Last updated on June 26th, 2024 at 08:35 am

Are delays in tooling slowing down your entire production line? When you’re under pressure to cut costs and reduce lead times, tooling can be a major source of frustration. And if you only need a low volume of parts, there’s a good chance it’s not worth the upfront investment.

The next time you find yourself hamstrung by tooling limitations, rely on Approved Sheet Metal to help you save money and speed up production with our bridge production services.

Table of Contents

- 1 The Benefits of Bridge Production

- 2 Identifying Opportunities for Bridge Production

- 3 Sheet Metal Design for Manufacturing

- 4 Sheet Metal Fabrication Bridge Production FAQ

- 4.0.1 How can bridge production benefit my production process?

- 4.0.2 What are the standard use cases for bridge production in sheet metal fabrication?

- 4.0.3 How does bridge production help in overcoming common tooling problems?

- 4.0.4 How does Approved Sheet Metal identify opportunities for bridge production?

- 4.0.5 Can bridge production eliminate the need for extensive inventory in certain situations?

The Benefits of Bridge Production

Bridge production (also known as bridge manufacturing or bridge-to-production) is exactly what it sounds like: a bridge between prototyping and mass production. The goal is to bring a newly launched part or product to market fast using low-volume manufacturing.

There are a couple of standard use cases when bridge manufacturing is an excellent solution for sheet metal fabricated parts:

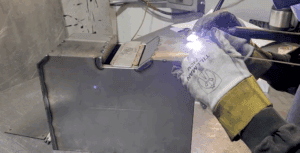

Use Case #1: You’re stuck waiting 6+ weeks for tooling to come in, but in the meantime, you’d like to keep pushing your production process forward. Perhaps you could be using this time to iterate, conduct prototype testing, or even begin moving into production. If you need an urgent solution, Approved Sheet Metal can hand fabricate a low volume of parts (think 100 instead of 10,000) quickly, getting

you parts in hand so that you can get started on next steps and go to market faster.

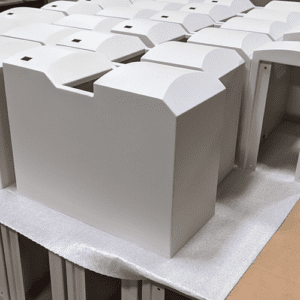

Use Case #2: Your product hasn’t yet gone to market or undergone critical testing, so you’re wary of investing $30,000 for tooling. A stamping house can make your part in one piece, reducing price per part in the long-run, but you only need a low volume of parts at the moment. Rather than investing in the upfront cost of tooling just yet, rely on Approved Sheet Metal to get you the initial parts you need.

In addition to resolving common tooling problems, bridge production reduces the need for extensive inventory. It’s a great solution for product relaunches or new releases of existing parts. You can get a heads

tart while you wait for tooling to arrive, or if your volume is low enough, forgo tooling altogether.

Identifying Opportunities for Bridge Production

The distinction between “prototype” and “production” is often open to interpretation, so we use an advanced algorithm to differentiate between the two. Our algorithm converts 3D CAD models into runtimes, telling us how long it will take to run a line item. If it takes 8 hours or less, it’s a prototype. Anything over 20 hours is production.

The sweet spot in between is likely a candidate for bridge production. If you have a project that's waiting for tooling or needs a fairly low volume of parts, we can help. Request a quote from our metal fabrication shop today.