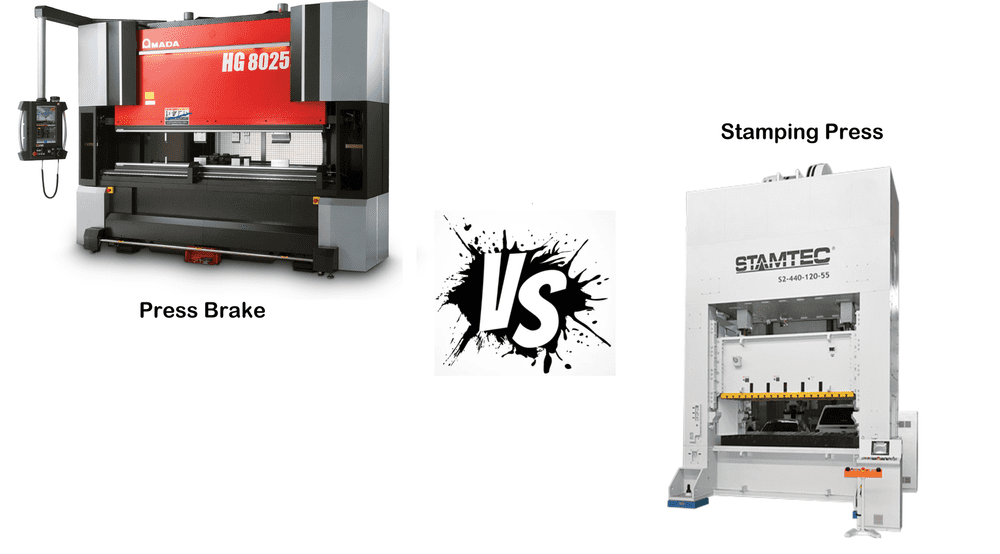

Most shops rely on standard press brake tooling to efficiently fabricate formed sheet metal parts, and they may no-quote parts that they can’t easily manufacture.

Most shops rely on standard press brake tooling to efficiently fabricate formed sheet metal parts, and they may no-quote parts that they can’t easily manufacture.

But at Approved Sheet Metal, we’re committed to getting you the sheet metal parts you need, and our forming experts can take your part design from “no-quote” to “no problem.”

Table of Contents

- 1 Standard Press Brake Tooling Examples

- 2 Examples of Non-Manufacturable Formed Parts

- 3 3 Options for Projects Requiring Non-Standard Press Brake Tooling

- 4 Example of an Updated Design for a Formed Part

- 5 Material Considerations in Forming

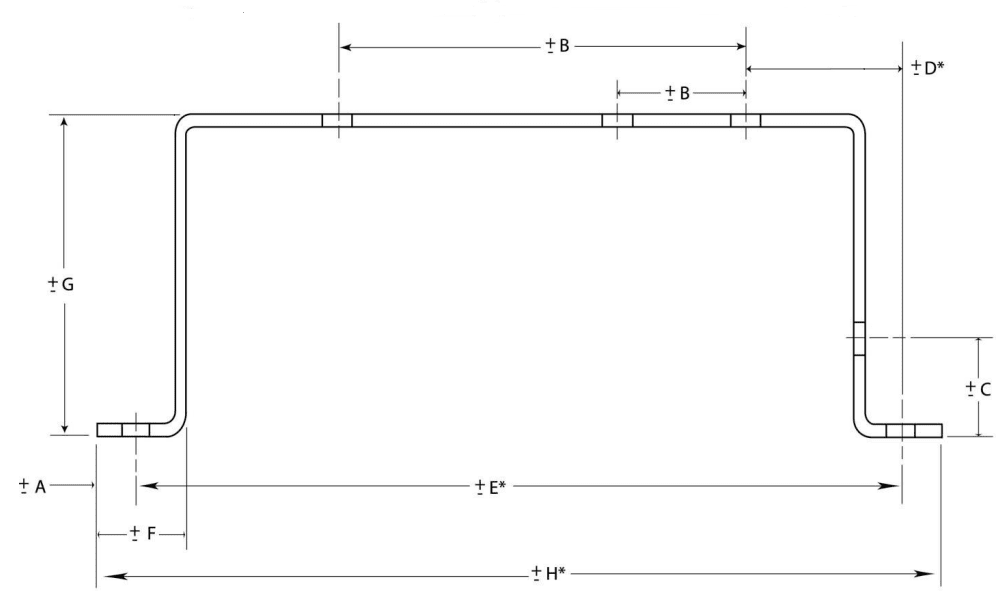

- 6 Recommended Default Sheet Metal Tolerances

- 7 Standard Press Brake Tooling FAQ

- 7.0.1 Why might the design for my precision sheet metal part not be manufacturable at many metal fabrication shops?

