Last updated on February 4th, 2026 at 09:14 am

At Approved Sheet Metal, we deliver excellence in sheet metal fabrication. And providing you with the highest-quality service includes helping you choose the best finishing method for your parts.

with the highest-quality service includes helping you choose the best finishing method for your parts.

Powder coated sheet metal parts are durable, attractive, and the method is versatile which works well for many applications. In our shop, we powder coat aluminum, steel, and stainless steel parts with fantastic results.

With over two decades of experience in powder coating, we’ve learned that a little bit of foresight yields superior outcomes. Here are our top tips for powder coated sheet metal parts.

Table of Contents

- 1 1. Make Sure Your Part Can “Hang”

- 2 2. Account for Buildup

- 3 3. Clarify Specific Colors, Textures, and Sheens

- 4 4. Request Pre-Treatments When Needed

- 5 5. Powder Coating Impact on Threads and Fasteners

- 6 6. Select a Single Color

- 7 Recommended Default Sheet Metal Tolerances

- 8 Powder Coated Sheet Metal FAQ

- 8.0.1 What materials can you powder coat, and what are the benefits of powder coating?

- 8.0.2 How can I prepare my parts for powder coating?

- 8.0.3 How does powder coating affect part dimensions, and how can I specify colors and textures?

- 8.0.4 When should I request pre-treatments before powder coating?

- 8.0.5 Can hardware be added before or after powder coating?

1. Make Sure Your Part Can “Hang”

When we powder coat your parts, we hang them on a rack, ensuring that all surfaces are exposed to allow for a uniform coat. There are a few different ways to prepare parts for hanging:

Existing holes

Many parts come to us with holes already drilled for hardware insertion. We can use the same holes to hang the parts for powder coating.

New holes

If your part requires powder coating and your design doesn’t already have holes, we recommend designing a 0.125” diameter hole in an inconspicuous area so that we can hang your part.

Break-off tabs or clips

It’s important to note that any holes added to a part won’t be plugged after powder coating. If a small but permanent hole isn’t an option, you can add break-off tabs with holes that can be removed after powder coating. Alternatively, if your part is small (6”-8”), it can hang from clips attached to the rack.

But keep in mind that with either of these approaches, some final touch-up will be required, which may increase your costs.

2. Account for Buildup

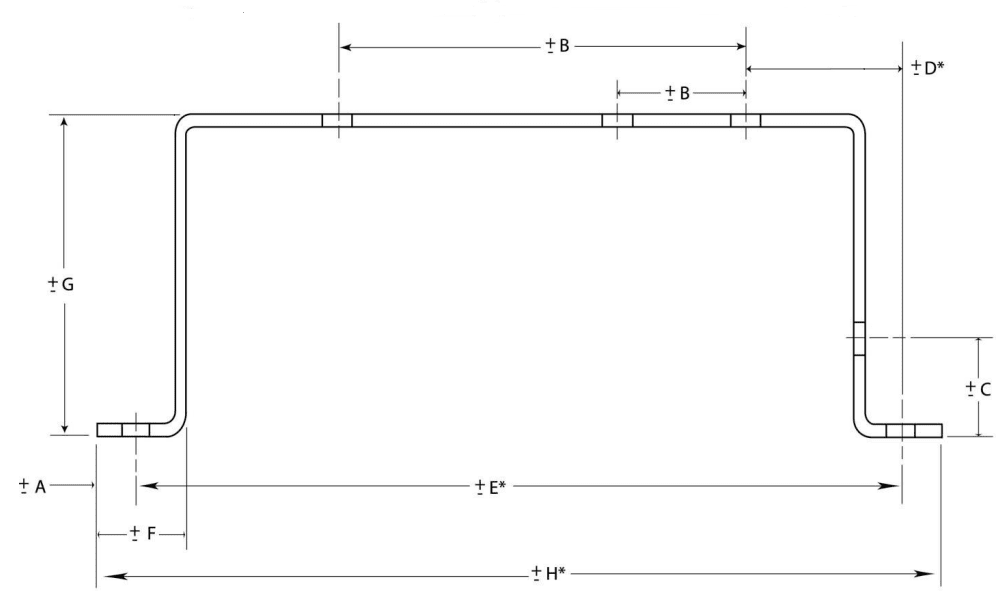

Powder coating adds approximately 0.003”-0.004” of buildup to a part, and it’s important to account for this buildup in your design.

Designs with tight hole tolerances, in particular, may require post-powder coating operations to open up the holes.

3. Clarify Specific Colors, Textures, and Sheens

The wide variety of powder coat options is one reason it’s such a popular finishing method. But the same color一even something as seemingly straightforward as “powder coat black”一can vary considerably among powder coat brands.

