Last updated on January 22nd, 2026 at 08:41 am

Sharp edges, burrs, and flimsy flanges are common issues in sheet metal parts. In many cases, these problems can be solved with proper hemming.

In sheet metal fabrication, hemming involves folding material back onto itself to reinforce an edge, improve safety, or achieve a cleaner appearance. Hems are commonly used to eliminate exposed edges, add stiffness, and improve part durability.

Much like the familiar sewing technique that prevents the fabric from becoming frayed at the edges, hemming in sheet metal fabrication consists of folding a piece of metal over onto itself. Hemming is commonly used to conceal an edge or a burr, to provide added strength, or to achieve a smooth aesthetic appearance.

At Approved Sheet Metal, we rely on our advanced press brake for all custom sheet metal hemming. Here’s a look at the four most common types of sheet metal hems that we use:

Table of Contents

- 1

- 2 When to apply the 4 Common Types of Sheet Metal Hems to your Design

- 3 Sheet Metal Part Design for Manufacturing Tip

- 4 Types of Sheet Metal Hems FAQ

- 4.0.1 What is hemming in sheet metal fabrication?

- 4.0.2 What are the four most common types of sheet metal hems used by Approved Sheet Metal?

- 4.0.3 What are the material limitations for closed hems?

- 4.0.4 When is an open hem used in sheet metal fabrication?

- 4.0.5 What is the purpose of a rolled hem in sheet metal fabrication?

When to apply the 4 Common Types of Sheet Metal Hems to your Design

1. Closed hem.

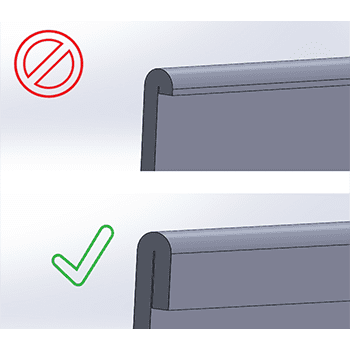

Also known as a crushed hem, a closed hem is completely flush (as opposed to an open hem, which allows for a bit of space in the bend).

Closed hems are the most popular type of hem because they’re so easy to make: the sheet metal is simply flattened onto itself. There are, however, some material limitations.

This type of hem works best with material thicknesses of .040”-.125”. We try to avoid forming material over .125” because the sheet metal is likely to fracture. The flat length of the hem must also be a minimum of 4x the material thickness so that it doesn’t break.

We shape our closed hems by forming sheet metal to 145 degrees, then flattening the material onto itself with a press brake. As a rule, we don’t use closed hems for aluminum, as this type of material is highly susceptible to cracks and fractures.

