You’ve spent years building your brand and are proud of the quality, reliability, and reputation your logo represents. So when that logo ends up as a blurry decal peeling at the corners, it undercuts the message you’re trying to send.

You’ve spent years building your brand and are proud of the quality, reliability, and reputation your logo represents. So when that logo ends up as a blurry decal peeling at the corners, it undercuts the message you’re trying to send.

Branding on sheet metal should reflect the same craftsmanship as the product itself. Done right, it’s permanent, professional, and unmistakably yours with every detail reinforcing the standards of your brand.

However, sheet metal branding isn’t one-size-fits-all, and the method that works beautifully on brushed aluminum might fail on powder-coated steel. Similarly, a technique that’s perfect for indoor equipment might fade or wear off in outdoor applications.

Successfully integrating branding into sheet metal design means understanding how material type, thickness, finish, and the environment all impact which branding methods deliver the best results.

Let's walk through your options—and what you need to consider for each one.

Table of Contents

Eight Common Sheet Metal Branding Methods

Whether you’re focused on durability, detail, color, or cost, choosing the right sheet metal branding method starts with understanding your priorities.

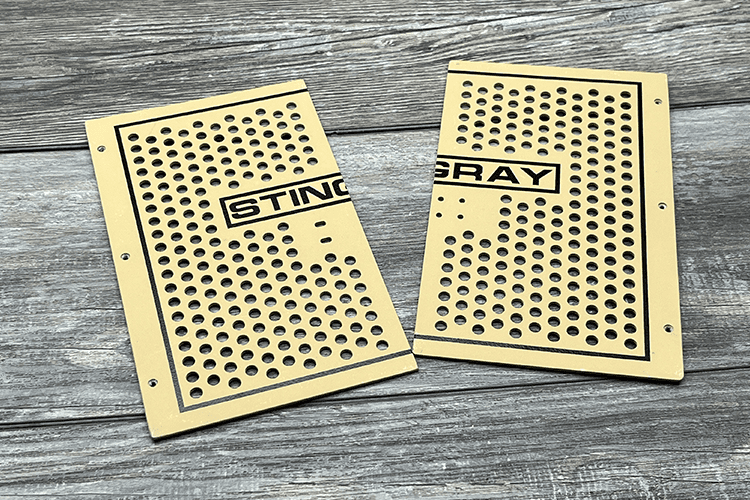

Laser Cutting

Laser cutting creates bold, permanent logos by cutting entirely through the material. This method works well for ventilation panels, decorative grilles, or signage where the cutout itself becomes the design. It's fast and precise, but intricate logos can weaken thin panels if too much material is removed around the cuts.

Stamping, Embossing, and Debossing

Stamping presses a design into the metal to create a raised (embossed) or recessed (debossed) mark. It's permanent, tactile, and gives products a premium, industrial look. However, stamping requires custom tooling, which adds upfront cost. While it can be costly for prototypes or small runs, it's ideal for high-volume production. Once the die is made, the per-part cost drops significantly.

Laser Engraving and Etching

Laser engraving removes a thin layer of material to create high-contrast marks. It's an excellent choice for serial numbers, fine logos, or decorative details. The depth can be adjusted for subtle or bold effects, and the results are permanent. The limitation is that laser engraving is monochrome. While you get contrast between the engraved surface and base material, there is no color.

Chemical Etching

Chemical etching uses acids or other chemicals to remove material in precise patterns. It's well-suited for thin metals and architectural panels where fine detail matters. Unlike laser engraving, color can be added by filling the etched areas with epoxy or paint, making it a good option when you need both detail and color. The process is more involved than laser engraving, but it yields intricate and durable results.

Silkscreen Printing

With silkscreen printing, ink is applied directly to the metal surface, allowing for full-color logos with exact Pantone matching. Silkscreening is one of the most affordable methods for branding sheet metal and works well for graphics that require brand color accuracy. However, the ink can wear over time, especially in high-traffic or outdoor environments. A clear coat helps, but durability is still moderate compared to chemical etching or laser engraving.

Powder Coating and Paint Masking

Powder coating or painting with masking creates high-contrast branding by leaving certain areas bare while coating the rest. It's durable and works well for bold logos or text. Because this method relies on masking accuracy, fine details are limited. However, it's highly effective for large, simple graphics that need to stand out.

Vinyl Decals and Overlays

Vinyl decals offer full-color branding with photographic detail and are easy to apply, remove, or replace. While they're useful for prototyping, temporary identification, or short-term branding needs, they are the least durable option and therefore not a good choice for long-term use. Over time, they can peel, fade, or get damaged in harsh environments.

