Last updated on February 9th, 2026 at 08:59 am

When you’re assembling a series of industrial sheet metal components, it’s important to use fasteners that provide strong, load-bearing threads and will not easily strip out under pressure.

Screws, bolts, and rivets are good examples of common mechanical fasteners that can secure components with substantial holding power.

But what if your design requires a fastening system that allows components to be attached, removed, and reinstalled over time?

Rivnuts are a strong, durable, and removable solution for assembling and disassembling custom sheet metal components efficiently.

Table of Contents

- 1 The Benefits of Using Rivnuts for Stronger, Removable Fittings

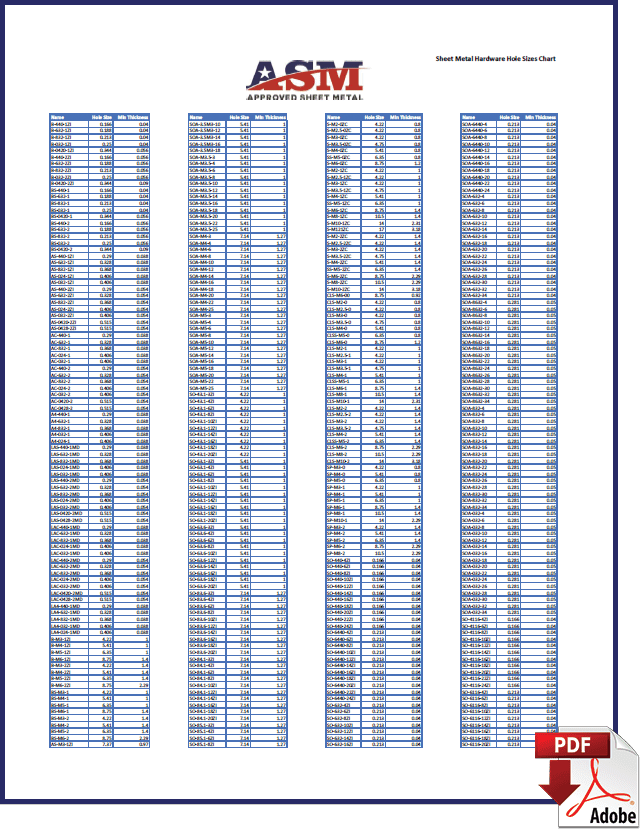

- 2 Sheet Metal Hardware Hole Sizes Chart

- 3 Sheet Metal Rivnut FAQ

- 3.0.1 What are rivnuts and how do they work?

- 3.0.2 What are the benefits of using rivnuts in sheet metal assemblies?

- 3.0.3 Can rivnuts be used in applications with thin or weak sheet metal?

- 3.0.4 Are rivnuts suitable for hard-to-reach areas in assemblies?

- 3.0.5 Are rivnuts installation-friendly and compatible with various materials?

The Benefits of Using Rivnuts for Stronger, Removable Fittings

Rivnuts, also commonly referred to as rivet-nuts, are hardware components used to fasten two pieces of sheet metal together.

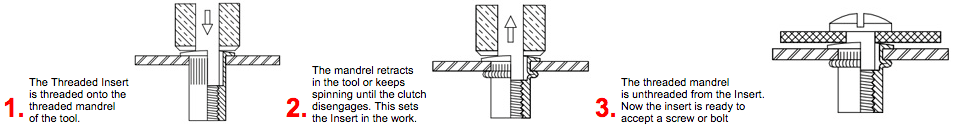

A rivnut is tubular in shape. Much like a standard rivet, it is installed into a pre-drilled hole and set in place either by hand or with pneumatic or hydropneumatic tools. Once installed, it creates a permanent internal thread in the sheet metal. With the correct bolt size, components can be securely fastened and unfastened as needed.

There are many benefits to using rivnuts in sheet metal assemblies:

- Adding strong load-bearing threads to thin or weak sheet metal parts.

Rivnuts allow threads to be added to panels that are normally too thin or weak for tapping. During installation, the rivnut collapses on the back side of the panel, forming a strong mechanical anchor that is far more durable than cut threads and resistant to pull-out.

- Access to blind locations.

Rivnuts are blind threaded inserts, meaning they can be installed securely from one side of a workpiece. This makes them ideal for applications such as tubular frames [link to New Capability: Stainless Steel Tubular Frames for the Medical Industry] and other assemblies where internal access is limited or impossible.

- Assembling and disassembling components with ease.

The ability to take apart and reattach assemblies is critical for many applications, including chassis, furniture, vehicle interiors, bicycles, and solar panel systems. Rivnuts provide a practical solution that supports repeated assembly without compromising strength.

- Scratch and damage-free installations.

Rivnut installation does not require heat, tapping, or electrical current, which helps reduce the risk of surface damage and distortion. Because no heat is applied, rivnuts can also be installed in a wide range of materials, including steel, plastic, and fiberglass.

Rivnuts are available in many shapes, sizes, and styles, including flathead, ribbed, and countersunk designs. The simplest way to include rivnuts in a sheet metal assembly is to call them out directly in the drawing or CAD model. Here’s a handy chart for guidance.

Material Compatibility and Selection

Choosing the correct rivnut material is critical for compatibility with the base sheet metal and the performance requirements of the application. Key considerations include:

- Material Types: Rivnuts are commonly available in steel, stainless steel, and aluminum. Material selection depends on corrosion resistance, strength requirements, and compatibility with the sheet material. Stainless steel rivnuts are often selected for applications exposed to harsh or corrosive environments.

- Corrosion Resistance: Rivnut material and coating should be selected based on the corrosion resistance required for the operating environment.

- Surface Treatment: Steel rivnuts are frequently zinc plated to improve corrosion resistance. The standard supplied surface treatment is 8µ zinc plated, chrome-free iridescent passivated.

Design Considerations and Limitations

Proper design and installation are essential to ensure rivnuts perform reliably over the life of the assembly:

- Hole Preparation: Hole dimensions must match the rivnut specifications. Accurate hole diameter or across-the-flats dimensions are required to prevent spinning or improper setting.

- Installation Access: Rivnuts can be installed from one side of a workpiece, making them ideal for enclosed structures such as tubular frames and boxed assemblies.

- Load Requirements: Rivnut selection should be based on expected loads. For example, a properly installed 1/4-20 rivnut in 0.030 rolled steel has a pull-out strength of approximately 480 pounds. Using multiple rivnuts provides additional safety margin for static and dynamic loads.

- Installation Tools: ASM uses appropriate installation tools to ensure rivnuts are set correctly. Improper installation can reduce load capacity or cause loosening over time. Correct mandrel length and high-quality socket-head cap screws are recommended.

- Material Thickness: Sheet thickness must fall within the rivnut grip range. Selecting the correct rivnut length based on material thickness is critical for secure fastening. When multiple options fall within tolerance, shorter rivnuts are often preferred for harder materials.

When you work with our sheet metal fabrication shop, we can source and install rivnuts as part of your complete assembly process. Our team has extensive experience selecting and installing rivnuts to ensure strength, repeatability, and long-term reliability. Request a quote today.