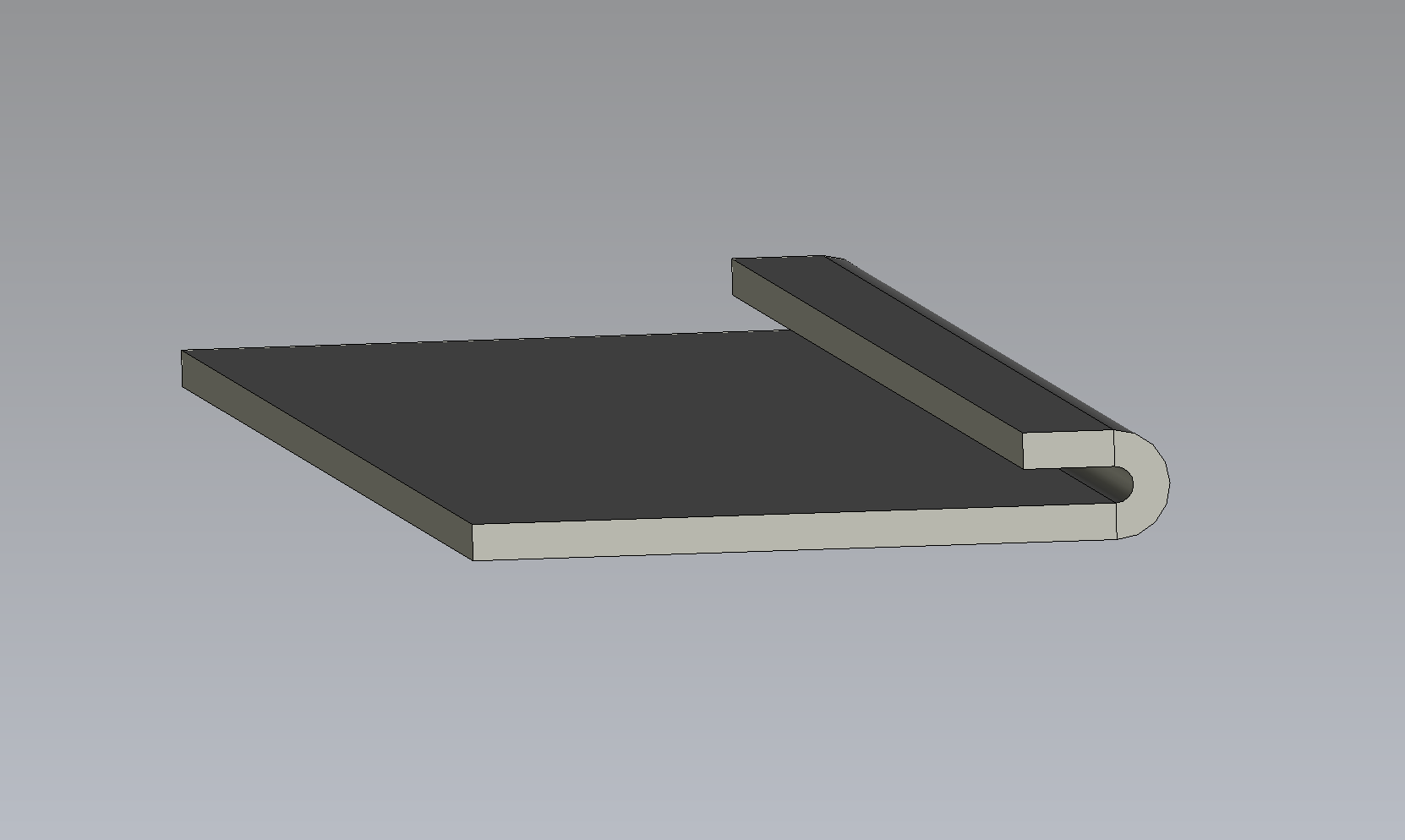

2. Teardrop hem.

A teardrop hem is formed by bending the flange beyond 180 degrees, creating a rounded internal profile. This hem type is commonly used for materials that cannot tolerate a fully crushed hem.

Teardrop hems are well-suited for aluminum and other materials that are prone to cracking during closed hemming.

