Last updated on May 23rd, 2025 at 09:37 am

Sheet metal fabrication shops are in a never-ending sprint toward automation. To remain competitive in this industry, customers expect sheet metal fabricators to offer quick delivery, rapid prototyping, small batch quantity production, and flexible scheduling.

At Approved Sheet Metal, we’re constantly striving to be better than yesterday—and that means investing in new equipment to streamline our processes for better and faster delivery.

Recently, we added an AMADA 3kW ENSIS 3015 RI Fiber Laser to our impressive list of equipment. We’re excited to tell you all about it!

Table of Contents

- 1 What Is a Fiber Laser?

- 2 7 Benefits of Approved Sheet Metal’s High-Power Fiber Laser

- 3 Design for Laser Cutting (DfLC) Guidelines

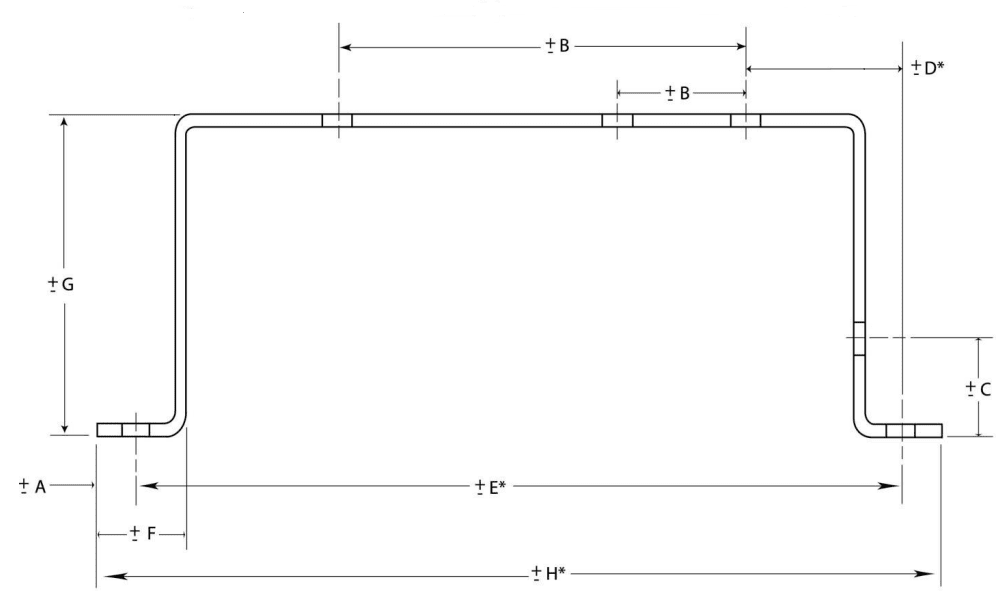

- 4 Recommended Default Sheet Metal Tolerances

- 5 Fiber Laser Advantages for Sheet Metal Fab FAQ

- 5.0.1 What is a Fiber Laser and How Does It Differ from CO2 Laser Cutting?

- 5.0.2 What Are the Benefits of a High-Power Fiber Laser?

- 5.0.3 How Does a Fiber Laser Enhance Design Freedom?

- 5.0.4 What Makes a Fiber Laser More Efficient and Automated?

- 5.0.5 How Does A Fiber Laser Improve Material Flexibility and Edge Quality?

What Is a Fiber Laser?

Laser technology entered the metal cutting industry with the arrival of CO2 laser cutting machines. Carbon dioxide lasers were the first to use directed beams of infrared light to heat and cut through materials like paper, wood, plastic, and metal.

Soon after the CO2 laser cutting machine came around, technological advancements led to the development of a faster, more energy-efficient machine: the fiber laser.

Rather than using gas to create infrared light, fiber lasers use rare-earth fibers to produce a shorter, more precise laser beam offering higher power and accuracy per square millimeter.