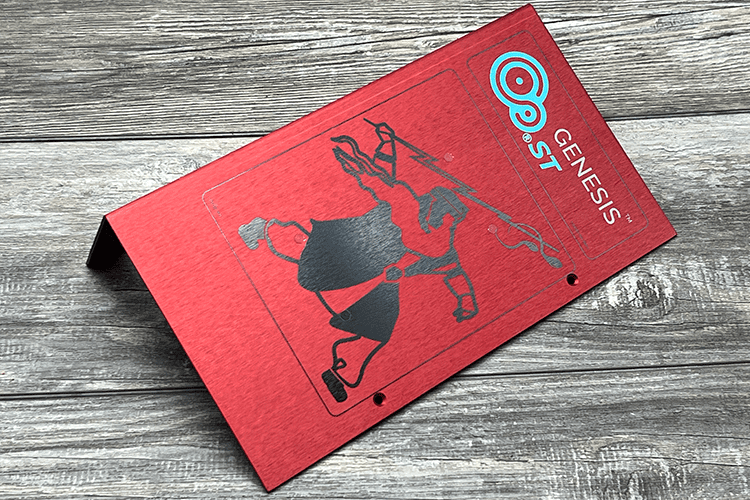

Nameplates and Badges

Unlike the other sheet metal branding methods, nameplates and badges don't manipulate the metal itself—they are separate components attached to the sheet metal part with adhesive, rivets, or screws. They are extremely versatile and can be produced in full color, with embossing, etching, or printing. They're also modular, which means they can be easily swapped out or upgraded, often giving products a more premium look. Durability depends on both the attachment method and the material of the nameplate itself.

Branding Method Comparison

| Method | Durability | Color/Detail Capability | Cost Range | Best For |

|---|---|---|---|---|

| Laser Cutting | High - Permanent | Limited to shapes/silhouettes | $$ | Ventilation panels, bold logos, signage |

| Stamping/Embossing/Debossing | Very High - Permanent | No color, tactile relief only | $$$ (tooling required) | Industrial parts, rugged branding, premium look |

| Laser Engraving/Etching | High - Permanent | High detail, no color (monochrome contrast) | $$ | Serial numbers, fine logos, decorative marks |

| Chemical Etching | High - Permanent | Fine detail, textures, can add color infill | $$$ | Architectural panels, detailed logos |

| Silkscreen | Moderate - Can wear over time | Full color, exact Pantone | $ | Logos, graphics, and brand marks needing color accuracy |

| Powder Coating/Paint Masking | High - Very durable | High-contrast shapes, limited detail | $$ | Large logos, bold text, equipment branding |

| Vinyl Decals/Overlays | Low - Can peel | Full color, photographic detail | $ | Short-term branding, prototyping, temporary ID |

| Nameplates/Badges | High - Depends on fastening | Full color or embossed/etched | $$$ | Premium look, modular branding |

Three Factors That Determine Branding Success

Three factors ultimately determine how well a branding method performs: the type of material, its thickness, and the surface finish. Each influences how the mark looks, how long it lasts, and what processes are even possible.

Consideration #1: Material Choice

If you're working with aluminum, the sky is the limit. It laser cuts cleanly, engraves with crisp contrast, and takes powder coating evenly. Stainless steel is a little more challenging, with laser cutting being slower and more expensive, and printing requiring pretreatment for adhesion. Carbon steel cuts cleanly and quickly, works well for stamping in large runs, and pairs beautifully with powder coating for bold contrast. Copper and brass are ideal for decorative engraving and etching.

Consideration #2: Material Thickness

Although no metal thickness is strictly off limits, certain branding processes perform better within specific ranges. Cutting and forming methods, such as laser cutting, engraving, stamping, or embossing, are most efficient on medium-thickness materials (roughly 0.060"–0.250"). Thin sheet (≤0.060") can still be cut or formed, but delicate logos may reduce structural strength or cause distortion. At the other end of the spectrum, thick plate (≥0.250") slows cutting speeds and makes stamping or embossing impractical.

By contrast, surface-applied methods such as silkscreen printing, powder coating, and nameplates are largely unaffected by material thickness, since they rely on surface adhesion or attachment rather than cutting depth or deformation.

Consideration #3: Surface Finish

The surface finish of your sheet metal affects both how well a branding method will work and how visible the results will be. Here’s how the most common finishes perform:

- Raw or Mill Finish: The most forgiving surface. Works well with laser cutting and stamping without preparation; however, printing requires cleaning or priming for optimal adhesion.

- Brushed or Polished: Ideal for contrast and aesthetics. Laser engraving on these surfaces creates crisp, professional marks that stand out.

- Anodized Aluminum: Excellent for engraving. The laser removes the anodized layer cleanly, revealing bright base metal beneath.

- Powder-Coated or Painted: For the best results, masking should be done before coating is applied, which ensures clean edges and lasting durability.

- Plated Finishes (zinc, chrome, nickel): The most delicate option. Requires specialized processes to prevent cracking or damaging the protective layer.

Branding Do's and Don'ts for Sheet Metal Designers

Branding Do's and Don'ts for Sheet Metal Designers

Understanding branding methods and materials is one thing, but applying that knowledge correctly is another. Here are the most critical guidelines to follow when preparing artwork for sheet metal branding:

- DO use vector artwork. Vector files (.AI, .EPS, .SVG, .DXF) scale cleanly and translate directly into machine code for laser cutting, engraving, and etching. Raster files like JPEGs introduce pixelation and require conversion that can distort your design.

- DO keep stroke widths at or above 0.030" for cutouts. Thinner lines may not cut cleanly, can create weak points in the material, or may be too delicate to survive handling and installation.