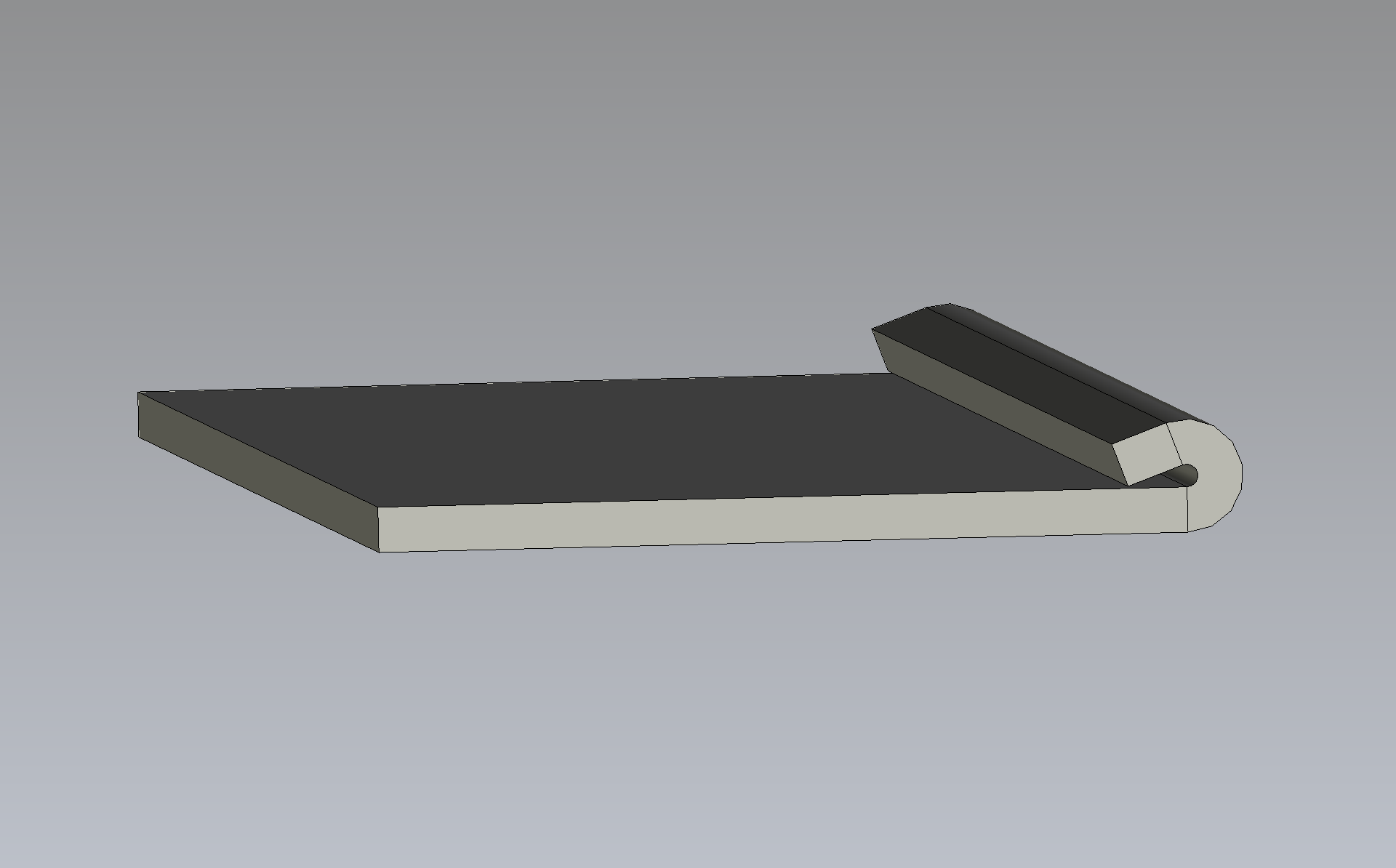

3. Open hem.

An open hem features a soft, curved outer edge and an air pocket in its bend. It’s ideal for handles and other applications that come into contact with people. Like a closed hem, an open hem works best with material thicknesses of .040”-.125” and a flat length that’s a minimum of 4x the material thickness.

open hem works best with material thicknesses of .040”-.125” and a flat length that’s a minimum of 4x the material thickness.

We shape our open hems by forming sheet metal to 145 degrees, then inserting a shim and flattening the material onto itself with the shim in place. Common gap sizes are 060”, .090”, .125”, .187”, and .250”.