Calling out the exact RAL (color code), texture, and gloss for a specific brand is the

best way to ensure that your part will have the final appearance you desire. Note that although a RAL describes a unique color, the color may still vary slightly from one brand to another.

It’s also important to remember that if you’ve used a powder coat from a particular brand for your prototype, you should use the same powder coat during production to ensure consistency.

Finally, keep in mind that not all powder coat varieties are readily available, and some may have a high per-pound cost with a minimum buy that exceeds your needs. You may want to compare the availability and cost of a few types before making your final decision.

Locating color information

So, where can you find specific color information to share with your finisher?

Browsing color palettes on the websites of suppliers such as Cardinal Paint and Sherwin-Williams is a great way to start. Be aware, however, that colors may appear different online than in real life. To verify that you’re choosing the right color for your powder coated sheet metal parts, request physical samples from the supplier.

We are also happy to send samples of our house colors for your review. Complete our contact form for details!

4. Request Pre-Treatments When Needed

Treating parts with chromate or zinc before powder coating provides enhanced corrosion resistance, which may be necessary for parts that will be used in harsh environments or require electrical conductivity.

These treatments are added only upon request, so be sure to call them out if needed.

5. Powder Coating Impact on Threads and Fasteners

Powder coating creates a durable and protective finish, but it can pose challenges when applied to threaded holes, bolts, and fasteners. The coating’s thickness (typically 0.003”–0.004”) can interfere with proper fit and function, making assembly difficult or even impossible. Here’s how to avoid these common issues and ensure a smooth manufacturing process.

1. Masking Threads Before Coating

One of the best ways to prevent powder buildup in threaded holes or on fasteners is through masking. Options include:

- Silicone Plugs: Reusable, heat-resistant plugs protect internal threads and can be easily removed after curing.

- High-Temperature Tape: Applied over external threads or areas needing protection, this tape peels off cleanly after the powder coating process.

- Custom Threaded Inserts: Temporary inserts can be placed in threaded holes before coating and removed afterward to maintain clean threads.

If your part requires functional threads, be sure to specify which holes or fastener locations should be masked before coating.

2. Post-Coating Thread Tapping

If masking isn’t an option, another approach is post-process thread tapping. After powder coating, holes can be re-tapped to remove excess coating and restore proper threading. However, this adds extra labor and cost, and in some cases, the powder-coated edges of the threads may become weak or prone to chipping.

3. Using Pre-Installed Fasteners

For assemblies requiring powder-coated fasteners, consider using pre-installed fasteners that can remain in place during coating. This allows the fastener heads to be coated while protecting the threads. However, if fasteners need to be removed for final assembly, this may not be a viable option.

4. Alternative Solutions for Threaded Components

In some cases, a better solution is to use threaded inserts or studs that are installed after powder coating. This ensures strong, functional threads without additional machining. If your part requires tight-threaded tolerances, consider adding PEM® inserts or other fastening solutions after finishing.

By planning for powder coating’s impact on threads and fasteners, you can avoid assembly headaches, reduce rework, and ensure a perfect fit for your finished product. If you’re unsure about the best approach for your design, our team at ASM is happy to advise!

6. Select a Single Color

While applying multiple colors of powder coat to a single part is technically possible, doing so can be needlessly difficult, risky, and expensive. For example, the part can become scorched or incur unwanted paint residue from masking.

If you need a multi-colored part, wet paint is a preferable choice.

Why Choose Approved Sheet Metal for Powder Coated Sheet Metal Parts?

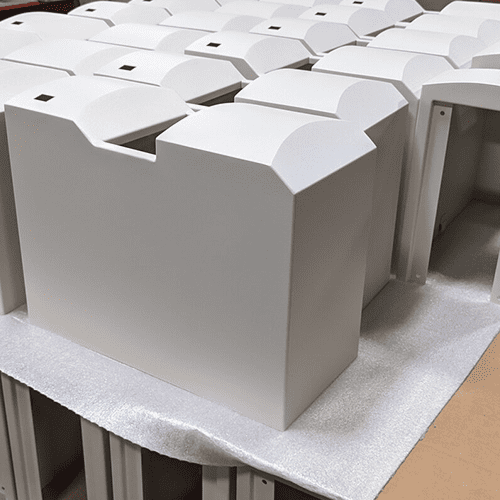

At Approved Sheet Metal, we provide sheet metal fabrication services and powder coating services under one roof, giving us full control of the entire manufacturing process and ensuring that you get high-quality parts quickly and cost-effectively. In fact, our in-house powder coating services save you about three days in lead time!

With robust capabilities for sheet metal finishing, we can fulfill your powder coating needs. Request a quote!