- DO simplify logos for laser cutting. What looks sharp on a business card may be too intricate for metal fabrication. Consolidate small details, widen thin elements, and remove unnecessary complexity.

- DON'T place logos near high-stress bends. Branding applied close to formed edges, flanges, or bends can crack, distort, or peel. Leave adequate clearance between branding and any areas subject to deformation.

- DON'T rely on ultra-fine details in masked powder coating. Masking has inherent limitations: tiny gaps, tight spacing, or hairline text often blur or bleed during coating.

- DON'T assume colors will match unless PMS-matched ink or epoxy infill is used. While powder coating offers many color options, precise Pantone matching requires silkscreen inks or epoxy color fills in etched designs.

Acceptable Artwork Formats

Submitting artwork in the correct format prevents delays, ensures accuracy, and avoids costly rework. Here's what we need:

Vector files:

- .AI (Adobe Illustrator)

- .EPS (Encapsulated PostScript)

- .SVG (Scalable Vector Graphics)

- .DXF (Drawing Exchange Format) - Preferred

For laser engraving only, high-resolution black-and-white PNG files are acceptable. Raster files work when the image is essentially "printed" onto the surface, but they can't be used for cutting or masking operations.

Here’s what to avoid:

- Low-resolution JPEGs

- Screenshots or photos of logos

If you're unsure whether your artwork will work, send it over. ASM's design team can review files, flag potential issues, and recommend adjustments before production begins.

Avoiding Common Branding Challenges

Integrating branding into sheet metal sounds straightforward—until it isn't. You now understand the methods available and how materials, thickness, and finish all factor into which options will be most effective. But knowing your choices and avoiding problems in production are two different things.

At Approved Sheet Metal, our engineering and fabrication teams review designs early to spot issues that don’t always show up in CAD. We've navigated these challenges hundreds of times and know which design and process decisions prevent them from becoming problems in the first place.

Design Issues

Sometimes, the branding that looks best in CAD is the hardest to manufacture. Intricate cutouts, fine text, and decorative details might look great on a computer screen but can create structural or visibility issues in production. ASM reviews artwork and geometry up front to catch these problems before fabrication begins.

Loss of Structural Integrity

Intricate logos cut into thin sheet metal can weaken panels, cause warping, or fail under stress. ASM engineers simulate cutout designs and recommend reinforcement strategies, such as adding gussets or flanges, switching to a thicker material gauge, or transitioning to engraving instead of full cut-through when strength is most critical.

Detail Limitations

Fine text or tightly spaced graphics often disappear when laser cut, stamped, or masked for powder coating. ASM reviews artwork early and adjusts for manufacturability—widening strokes, simplifying geometry, or recommending alternative processes such as chemical etching or screen printing when precision detail is essential.

Production Challenges

Some challenges don't appear until parts hit production, when coatings, finishes, or tooling costs behave differently than expected. ASM helps customers plan for these realities through cost modeling and finishes testing before we begin work.

Finish Compatibility

Not every branding method works with every finish. Logos on polished, anodized, or powder-coated surfaces may chip, fade, or lose contrast if the wrong process is chosen. ASM pairs your branding goals with the right method for the job. For instance, laser engraving on anodized aluminum produces sharp, high-contrast marks without damaging the surface.

Tooling and Cost Surprises

Stamping and embossing require custom dies, which can add upfront cost and lead time for initial runs. ASM provides transparent cost modeling and often recommends lower-cost alternatives, such as laser etching, for prototypes or short runs. When volumes justify tooling, ASM helps transition seamlessly to die-based methods for better per-part economics.

Brand Consistency

When products span multiple lines or environments, keeping a unified look takes careful planning. ASM helps customers standardize branding across part families so every piece feels like it came from the same brand—even if it was made years apart.

Color and Durability Trade-offs

Printed logos capture the exact brand colors but may wear off in harsh conditions, while permanent marks, such as engraving and embossing, last indefinitely but lack color options. ASM balances those priorities with hybrid solutions such as etched logos with epoxy color fill or powder-coat masking for bold, lasting color.

Inconsistent Branding Across Parts

Mixing fabrication methods across product lines can lead to subtle variations in appearance. ASM establishes consistent branding standards and provides samples and prototypes, allowing customers to approve the final look before production begins.

Getting Sheet Metal Branding Right From the Start

You don't get a second chance to make a first impression. Branding might be one of the last details teams finalize, but it's one of the first things customers notice on a finished product.

And unlike a marketing campaign or packaging design, branding on sheet metal is permanent. Once a logo is laser cut, etched, or stamped, it remains in place for the product's lifetime. Getting the method, placement, and finish compatibility right from the start is essential.

At Approved Sheet Metal, we bring design, engineering, and fabrication together early so your brand looks as good as your part performs. We review artwork before production, test compatibility with your chosen finish, and model costs transparently. We also deliver samples so you can approve the final result before committing to full runs.

If you're planning a project that involves branding, we'd be happy to help. Contact Approved Sheet Metal to discuss your design and explore which methods will deliver the results you need.

Branding Do's and Don'ts for Sheet Metal Designers

Branding Do's and Don'ts for Sheet Metal Designers