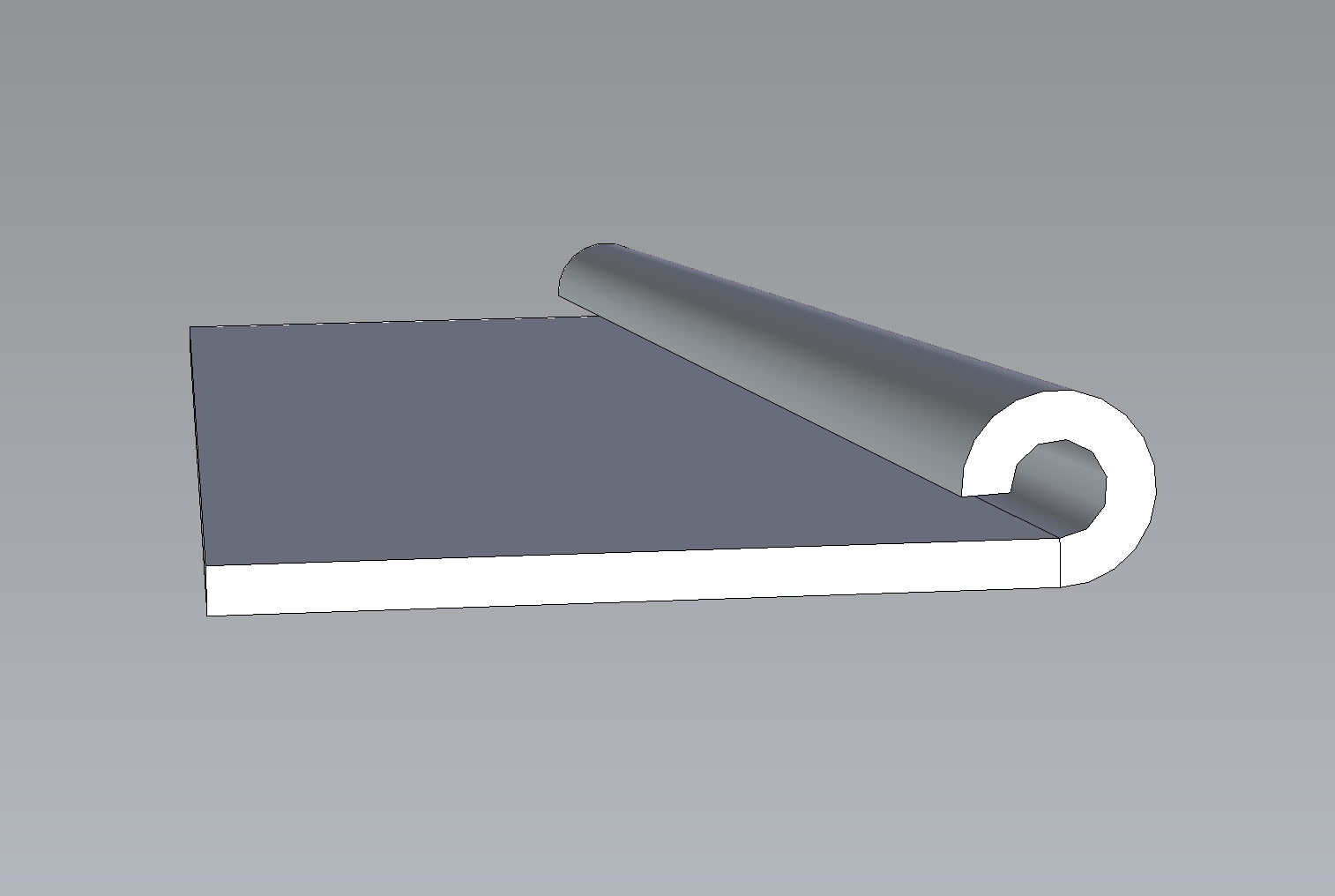

4. Rolled hem.

The purpose of a rolled hem is to eliminate raw sheet metal edges from a part. This type of hem is common for door and figure edges. Rolled hems provide a nice clean look and a safe-to-handle part.

hem is common for door and figure edges. Rolled hems provide a nice clean look and a safe-to-handle part.

Industry Standards and Specifications

Following established hemming guidelines helps ensure consistent forming and reduces the risk of cracking or deformation during fabrication.

- Minimum Inside Diameter: For teardrop hems, the inside diameter should equal the material thickness. For open hems, exceeding the material thickness can lead to loss of roundness.

- Hem Return Length: A minimum of four times the material thickness is advised to prevent fractures.

- Material Thickness Limitations: Closed hems are best suited for materials between 0.040” and 0.125” in thickness. Materials thicker than 0.125” may be prone to cracking during the hemming process.

Design Considerations and Limitations

When designing hems, consider the following to ensure functionality and manufacturability:

- Material Selection: Aluminum and other fragile metals are more susceptible to cracking; therefore, teardrop hems are preferable for these materials.

- Hem Types: Open hems are ideal for parts requiring safe handling, such as handles, due to their smooth, curved edges. Closed hems provide a flush finish but may not be suitable for all materials.

- Process Limitations: Hemming can be time-consuming and may require skilled labor to avoid defects like deformation or damage to the sheet metal. Proper alignment during the hemming process is crucial to maintain consistency and prevent structural issues.

Choosing the right hem improves part safety, strength, and appearance while reducing fabrication risk. If you are unsure which hemming technique is most suitable for your design, our team can help you assess material, geometry, and manufacturing constraints before production begins.