Table of Contents

- 1 Supply Chain Resilience and Nearshoring

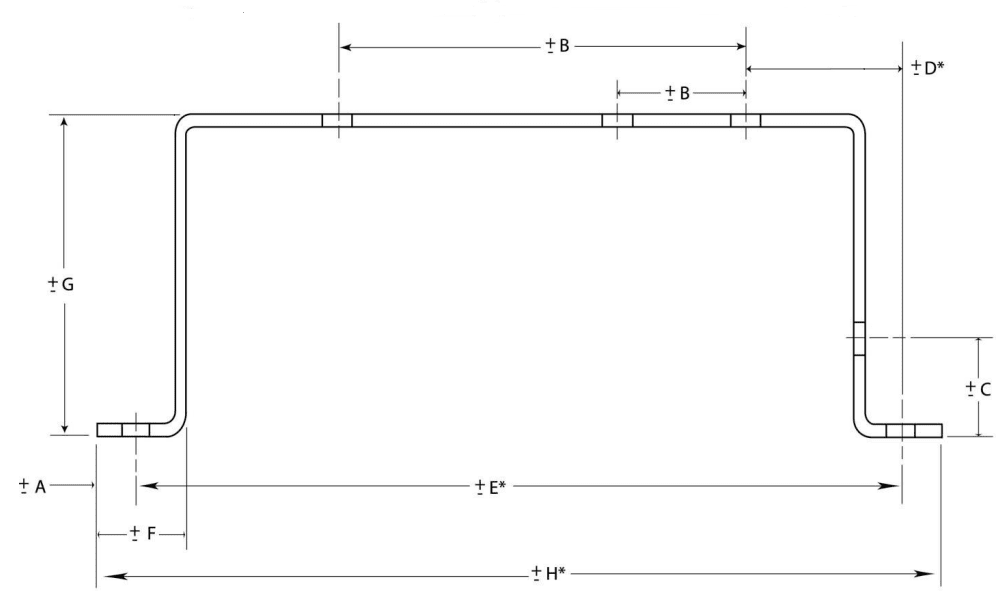

- 2 Recommended Default Sheet Metal Tolerances

- 3 Approved Sheet Metal American Made Parts FAQ

- 3.0.1 Why should I choose American-made sheet metal prototyping over overseas options?

- 3.0.2 Is local manufacturing more expensive compared to overseas resources?

- 3.0.3 What are the advantages of choosing domestic manufacturing for sheet metal prototyping?

- 3.0.4 How does Approved Sheet Metal ensure quality in their fabrication process?

- 3.0.5 How does Approved Sheet Metal handle communication with customers during the manufacturing process?

American-Made Sheet Metal Prototyping and Metal Fabrication

Last updated on April 11th, 2025 at 07:48 am

At Approved Sheet Metal (ASM), we’re proud that 100% of our parts are made in the USA (more specifically, made in the great town of Hudson, New Hampshire).

The assumption is often that American products are expensive compared to overseas resources, but you can actually save money by choosing local manufacturing. Here’s why we love serving you here:

- Local jobs and economic growth. Local manufacturing lets us offer a good living to members of our own community. We currently employee 20 employees in our hometown, and we expect to keep growing!

- Faster delivery. An overseas manufacturer can’t drop off a part at your front door if needed. Shipping and delivery times are significantly shorter when you make your parts domestically.

- Avoid expensive fees and taxes. Often the quoted “cost” of a part doesn’t include shipping and taxes, which can be costly if you’re sending a part overseas and through customs. Save yourself the hidden costs and the headache of dealing with different time zones, difficult communication, and government regulations by buying local.

We love being part of the neighborhood. Community is important to us, both on our team and in our relationships with our customers.

- Quality. When you have deadlines that your team is driving toward, there isn’t time to make things twice. Here at ASM, we believe in making things right the first time. Our rapid sheet metal fabrication process helps us do exactly that.

- Communication. Communicating with customers is an important, and often overlooked, part of manufacturing. We don’t just get it, we get it done! Our state of the art, custom-build inhouse software runs off 3D CAD models. We have the experience and understanding to make any changes needed with a quick phone call or email, and we love to speak with our customers and work hard to keep the information going in both directions. If we have a suggestion or challenge we will provide options rather than issues. 🙂

Supply Chain Resilience and Nearshoring

In today’s volatile global economy, engineers and purchasing teams are prioritizing supply chain resilience more than ever. International disruptions—from port delays to raw material shortages—can put entire production schedules at risk. That’s why more companies are embracing nearshoring by sourcing parts from U.S.-based manufacturers like Approved Sheet Metal.

Why it matters in 2025:

With renewed tariffs on imported metal parts from China and other high-volume regions, many companies are discovering that overseas sourcing no longer guarantees cost savings. Worse yet, once parts are ordered, shipping delays and customs clearance can add weeks to lead times—especially when documentation or inspection issues arise.

Domestic manufacturing provides a smarter alternative:

- Shorter, more reliable lead times with no risk of customs delays

- No surprise tariffs or international fees added after a PO is placed

- Real-time updates from a local partner who’s always a phone call away

By keeping your sheet metal fabrication close to home, you're not only avoiding tariff exposure, but you're also building a more predictable and responsive supply chain. That’s one more reason to partner with a U.S. fabricator who understands your priorities and can deliver quality parts—on time, every time.

Support made-in-the-USA manufacturing with your next sheet metal prototyping project! Request a custom quote from our team.