- 7.0.2 What kind of standard press brake tooling is available for forming sheet metal parts?

- 7.0.3 What options are available for projects that require non-standard press brake tooling?

- 7.0.4 Can Approved Sheet Metal help me update my design to make it manufacturable with standard tooling?

- 7.0.5 How can I get assistance from Approved Sheet Metal for my precision sheet metal parts?

Standard Press Brake Tooling Examples

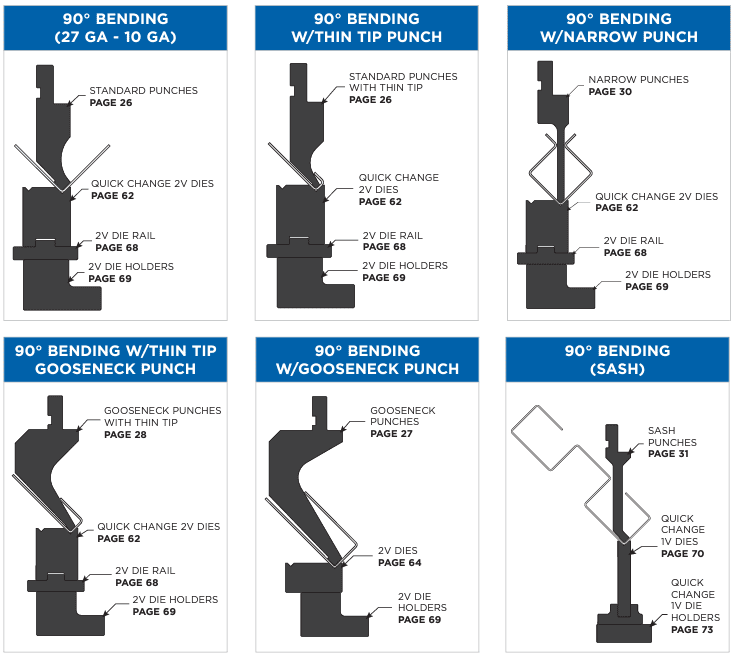

The standard press brake tooling we have is consistent with what you’d find at any sheet metal shop:

The standard press brake tooling we have is consistent with what you’d find at any sheet metal shop:

- 90-degree bending for 27-10 gauge

- 90-degree bending with thin tip punch

- 90-degree bending with narrow punch

- 90-degree bending with thin tip gooseneck punch

- 90-degree bending with gooseneck punch

- 90-degree bending (sash)

We can also use custom offset tooling for when the offset height and angle are equally important for the part. (If the offset height is more important than the angle, then we’ll likely create a “lazy offset” instead.) For parts requiring hemming, we have hem tooling.

We can form large radii in one hit or rely on bump-forming, as shown here.

Finally, we have gusset tooling for adding gussets to bent sheet metal parts.

Examples of Non-Manufacturable Formed Parts

Sometimes we receive designs for parts that we can’t form using standard tools, posing challenges that can cost customers time and money. For example, when we see a part design with rounded radii, we know that our in-house tooling won’t get the job done.

Sometimes we receive designs for parts that we can’t form using standard tools, posing challenges that can cost customers time and money. For example, when we see a part design with rounded radii, we know that our in-house tooling won’t get the job done.

