Last updated on January 26th, 2026 at 02:42 pm

Stainless steel is one of the most commonly specified materials in precision sheet metal fabrication. It is strong, durable, and highly resistant to corrosion. What many buyers do not realize is that stainless steel can also be a cost effective option when you factor in finishing requirements, material behavior, and long term performance.

Below are three lesser known considerations that can impact both price and lead time when choosing stainless steel for your sheet metal parts.

- Stainless steel can reduce or eliminate finishing costs.

If galvanized steel requires finishing, zinc plating can add several days to lead time and significant cost. For low volume runs, zinc plating alone can cost thousands of dollars. In many cases, the higher material cost of stainless steel is offset by eliminating the need for secondary finishing. Stainless steel also offers superior corrosion resistance over time compared to galvanized steel. -

Thinner stainless steel does not always save money.

Some designers choose 0.047 inch stainless steel to reduce material cost. However, thin stainless steel is prone to warping and distortion, especially during welding. This can lead to longer setup times, additional fixturing, or rejected parts. For welded stainless steel components, 0.074 inch material often produces better results and more consistent pricing. - Stainless steel can replace thicker galvanized steel when strength matters.

We often see requests for 0.25 inch galvanized steel when rigidity is required. In many cases, a thinner stainless steel alternative can meet or exceed the same strength requirements. Using thinner stainless steel can reduce weight, improve weld quality, and simplify fabrication while maintaining structural performance.

Table of Contents

- 1 Stainless vs. Galvanized Steel

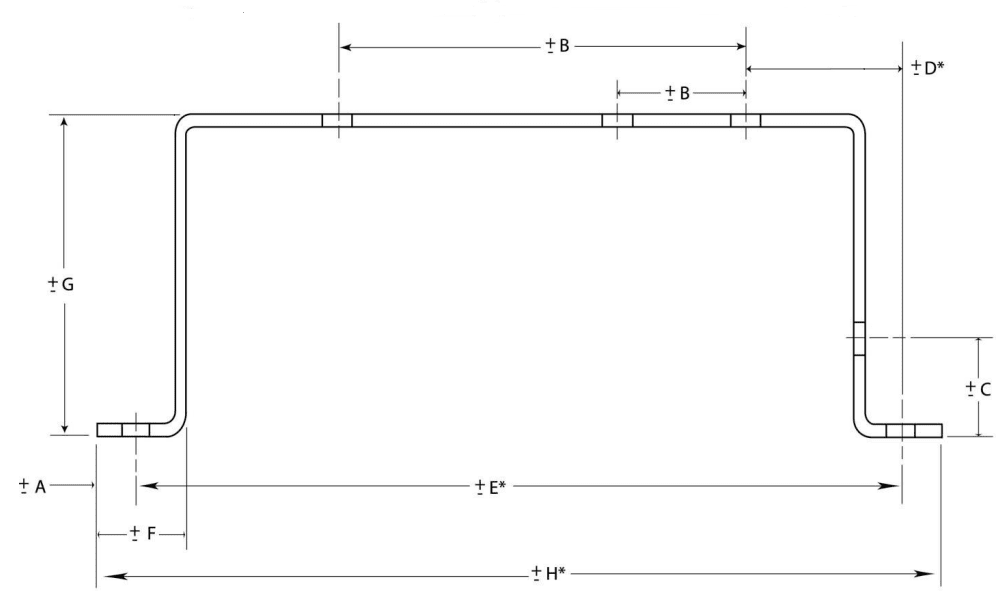

- 2 Recommended Default Sheet Metal Tolerances

- 3 Stainless Steel Fabrication FAQ

- 3.0.1 What are the cost-saving benefits of using stainless steel in sheet metal fabrication?

- 3.0.2 Is thinner stainless steel a cost-effective choice for sheet metal fabrication?

- 3.0.3 How does stainless steel compare to galvanized steel in terms of strength?

- 3.0.4 What are the main differences between stainless steel and galvanized steel?

- 3.0.5 Why do people still use galvanized steel despite stainless steel being superior in many aspects?

Stainless vs. Galvanized Steel

At our sheet metal shop, we regularly help engineers and buyers evaluate material selection. A common question is whether stainless steel or galvanized or zinc-coated steel is the better choice for a given application.

Factors such as corrosion resistance, strength, appearance, and overall cost all play a role when selecting material for a sheet metal part.

In one category, we have zinc-coated steel, commonly referred to as galvanized steel. Galvanized steel is hot dipped in zinc, creating a protective coating that helps resist corrosion.

In the other category, we have stainless steel. Stainless steel is a solid alloy composed of iron, chromium, nickel, and carbon. The chromium content provides corrosion resistance throughout the material, not just at the surface.

These materials are often compared based on corrosion resistance, durability, temperature exposure, tolerance stability, and overall strength.

So why do some projects still use galvanized steel?

The primary advantage of galvanized steel is lower upfront material cost. However, additional finishing requirements, reduced corrosion resistance over time, and welding limitations can offset that savings. For parts that require longevity, clean appearance, or welding, stainless steel is often the more efficient choice.

Need custom fabricated stainless sheet metal parts fast? Approved Sheet Metal supports sheet metal prototyping and low volume production with lead times as short as 2 to 10 days.

Request a quote today.