7 Benefits of Approved Sheet Metal’s High-Power Fiber Laser

Our AMADA 3kW ENSIS 3015 RI Fiber Laser is pretty impressive if we do say so ourselves. But don’t just take our word for it. Check out what this machine has to offer:

- Blazing fast speeds. Our CO2 laser cut .059” aluminum or steel at just 60 inches per minute, but our fiber laser is capable of cutting an impressive 866 inches per minute! Now we can offer even faster same day rush service for flat sheet metal parts and complete production parts quicker than ever before.

- Design freedom. There’s no reason to feel limited when designing your part. Our fiber laser can fabricate holes, contours, flanges, threads, even delicate curve and line etchings on sheet metal—all without the heat distortion caused by CO2 laser cutters. The intelligent software moves the laser strategically to avoid overheating one area of the material.

- Automatic features. Equipped with a hyper intelligent computer, our fiber laser features an Automatic Nozzle Changer that can clean and select an appropriate tool based on the cut currently being used. Another great feature is the Part Sorting Robot, a fully automated solution that can sort and deposit parts into specific bins, remove the remaining skeleton of the workpiece from the main cutting space, and replace it with a new piece of sheet metal. Now that’s automation at its finest!

- Cut processing monitoring system. Designed to work reliably and efficiently, our fiber laser can detect when a part hasn’t been machined correctly. If a workpiece misses a cut, for example, the monitoring system will send out an alarm until the issue is resolved. This incredible detection system produces high-precision parts and saves time on costly rework.

- Material flexibility. With our new fiber laser, we can machine a wide range of materials including steel, copper, and brass. We can also cut much thicker materials. Previously, we could only cut up to ⅛” stainless steel, but now we can cut up to ½” stainless steel and aluminum. That’s 4 times the material thickness a CO2 laser cutter can handle!

- Better edge quality. Our fiber laser has such a precise native cut that it virtually eliminates the need for deburring, reducing cost and lead time for our customers. The machine’s end light system allows our operators to control the shape of the laser so they can cut nicer, sharper, crisper edges that nail those tight tolerances.

- Lower cost and energy consumption. Because a fiber laser doesn’t need gas to operate, it has lower energy and maintenance demands. The total operational cost of a fiber laser is half the amount of a CO2 laser cutter!

Design for Laser Cutting (DfLC) Guidelines

When engineering a part for high-power fiber laser cutting, following Design for Laser Cutting (DfLC) principles ensures higher precision, lower cost, and fewer post-processing requirements. Here are key design guidelines mechanical engineers should keep in mind when preparing parts for laser fabrication:

1. Maintain Proper Minimum Feature Sizes

- Hole diameter: Avoid holes smaller than the material thickness. As a rule of thumb, the minimum hole size should be at least 1.2x the material thickness.

- Kerf width: Expect a kerf (cut width) of 0.006"–0.012" depending on material and thickness. Design tight features accordingly.

2. Corner Radii and Internal Sharp Edges

- Sharp 90° internal corners can cause thermal stress and cracking. Instead, use a minimum internal radius equal to the material thickness to distribute heat more evenly and reduce tool wear.

3. Feature Spacing

- Keep small cutouts and holes at least 2–3 times the material thickness apart to avoid warping or part separation during the cut.

- Ensure tabs or connecting webs have enough strength to hold nested parts in place during the laser process.

4. Avoid Heat Accumulation Zones

- For complex patterns or dense arrays of small holes, spread features out to prevent localized heat buildup, which can cause material distortion.

- Design parts with cut sequencing in mind to allow the laser to cool between high-density regions.

5. Tapped Holes and Hardware Considerations

- Don't laser-cut threads. Instead, laser the clearance hole and specify threading or PEM hardware installation as a secondary operation.

- Use standard hole sizes that match your fasteners or inserts to streamline downstream operations.

6. Optimize for Nesting and Material Yield

- Design flat parts with consistent margins to maximize sheet utilization during nesting.

- Avoid part geometries that leave narrow strips or irregular islands of scrap, which are difficult to manage and increase material waste.

Check out our AMADA 3kW ENSIS 3015 RI Fiber Laser in action:

At Approved Sheet Metal, we’re committed to delivering top-quality parts to your door at record-breaking speed. We can’t wait to show you everything our fiber laser can do. Give us a shot on your next project!