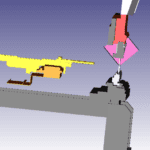

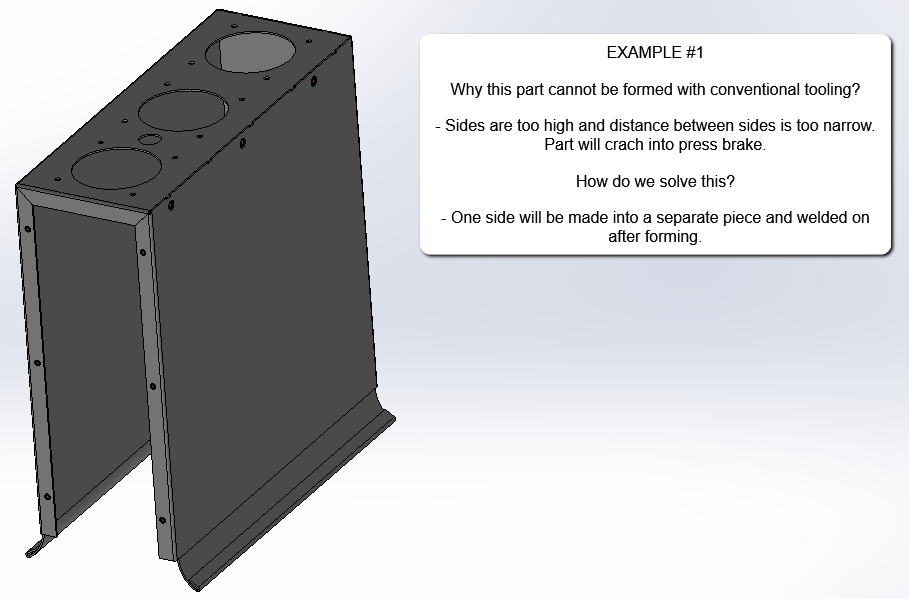

Deep boxes can also be impossible to form using conventional tooling. In this example, the sides are too high and the distance between the sides is too narrow, which would cause the part to crash into the press brake.

3 Options for Projects Requiring Non-Standard Press Brake Tooling

So, what happens when we get an RFQ for a part that we can’t make with standard press brake tooling? We find a solution to avoid the dreaded no-quote. Here are three pathways forward at ASM:

Custom tooling

While custom tooling is an option, we consider it almost as bad as no-quoting. Why? Custom tooling adds considerable cost and time to a project, which is hard to justify for prototypes or low-volume parts. Our team will always try to find alternative solutions before suggesting custom tooling. But if you decide that’s the right path, we’ll support your plan and work with you to get the proper tooling for your project.

Cut and weld

We’re experts at cutting and welding sheet metal parts and offer various in-house welding capabilities, including MIG, TIG, and spot welding. When a sheet metal part is too big for our standard equipment and tooling, we can separate it and weld the pieces together into a final part.

Update the design

The most efficient solution is often to update the design so the part can be made using standard tooling. You may need to sacrifice certain aesthetic preferences, such as rounded features. But if you have some degree of flexibility in your design, minor changes can save you time and money.

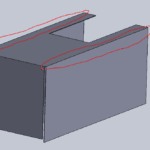

Example of an Updated Design for a Formed Part

We love to help our customers improve their designs and are always happy to collaborate with you.

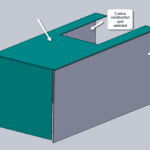

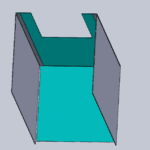

For example, this project posed a small challenge: the part walls exceeded our equipment depth capacity, which would cause the part to crash into the press brake during the bending process. We came up with two alternative options.

Material Considerations in Forming

Material selection for sheet metal fabrication significantly impacts formability, tooling choices, and overall part performance. Engineers must account for factors like material hardness, thickness, and elongation properties to ensure parts can be efficiently formed without defects.

1. Common Sheet Metal Materials and Their Formability

| Material | Formability | Key Considerations |

|---|---|---|

| Aluminum (5052, 6061) | Good (5052), Poor (6061) | 6061 is prone to cracking when bent; 5052 is preferred for formed parts. |

| Mild Steel (CRS, HRS) | Excellent | Can be easily formed but may require additional corrosion protection. |

| Stainless Steel (304, 316) | Moderate to Poor | High springback; requires increased bend radii and force. |

| Copper/Brass | Excellent | Soft and ductile; often used in electrical applications. |

2. Key Material Properties Affecting Forming

- Ductility & Elongation: Determines how much a material can be stretched or bent without cracking.

- Yield Strength: Higher strength materials require more force to form and may exhibit greater springback.

- Thickness: Thicker materials require larger bend radii and may need specialized tooling.

- Grain Direction: Forming perpendicular to the grain structure reduces cracking risk, especially in stainless steel.

3. Strategies for Improved Formability

- Choose the Right Alloy: For aluminum parts that require forming, 5052 is a better choice than 6061.

- Increase Bend Radii: Tight bends increase the risk of cracking, especially in high-strength materials.

- Annealing or Stress-Relieving: Some materials (e.g., stainless steel) benefit from heat treatment before forming.

- Utilize Pre-Finished Materials: Pre-anodized or pre-plated materials can reduce post-processing steps.

Whether you need custom tooling, cutting and welding, or design updates, our team is here to help you get your sheet metal parts fast. Our goal is to maintain your design intent while efficiently moving your part through our shop.

Let us show you what our team of sheet metal fabrication experts can do for you. Request a quote for your precision sheet metal parts today.