Last updated on April 2nd, 2025 at 09:51 am

Want to save time and money on your next sheet metal prototype?

At Approved Sheet Metal, we have decades of experience helping our customers transform their brilliant ideas into physical sheet metal prototypes.

We’ve used our expertise to develop a Sheet Metal Fabrication Design for Manufacturing (DFM) eBook, which includes all the best tips we've accumulated over the years.

You'll need to download the eBook for the full set of tips, but we're excited to give you a sneak peek at a few of them in today's blog.

Table of Contents

- 1 Impact of Prototype DFM on Production Scaling

- 2 3 DFM Tips for Sheet Metal Prototypes

- 3 Sheet Metal Design for Manufacturing

- 4 Rapid Sheet Metal DFM FAQ

- 4.0.1 What is the purpose of the Sheet Metal Fabrication Design for Manufacturing (DFM) eBook offered by Approved Sheet Metal?

- 4.0.2 What should I consider regarding uniform wall thickness in my sheet metal prototype design?

- 4.0.3 What guidelines should I follow when incorporating notches and tabs into my sheet metal prototype design?

- 4.0.4 How will my fabricator decide whether to use a drill press or punch press tooling for countersinks in my sheet metal prototype design?

- 4.0.5 How can I access the full set of DFM tips for sheet metal prototypes mentioned in the eBook preview?

Impact of Prototype DFM on Production Scaling

When designing a sheet metal prototype, it’s crucial to consider not only how the part will be manufactured in small quantities but also how it will scale to full production. A well-optimized prototype can significantly reduce manufacturing costs, improve lead times, and minimize design revisions during mass production. Here’s how Design for Manufacturing (DFM) principles impact production scaling:

1. Reducing Costly Design Revisions

Prototyping allows engineers to test form, fit, and function, but if DFM principles aren’t followed early, design flaws may surface in production. Features that are difficult or expensive to manufacture—such as excessive tight tolerances, deep bends, or intricate cutouts—can increase per-unit costs and slow down production.

By designing with scalable manufacturing processes in mind, engineers can avoid costly modifications when transitioning from prototyping to full-scale production.

2. Ensuring Manufacturing Consistency

A prototype may be fabricated with manual operations (such as hand-bent parts or custom machining), but production requires repeatability. Designing with standard bend radii, hole sizes, and material thicknesses ensures the part can be mass-produced using automated processes like CNC press brakes, turret punching, or robotic welding—maintaining quality and reducing variability.

3. Choosing the Right Fabrication Process

During prototyping, laser cutting and manual forming may be practical, but for higher volumes, switching to progressive stamping, turret punching, or roll forming can significantly reduce unit costs. Engineers should evaluate whether their design will allow for these efficient processes at scale.

For example, a prototype part that relies on countersunk holes formed manually with a drill press may need to be reworked to accommodate punch press tooling in full production.

4. Optimizing Material Utilization

Material waste is a key driver of production costs. While small-batch prototypes may not prioritize sheet nesting efficiency, large-scale runs benefit greatly from layouts that minimize scrap. DFM-conscious designs consider how parts will be arranged on a standard sheet size to reduce excess waste.

5. Streamlining Assembly & Secondary Processes

Features such as tabs and slots, self-clinching fasteners (PEM inserts), and modular design simplify assembly and reduce labor costs. Prototypes that are easy to assemble will scale efficiently into production without requiring excessive welding, manual fitting, or post-processing.

By incorporating DFM principles from the prototyping phase, engineers can ensure a smoother transition to high-volume manufacturing, keeping costs down while maintaining product quality and consistency.

3 DFM Tips for Sheet Metal Prototypes

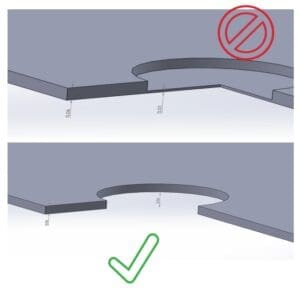

1. Ensure uniform wall thickness

Keep in mind that your sheet metal shop will fabricate your sheet metal prototype from a single piece of material with uniform thickness throughout. We use materials that are a minimum of 0.010” to 0.25” thick.

If you have a complex design, we can help you explore options such as cutting shapes completely through the material or post-machining the material to the desired shape.

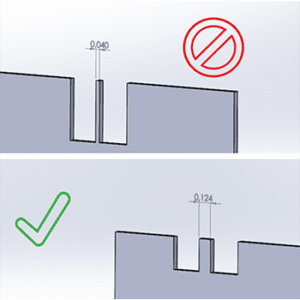

2. Follow strict dimensional guidelines for notches and tabs

If you’re including notches or tabs in your design, follow these guidelines to ensure that your sheet metal prototype can withstand external tensile and flexural forces:

- Notches must be at least the material’s thickness or 0.04”, whichever is greater, and should be no longer than 5x the width of the material

- Tabs must be at least 2x the material’s thickness or 0.126”, whichever is greater, and should be no longer than 5x the width of the material

3. Know how countersinks are applied

When designing countersinks into a sheet metal prototype, keep in mind that there are only two ways countersinks can be applied: via drill press or punch press tooling.

To determine which method is best for your sheet metal prototype, consider your part geometry. If your part has tight angles or features that are difficult to reach with tooling, we’ll likely need to use a drill press. Otherwise, punch press tooling is likely to be the easiest option.

If you have additional DFM questions about your sheet metal prototype, feel free to request a quote quickly and easily on our website. We’ll respond ASAP to discuss the best approach to your part.