Last updated on February 2nd, 2026 at 02:35 pm

At Approved Sheet Metal, we're all about giving our customers the best possible experience and the highest quality custom fabrications. Sometimes, that involves making recommendations, or “upgrades”, that help our customers save time, reduce costs, improve part performance, or all of the above.

Each project is unique, but there are a few common upgrades we recommend that consistently improve quality, shorten lead times, and simplify production. Let’s take a closer look at three of them.

Table of Contents

- 1 Upgrade Your Custom Fabrications to Improve Cost, Quality, and Lead Time

- 2 6 Tips for Designing Powder Coated Sheet Metal Parts

- 3 Optimize Cost and Lead Time for Custom Fabrications FAQ

- 3.0.1 Why should I consider using sheet metal instead of tubing for structural frames in my project?

- 3.0.2 What are the advantages of replacing welding with mechanical fasteners in custom fabrications?

- 3.0.3 When should I opt for powder coating instead of wet paint for finishing custom fabrications?

- 3.0.4 Will choosing mechanical fasteners over welding compromise the strength of my custom fabrications?

- 3.0.5 How does opting for powder coating enhance the durability of custom fabrications compared to wet paint?

Upgrade Your Custom Fabrications to Improve Cost, Quality, and Lead Time

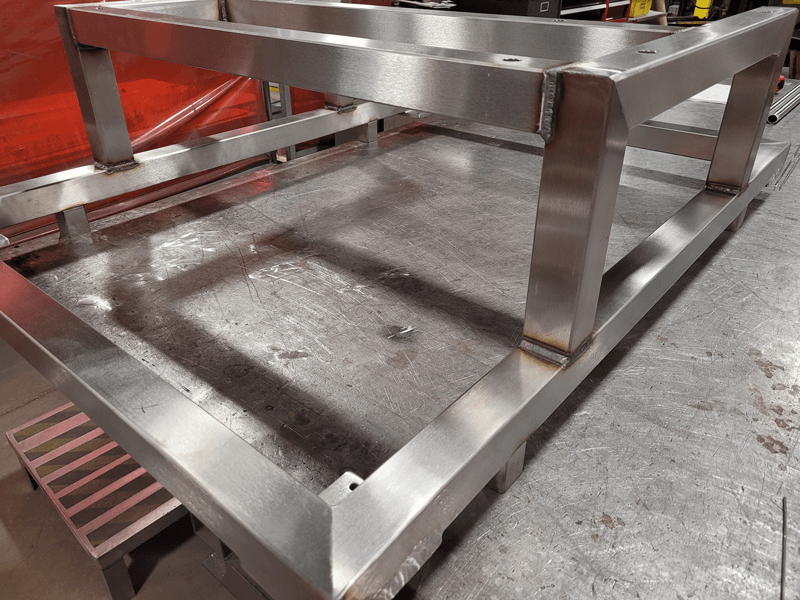

1. Use sheet metal instead of tubing for structural frames

When customers need structural frames, tubing is often the default assumption. But tubing typically requires extensive saw cutting, which is slower and less precise than modern sheet metal processes and can compromise frame consistency.

A better option is to fabricate the frames from sheet metal instead of using tubing. In our shop, we can use our new high-power fiber laser to cut the frames and achieve greater precision. Laser cutting requires less labor than saw cutting, lowering costs and reducing lead times.

In terms of material sourcing, sheet metal is often significantly more accessible than tubing, which means we can get your project started ASAP.

2. Replace welding with mechanical fasteners

Welding is a great option for many custom fabrications: it’s ideal for watertight applications or for achieving a smooth cosmetic appearance. However, for many assemblies, mechanical fasteners such as rivets and rivnuts can reduce lead time, simplify production, and improve serviceability.

Rivnuts add load-bearing threads to thin sheet metal parts, allowing them to hold up to heavier external forces than welded parts could. And for applications like chassis, furniture, and bicycles, fasteners allow components to be routinely disassembled and reassembled. That’s simply not possible with welded parts.

3. Use powder coating instead of wet paint

Using wet paint to finish custom fabrications works well for specific applications, especially those requiring substantial corrosion resistance or specialized coating requirements. However, in many cases, powder coating is the more efficient and durable option.

When we paint parts, we have to prime the surface, then wait for it to dry. Apply a coat of paint; wait for it to dry. And so on. Depending on the number of coats, a two-week wet paint job might take just one week with powder coating. Powder coating is also more durable than wet paint and less prone to cracking and shattering.

As you begin planning your next sheet metal fab project, consider making one or more of these upgrades. We’re always here to help advise on what’s best for your unique parts. Request a quote today!