Last updated on January 28th, 2026 at 11:26 am

Here at ASM, we believe that efficient sheet metal fabrication starts with simplification.

One of the most effective ways to streamline fabrication is through component consolidation. When feasible, this time and cost-saving strategy allows metal fabrication shops to combine two or more separate components into a single, unified sheet metal part, reducing complexity across manufacturing and assembly.

Read on to learn about the benefits of component consolidation for sheet metal fabrication and what you can do to facilitate the process for your fabricator.

Table of Contents

- 1 How Can You Benefit from Component Consolidation?

- 2 How Can I Help My Fabricator Consolidate My Components?

- 3 Let ASM Take the Guesswork Out of Component Consolidation

- 4 Sheet Metal Component Consolidation FAQ

- 4.0.1 What is component consolidation in sheet metal fabrication?

- 4.0.2 How can component consolidation reduce my overall project costs?

- 4.0.3 What are the benefits of consolidating components for my project’s structural integrity?

- 4.0.4 How can I help my fabricator with component consolidation?

- 4.0.5 Why should I choose ASM for my component consolidation needs?

How Can You Benefit from Component Consolidation?

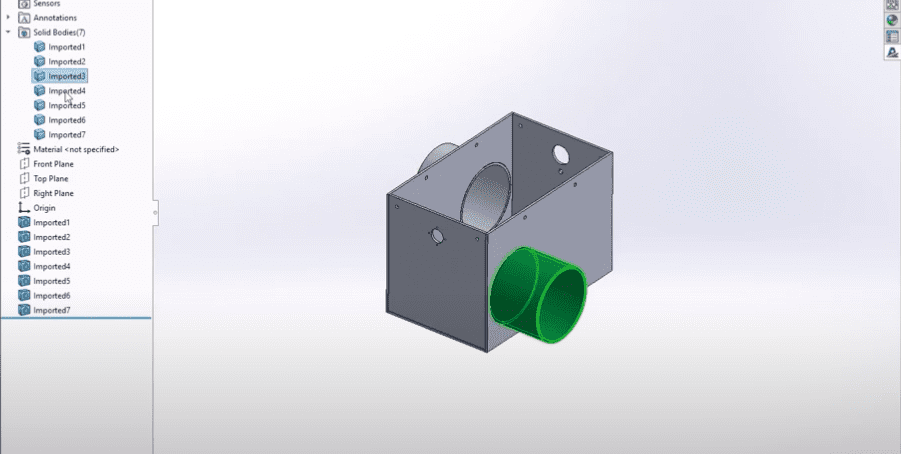

If your project includes multiple sheet metal components that are assembled into a single unit, there is often an opportunity to consolidate those parts into fewer fabricated pieces.

Component consolidation offers an array of advantages, including:

- Reduced assembly time: With fewer parts to assemble, overall assembly time decreases, speeding up production and delivery.

- Lower assembly costs: Fewer individual components mean less labor, fewer assembly steps, and reduced handling costs.

- Improved structural integrity: Consolidated components often outperform multi-part assemblies. Eliminating excessive welds and fasteners reduces potential weak points and improves overall strength and rigidity.

- Enhanced appearance: Component consolidation minimizes visible seams and joints, resulting in a cleaner, more professional-looking finished part.

- Streamlined fabrication processes: Fewer parts reduce the number of fabrication steps required, simplifying workflows and lowering the risk of production errors.

- Weight reduction: Consolidation allows fabricators to remove redundant material and joining features, reducing overall part weight—an important advantage in aerospace and automotive applications.

- Greater design flexibility: Designing fewer, more integrated components gives engineers more freedom to optimize geometry, add features, and improve part performance.

- Overall cost savings: Material efficiency, reduced tooling, lower labor requirements, and simplified production all contribute to meaningful cost savings across the project lifecycle.

How Can I Help My Fabricator Consolidate My Components?

Component consolidation works best when it is considered early in the design process. Instead of viewing an assembly as a collection of individual parts, designers should evaluate how features can be integrated into fewer fabricated components while still meeting functional requirements.

Above all, it’s important to design assemblies with component consolidation in mind. Rather than looking at an assembly as a series of individual parts that will eventually need to be put together, designers should approach each as a larger whole so that they can more ably identify fitment issues.

In practice, you can help your fabricator consolidate your components by remembering some simple dos and don’ts:

- Don’t send assembly components over individually using separate line items or entirely separate purchase orders.

- Don’t have different components from the same assembly fabricated with different metal fabrication shops just because it’s cheaper.

- Do provide assembly files that contain explicit directions about which components you’d like consolidated and context about each component’s end use.

- Do trust all components from a single assembly to one shop so that nothing gets lost in translation.

In addition to reducing the chance that you’ll need to fix your designs or spend more to remake parts, following this advice will give your fabricator the chance to identify opportunities for consolidation (and further savings) that you might have missed.

Let ASM Take the Guesswork Out of Component Consolidation

At ASM, we help customers identify and execute component consolidation opportunities that reduce cost and simplify production without sacrificing performance. Our team reviews assemblies with manufacturability in mind and recommends design changes that streamline fabrication and assembly.

If you are working on a sheet metal assembly and want to explore consolidation opportunities, our team is ready to help. Request a quote today and let us help you save time and money on your next project.

Request a quote today to save time and money on your next sheet metal project!