Table of Contents

- 1 Quick Recap: What’s a Sheet Metal Bend Gain?

- 2 The Role of Material Type and Thickness

- 3 Let Us Calculate Your Bend Allowances (or Deductions) for You!

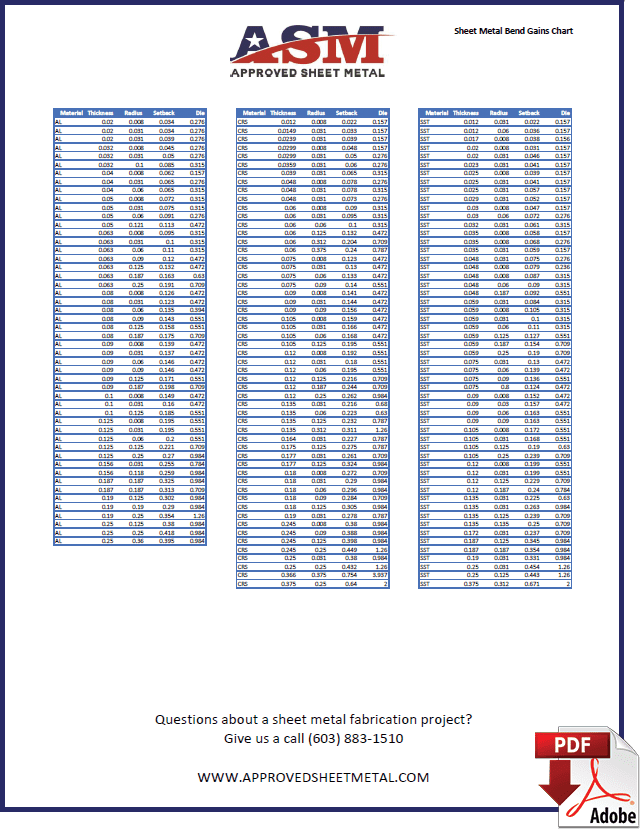

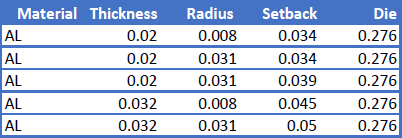

- 4 Sheet Metal Bend Gains Chart

- 5 Sheet Metal Bend Gains FAQ

- 5.0.1 What is a sheet metal bend gain, and why is it important in sheet metal fabrication?

- 5.0.2 Why should design engineers be concerned about sheet metal bend gains?

- 5.0.3 Do design engineers need to calculate sheet metal bend gains themselves?

- 5.0.4 How can I accurately calculate sheet metal bend allowances or deductions?

- 5.0.5 Why should I consider using Approved Sheet Metal's bend gains chart for my sheet metal fabrication projects?

Let us calculate bend gains for you!

Last updated on May 19th, 2025 at 08:28 am

The one thing all sheet metal parts have in common is that they start out flat. Before a prototype becomes the complex structure an engineer designed it to be, it needs to be formed via bending, cutting, punching, and welding. These processes deform and stretch the metal, altering the material length and/or thickness.

If you’re a design engineer, you know that one of the most important DFM considerations for sheet metal fabrication is sheet metal bend gains. You’ve probably adjusted your CAD models for bend gains thousands of times before.

Quick Recap: What’s a Sheet Metal Bend Gain?

When a sheet of metal is bent into an angle, the outer part of the material gets stretched into a curve, while the inner part gets crushed into a V or U shape. The small amount of material that this stretching adds to a part is known as a sheet metal bend gain. Although a bend gain may be tiny, failing to consider bend allowances in the initial design can throw a prototype way out of proportion.

So what’s the best way to calculate an accurate bend allowance or deduction? Leaving this calculation to the design engineer may seem like the ideal solution, but there’s actually a better alternative.

ASM Gets Real About the Journey of Your CAD Model

I’ll be completely honest with you: metal fabrication shops rarely use a design engineer’s sheet metal bend gain calculations. Why? Design engineers don’t always know the exact tool die a manufacturer is going to use for their part. Even a robust program like SOLIDWORKS doesn’t always calculate the right measurements.

The Role of Material Type and Thickness

Material selection is one of the most important variables that influence bend gains—and it’s often overlooked early in the design phase. The mechanical properties of sheet metal, such as yield strength, elongation, and thickness, have a direct impact on how the material behaves when bent. That behavior ultimately determines how much material is “gained” in the bend region.

How Material Affects Bend Gain

- Ductile materials like aluminum or mild steel will stretch more predictably than harder, less ductile materials like stainless steel or titanium. This means they often require less conservative bend deductions.

- Harder materials tend to resist deformation, which leads to greater springback and a larger bend gain due to material stretch.

- Grain direction also plays a role—bending perpendicular to the grain yields better results and less cracking in brittle materials.

How Thickness Influences Bend Gain

- Thicker materials create a larger bend radius, increasing the length of the neutral axis and changing the amount of bend gain.

- For very thin sheets (under 20 ga.), bend gain is minimal and may even be negligible in some cases. For heavier gauges (like 12 ga. or 10 ga.), bend gains can grow significantly and must be tightly controlled.

Real-World Example

Consider a part made from 0.063" 5052-H32 aluminum vs. the same part made from 16 ga. 304 stainless steel:

- With the same tooling and bend angle, the aluminum will experience more stretch and less springback, resulting in a smaller bend gain.

- The stainless part will stretch less but spring back more, requiring compensation through a larger bend deduction or tighter bend radius.

Let Us Calculate Your Bend Allowances (or Deductions) for You!

At Approved Sheet Metal, we aim to make your life (and ours!) easier. We created our own custom sheet metal bend gains chart so engineers and metal fabricators can always be on the same page. This information is our secret sauce, but we’re happy to share it with you.

We’ll always check your CAD models to make sure we meet your end goal dimensions. But the closer your model is to manufacturing reality, the faster and easier it is for us to make your part. You’ll also save yourself the headache of having to rework those CADs. Everyone wins!

If you have any additional questions about sheet metal bend gains, don’t hesitate to give us a call!